3D Printing Service

Our online 3D printing services offer high-quality custom parts and prototypes tailored to fit any project. Whether you need a one-off prototype or a full production run, we support a variety of technologies, including FDM, SLS, SLA, and MJF, with quick quotes.

FDM

(Fused Deposition Modeling)

-Fast & Affordable Prototyping

- Dimensional accuracy of ±0.5% with a lower limit: ±0.5mm

- Lead times from 1-2 business days

SLS

(Selective Laser Sintering)

-Functional Prototyping & Low-run Production

- Dimensional accuracy of ±0.3% with a lower limit: ±0.3mm (±0.012")

- Lead times from 3 business days

SLA

(Stereolithography )

-Visual Prototyping

- Dimensional accuracy of ±0.3% with a lower limit: ±0.3mm (±0.012")

- Lead times from 3 business days

MJF

(Multi Jet Fusion)

-Functional Prototyping & Low-run Production

- Dimensional accuracy of ±0.3% with a lower limit: ±0.3mm (±0.012")

- Lead times from 2 business days

3D Printing Capacilties

Our comprehensive 3D printing services encompass FDM, SLS, SLA, and MJF technologies, delivering exceptional precision and quality for both rapid prototyping and functional end-use parts. With advanced capabilities in high-resolution printing and diverse material options, we provide reliable solutions for complex designs across various industries including automotive, aerospace, and consumer product

| Parameter | FDM | SLS | SLA | MJF |

|---|---|---|---|---|

| Standard Tolerance | ±0.15% (min. ±0.2 mm) | ±0.3% (min. ±0.3 mm) | ±0.1% (min. ±0.1 mm) | ±0.3% (min. ±0.3 mm) |

| Best Achievable Tolerance | ±0.1% (min. ±0.15 mm) | ±0.2% (min. ±0.2 mm) | ±0.05% (min. ±0.05 mm) | ±0.2% (min. ±0.2 mm) |

| Layer Thickness | 0.1 - 0.3 mm | 0.08 - 0.15 mm | 0.025 - 0.1 mm | 0.08 mm |

| Build Volume | 300 × 300 × 300 mm | 300 × 300 × 300 mm | 500 × 500 × 500 mm | 380 × 285 × 380 mm |

| Minimum Wall Thickness | 0.8 mm | 0.7 mm | 0.5 mm | 0.8 mm |

| Minimum Feature Size | 1.0 mm | 0.8 mm | 0.3 mm | 0.8 mm |

| Surface Roughness (Ra) | 8-15 μm | 10-18 μm | 1-3 μm | 8-12 μm |

| Common Materials | ABS, PLA, PETG, Nylon, TPU | Nylon PA12, PA11, Glass-filled | Standard, Tough, Flexible, Castable, High Temp Resins | Nylon PA12, PA11 |

| Support Structures | Required (breakaway or soluble) | Not required (self-supporting powder) | Required (breakaway) | Not required (self-supporting powder) |

| Typical Lead Time | 2-5 days | 3-7 days | 2-5 days | 3-6 days |

3D Printing Materials

We provide comprehensive material options including engineering plastics like ABS and Nylon, plus metals such as Aluminum and Stainless Steel for industrial 3D printing applications.

| Material Category | Material | Key Properties | Typical Applications |

|---|---|---|---|

| Plastics |

ABS

ABS

|

Good strength, durability, heat resistance | Functional prototypes, enclosures, automotive parts |

PLA

PLA

|

Easy to print, biodegradable, rigid | Concept models, educational projects, displays | |

Nylon (PA)

Nylon (PA)

|

Strong, flexible, wear resistant | Gears, hinges, functional components | |

TPU

TPU

|

Flexible, elastic, impact resistant | Gaskets, seals, protective cases | |

| Metals |

Stainless Steel 316L

Stainless Steel 316L

|

Excellent corrosion resistance, strong | Marine components, chemical equipment, food processing |

Stainless Steel 17-4PH

Stainless Steel 17-4PH

|

High strength, heat treatable | Tools, industrial parts, high-stress components | |

