From Rapid Prototyping to High-Volume Production

Sheet Metal Fabrication

Transform your designs into high-quality, functional parts with our professional sheet metal fabrication services. We deliver custom sheet metal parts and assemblies with precision, speed, and reliability. Whether you need rapid prototyping or high-volume production, we support your project with expert engineering, a wide selection of materials and finishes, and a commitment to fast turnaround times.

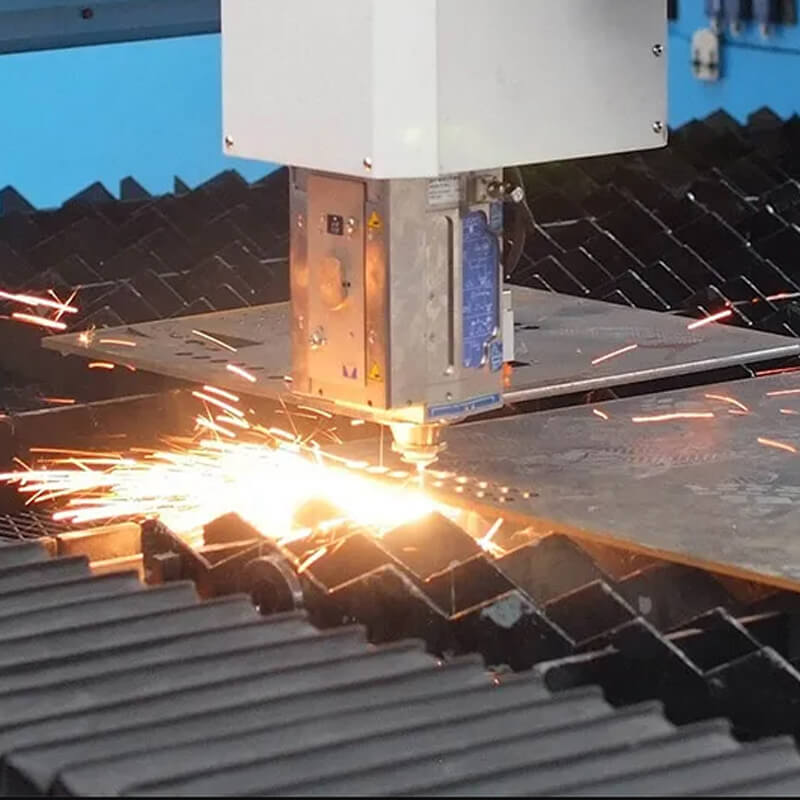

Precision Cutting

Our precision laser cutting service produces intricate parts with clean edges and tight tolerances (±0.1mm), minimizing secondary finishing.

- Capabilities & Materials: We cut stainless steel, aluminum, and carbon steel, from 0.5mm to 12mm thick.

Need custom cutting parts?

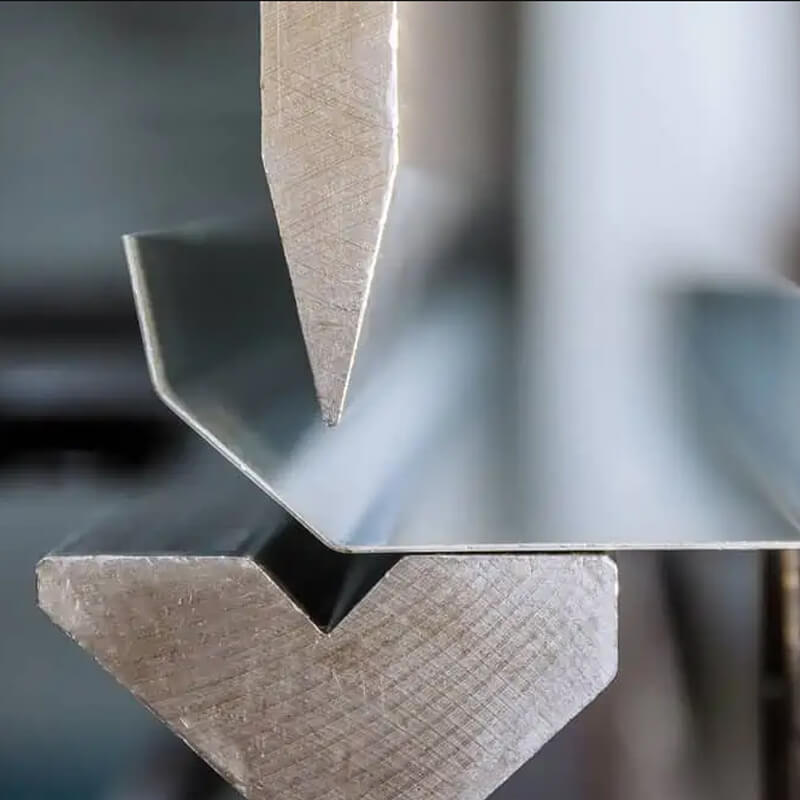

CNC Bending

Our CNC bending service creates precise, repeatable bends for enclosures and brackets, ensuring perfect fit in assembly.

