What Makes CNC Machining Revolutionizing Modern Automotive Manufacturing?

What Makes CNC Machining Revolutionizing Modern Automotive Manufacturing?

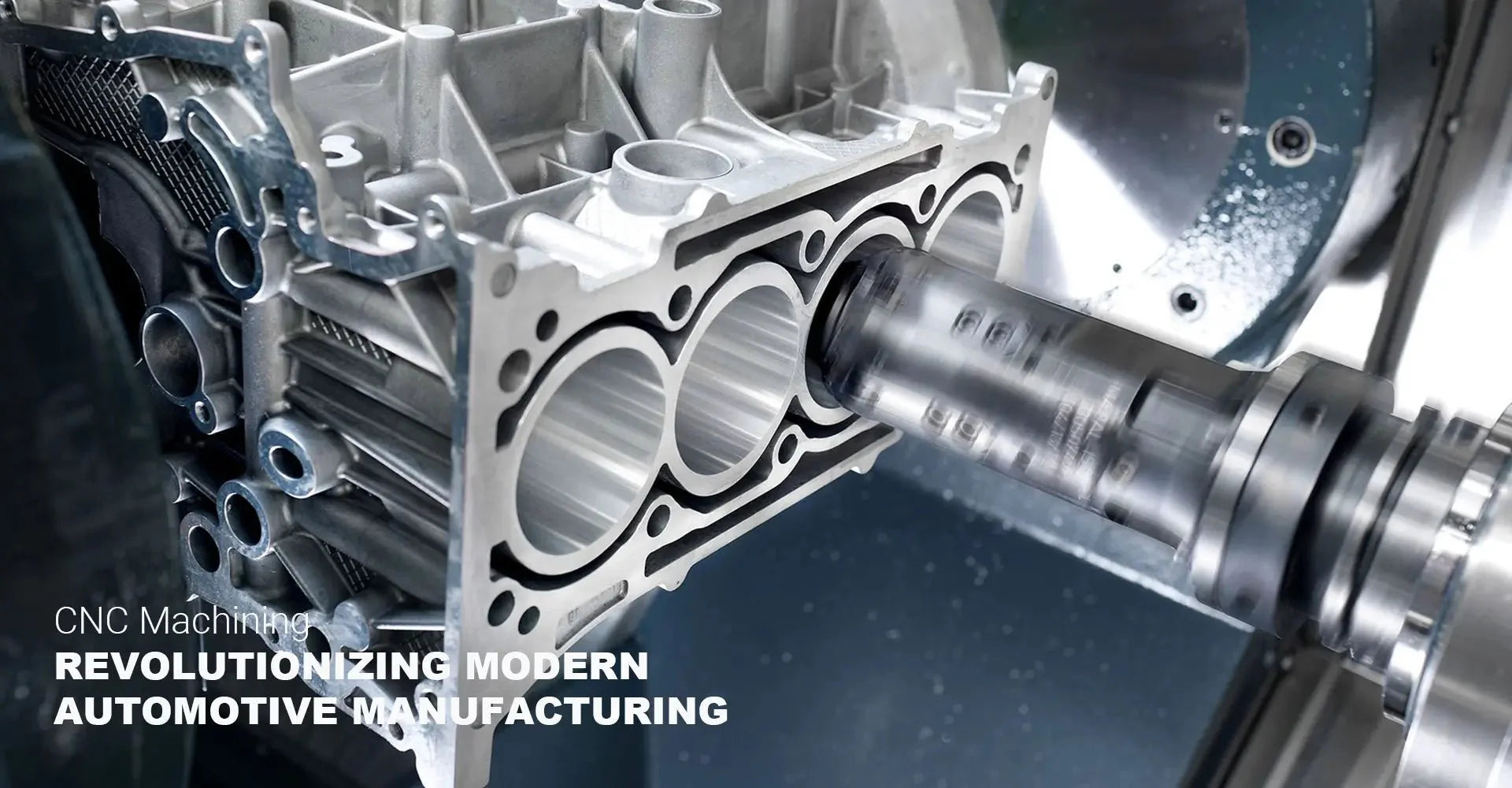

In today's rapidly evolving automotive industry, precision and efficiency are no longer just advantages – they're necessities. CNC machining has emerged as a transformative force, revolutionizing how automotive parts are manufactured and setting new standards for quality and productivity in the automotive sector.