Aluminum 6061

Aluminum 6061

|

Good strength-to-weight ratio, machinable | Automotive parts, frames, structural components |

3D Printing Suface Finishing

Enhance your 3D printed parts with our surface finishing services including bead blasting, polishing, and powder coating. We provide professional post-processing to improve appearance, functionality, and durability for both plastic and metal 3D printing projects. More Surface Finishes>>>

|

|

|

|

Bead Blasting Creates uniform matte texture on 3D printed parts |

Polishing Removes layer lines for smooth, glossy surfaces |

Powder Coating Durable colored finish with excellent protection |

|

|

|

|

Anodizing Hard, corrosion-resistant finish for metal parts |

Electroless Nickel Plating Uniform metallic coating for complex geometries |

Brushed Finish Creates directional texture on metal surfaces |

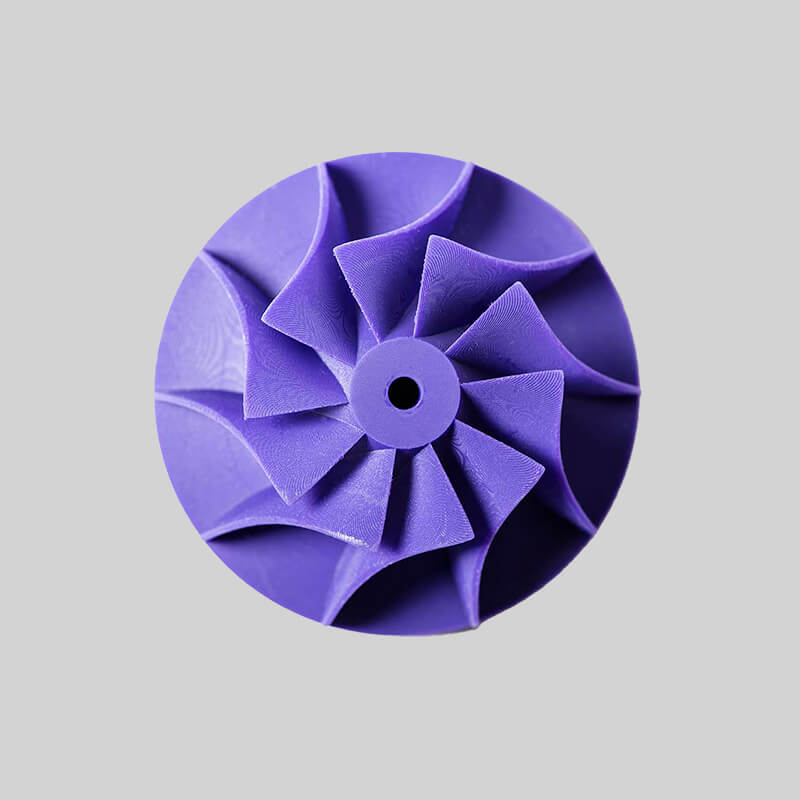

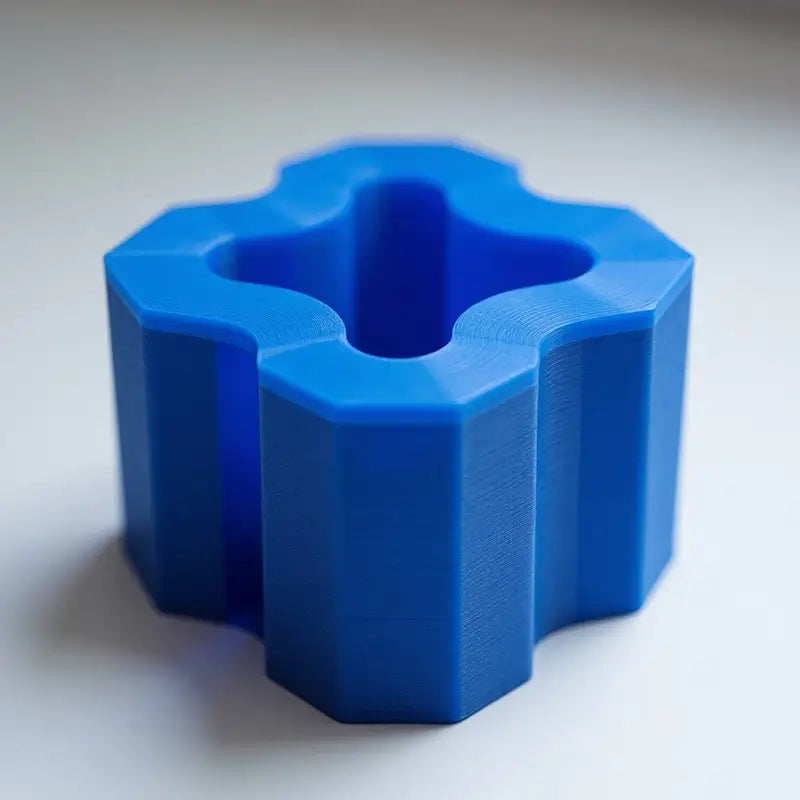

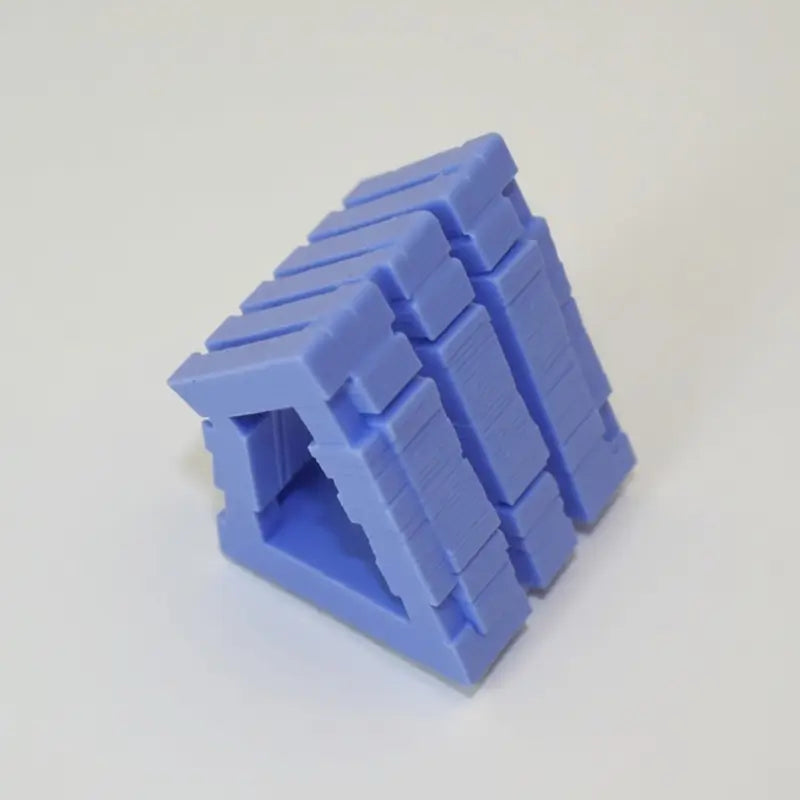

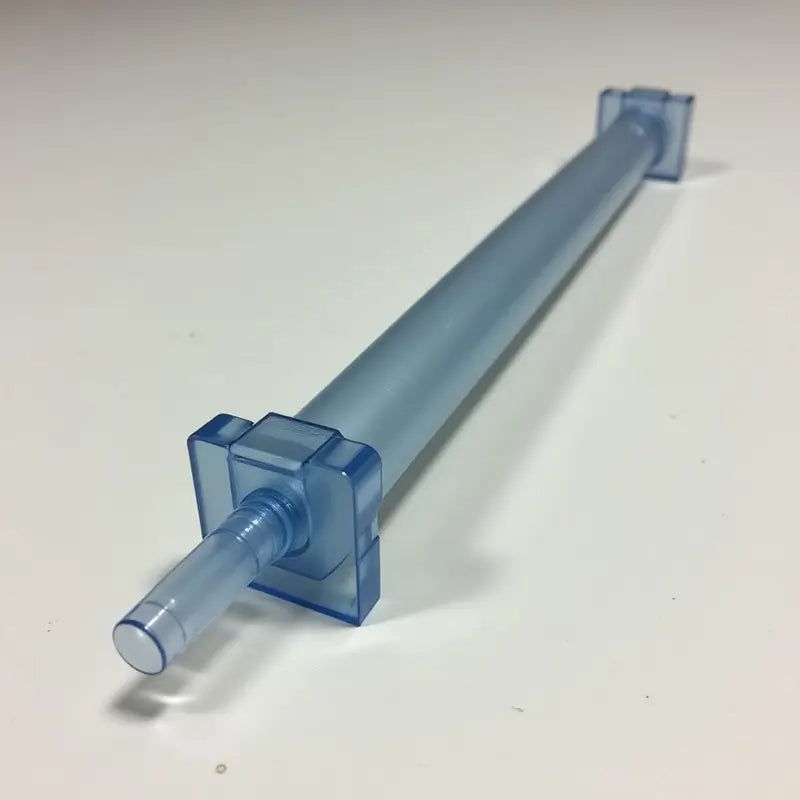

Gallery Of 3D Printing Parts

With over 30,000 customers across industries like aerospace, defense, robotics, medical, automotive, and electronics, we bring extensive 3D printing expertise to meet diverse needs. From rapid prototyping to full production, we handle visual aids, concept models, functional prototypes, injection molds, tooling, jigs, and even durable end-use parts.