- Capabilities & Materials: We form U-shapes, V-shapes, and box forms in materials like aluminum and steel (1mm-6mm thick).

Require precise sheet metal bending?

Metal Stamping

Our metal stamping service is ideal for large runs, providing efficient production of uniform parts with excellent repeatability.

- Capabilities & Materials: Suitable for low-carbon steel, aluminum, and copper, typically up to 4mm thick.

Planning high-volume sheet metal production?

Professional Welding

Our professional welding services deliver strong, clean welds to ensure the structural integrity of your sheet metal assemblies.

- Capabilities & Materials: We weld components from 1mm to 8mm thick, using techniques suited to the material and application.

Need to join custom sheet metal parts?

Precision Sheet Metal Fabrication Capabilities

Review our key precision sheet metal fabrication parameters andmanufacturing standards below. These technical specifications ensure your project is built for performance, reliability, and on-time delivery.

| Capability Category | Specifications & Standards |

|---|---|

| Standard Tolerances |

Laser Cutting Positioning: ±0.1 mm Bending Angle: ±0.5° Bending Dimension: ±0.13 mm Flatness: ≤ 0.2 mm / 300 mm |

| Production Capacity |

Max. Laser Cutting Size: 3000 x 1500 mm Max. Bending Length: 2500 mm Max. Bending Force: 250 Ton Volume Compatibility: From 1-piece prototype to 10,000+ batch production |

| Key Process Parameters (DFM Guide) |

Minimum Bend Radius: Equal to material thickness (t) Minimum Laser-Cut Hole Diameter: ≥ Material thickness (t) Minimum Flange Width: ≥ 4t + V-die width / 2 |

| Quality Control & Inspection |

Key Measurement Tools: Optical Comparators, Calipers, Micrometers Coordinate Measuring Machine (CMM): Available for complex profiles First Article Inspection (FAI): Strictly followed per project |

| Standard Lead Time |

Rapid Prototyping: 5-10 working days Small to Medium Batch Production: 2-4 weeks |

Materials For Sheet Metal Fabrication

Choose the optimal material for your project. Explore the properties and applications of common sheet metal materials below to ensure performance, durability, and value. If you need any customized materials, please get in touch with us.

| Visual | Material Type & Key Properties | Common Grades & Standards | Typical Applications & Notes |

|---|---|---|---|

|

Aluminum Alloys Lightweight, good strength-to-weight ratio, excellent corrosion resistance, and high thermal/electrical conductivity. |

6061-T6, 5052-H32, 3003, 7075 (ASTM, ISO, GB standards) |

Applications: Enclosures, chassis, brackets, heat sinks, consumer electronics casings. Note: Excellent for prototyping and applications requiring weight reduction. |

|

Stainless Steel High strength, superior corrosion and heat resistance, hygienic surface, with good formability and weldability. |

304 (A2), 316 (A4), 430, 201 (AISI, SUS, DIN standards) |

Applications: Food processing equipment, medical devices, marine hardware, architectural trim. Note: 316 offers enhanced corrosion resistance for harsh environments. |

|

Carbon Steel (Mild Steel) Cost-effective, high strength and hardness, good machinability and weldability. Requires surface treatment to prevent rust. |

Q235 (SPHC), DC01, 1008, 1010 (AISI, JIS, EN standards) |

Applications: Industrial frames, cabinets, brackets, automotive components. Note: The most economical choice for high-volume production of structural parts. |

|

Copper & Copper Alloys Outstanding electrical and thermal conductivity, good corrosion resistance, and antimicrobial properties. |

Copper (C11000), Brass (C26000), Phosphor Bronze (C5191) |

Applications: Electrical contacts, RFI shielding, heat exchangers, decorative components. Note: Softer material; requires careful handling to avoid scratches during fabrication. |