Key Insights:

- The automotive sector commands 47% of all industrial robotics sales in North America

- Market projections show a remarkable $1.95 billion growth from 2021 to 2026

- Precision capabilities reach up to ±0.001 inches in tolerance

As we delve into the world of CNC machining in automotive manufacturing, we'll explore how this technology is reshaping the industry, improving production efficiency, and driving innovation in vehicle component manufacturing.

Table of Contents

- What Exactly is CNC Machining in Automotive Manufacturing?

- Why is CNC Machining Crucial for Modern Automotive Parts?

- Which Automotive Parts are Commonly Manufactured Using CNC Machining?

- How Does CNC Machining Compare to Traditional Manufacturing Methods?

- Conclusion

What Exactly is CNC Machining in Automotive Manufacturing?

The foundation of modern automotive manufacturing excellence lies in understanding CNC machining services. Computer Numerical Control (CNC) machining represents a sophisticated manufacturing process where pre-programmed computer software dictates the movement of factory machinery and tools.

In automotive manufacturing, this technology translates complex 3D designs into precise physical components through automated cutting, milling, and shaping processes. The integration of computer-controlled operations ensures unprecedented accuracy and repeatability in part production.

This revolutionary technology combines advanced software programming with precision engineering, enabling manufacturers to produce complex automotive components with tolerances as tight as ±0.001 inches. The process involves multi-axis machining capabilities, real-time monitoring systems, and sophisticated quality control measures.

Why is CNC Machining Crucial for Modern Automotive Parts?

The automotive industry's reliance on CNC turning and milling processes has become increasingly critical as vehicles become more sophisticated. Modern automobiles demand components with superior precision, consistency, and reliability – requirements that CNC machining perfectly addresses.

The impact of CNC machining on automotive manufacturing is evident through:

- Unprecedented precision in component production

- Significant reduction in manufacturing time

- Consistent quality across large production runs

- Ability to produce complex geometries

- Reduced material waste and improved cost-efficiency

The automotive industry's strict quality standards and high-volume production requirements make CNC machining not just beneficial, but essential for maintaining competitiveness in today's market.

Which Automotive Parts are Commonly Manufactured Using CNC Machining?

The versatility of automotive CNC machining extends across virtually every aspect of vehicle production. From engine components to exterior body parts, CNC machining plays a crucial role in manufacturing various automotive components.

Common applications include:

- Engine blocks and cylinder heads

- Transmission housings and gearbox components

- Brake system components

- Suspension parts

- Custom aftermarket modifications

Each of these components requires specific machining processes, tolerances, and quality control measures. Modern CNC machines excel in producing these parts with consistent quality and precision, meeting the demanding standards of automotive manufacturers.

How Does CNC Machining Compare to Traditional Manufacturing Methods?

When comparing CNC machining to traditional manufacturing methods, the advantages become clearly apparent in several key areas:

The integration of CNC machining has revolutionized automotive manufacturing by introducing levels of precision, efficiency, and repeatability that were previously unattainable through traditional methods.

Conclusion

The role of CNC machining in automotive manufacturing continues to evolve and expand, driven by technological advancements and increasing demands for precision and efficiency. As the automotive industry moves toward more complex and sophisticated vehicles, the importance of CNC machining will only grow.

Key Takeaways:

- CNC machining has transformed automotive manufacturing through precision and automation

- The technology enables the production of complex parts with unprecedented accuracy

- Future trends indicate continued growth and innovation in CNC machining applications