FAQ

MOST FREQUENT QUESTIONS AND ANSWERSQ1: What materials can be used in 3D printing?

A1: Common materials include thermoplastics (PLA, ABS, PETG), photopolymer resins, and powders like nylon (PA 12) or TPU. Composite materials like carbon fiber-reinforced plastics and metals can also be used in certain technologies.

Q2: What industries benefit from 3D printing?

A2: 3D printing is widely used in aerospace, automotive, healthcare (for implants and prosthetics), consumer goods, and manufacturing for creating prototypes, custom parts, and even end-use products.

Q3: How accurate are 3D printed parts?

A3: Accuracy depends on the technology used. SLA and MJF are known for high precision, often reaching tolerances of ±0.1 mm, making them ideal for detailed designs. FDM and SLS offer good accuracy but may require post-processing for better surface finish.

Q4: What are the limitations of 3D printing?

A4: Some limitations include slower production times for large-scale manufacturing, limited material options compared to traditional methods, and the need for post-processing (such as sanding, painting, or support removal) for certain technologies.

Q5: How long does it take to 3D print something

A5: The time to print an object depends on its size, complexity, layer thickness, and the 3D printer's speed. Small objects can take a few hours, while larger, more complex designs may take several days.

Q6: Is 3D printing cost-effective?

A6: For small-batch production, prototyping, or custom parts, 3D printing is very cost-effective compared to traditional manufacturing. However, for large-scale production, traditional methods like injection molding are generally more cost-efficient.

Q7:What post-processing is required for 3D printed parts?

A7: Post-processing can include removing support structures, sanding, painting, polishing, or curing (for resin-based parts). Metal parts may require additional heat treatments or machining for improved strength and finish.

Q8:Can 3D printing create functional, moving parts?

A8: Yes, 3D printing can produce fully functional parts, including moving mechanisms, in a single print. Technologies like SLS, MJF, and FDM are commonly used to print hinges, gears, and other mechanical components without the need for assembly.

Q9: What is the largest object that can be 3D printed?

A9: The size limit of 3D printed objects depends on the printer’s build volume. For industrial machines, this can be up to several meters in size. Larger parts can be printed in sections and then assembled. Technologies like FDM and large-format SLA are often used for big prints