Sheet Metal Surface Finishing Services

Enhance functionality and aesthetics.Our sheet metal surface finishing services protect parts from corrosion and wear, while providing the desired visual appeal. Select the right finish for your application.

| Process & Visual | Applicable Materials | Key Characteristics & Benefits | Typical Applications |

|---|---|---|---|

Powder Coating

|

Carbon Steel, Aluminum, Stainless Steel | Durable, corrosion-resistant finish. Available in a wide range of colors and textures (matte, gloss, textured). Environmentally friendly process with high material utilization. | Outdoor enclosures, architectural panels, automotive parts, home appliances, furniture. |

Anodizing

|

Aluminum and its alloys | Enhances corrosion and wear resistance. Creates a porous surface that can be dyed in various colors (clear, black, gold, etc.) before sealing. Maintains metallic appearance. | Consumer electronics casings, automotive trim, marine hardware, aerospace components. |

Brushing (Hairline)

|

Stainless Steel, Aluminum, Brass | Produces a uniform satin finish with directional texture. Effective at concealing fingerprints and minor scratches. Offers a modern, non-reflective aesthetic. | Appliance panels (ovens, refrigerators), elevator interiors, signage, decorative trim. |

Polishing (Mirror)

|

Stainless Steel, Aluminum, Copper, Brass | Achieves a high-gloss, reflective mirror-like surface. Improves cleanliness and provides a premium, decorative finish. Can be applied to varying degrees of reflectivity. | Decorative architectural features, luxury goods trim, food processing equipment, reflective panels. |

Electroplating

|

Steel, Copper, Brass, etc. | Deposits a thin layer of metal (e.g., Zinc, Nickel, Chrome) for corrosion protection, increased surface hardness, wear resistance, or improved solderability and appearance. | Fasteners, connectors, automotive components, plumbing fixtures, hardware tools. |

Simple & Reliable Sheet Metal Fabrication Process

From your idea to finished parts, our streamlined workflow ensures quality, transparency, and on-time delivery.

Upload & Review

Submit your CAD files. Our engineers conduct a free Design for Manufacturability (DFM) review and provide initial feedback

Quote & Plan

Receive a detailed, itemized quotation with material and process options. We clarify all specifications to align on expectations.

Approve & Produce

Upon your approval, your project enters our managed precision manufacturing workflow with scheduled updates.

Quality & Delivery

Parts undergostrict quality inspectionsbefore being carefully packaged and shipped, ensuring on-time arrival.

Ready to begin? Start with Step 1 today.

Upload Your CAD File & Get a QuoteFAQ

MOST FREQUENT QUESTIONS AND ANSWERSQ1: What types of materials can be used in sheet metal fabrication?

A1: We commonly work with materials such as stainless steel, mild steel, aluminum, copper, and brass. Each material has unique properties, such as strength, corrosion resistance, and workability, making them suitable for different applications.

Q2: What are the typical tolerances for sheet metal fabrication?

A2: Typical tolerances range from ±0.1 mm to ±0.5 mm, depending on the complexity of the design, material type, and manufacturing process used. We strive to maintain tight tolerances to ensure high precision and quality.

Q3: What are the maximum and minimum thicknesses that can be processed?

A3: We handle sheet thicknesses ranging from 0.5 mm to 12 mm, depending on the specific process. For bending, the ideal range is typically 1 mm to 6 mm. Please let us know your specific requirements so we can recommend the best options.

Q4: Can you provide custom surface finishes for fabricated parts?

A4: Yes, we offer a variety of surface finishes, including powder coating, anodizing, plating, brushing, polishing, and sandblasting. Surface treatment options can enhance the product's appearance, corrosion resistance, and durability based on your needs.

Q5: What quality control measures do you have in place?

A5: We implement strict quality control measures at every stage of production, including material inspection, in-process checks, and final dimensional verification. Our team uses precision measurement tools and follows ISO standards to ensure product quality

Q6: What is your typical lead time for sheet metal fabrication?

A6: Lead time varies depending on the complexity and volume of the order. Standard projects typically take 2-4 weeks from order confirmation to delivery. For urgent orders, we can offer expedited production schedules.

Q7: Can you support both low-volume and high-volume production?

A7: Yes, we support both low-volume prototyping and high-volume production. Our flexible manufacturing setup allows us to efficiently handle a variety of order sizes while maintaining consistent quality.

Q8: How do you ensure parts meet customer specifications?

A8:We work closely with customers from the design stage to understand their requirements and specifications. After production, we provide full inspection reports, including dimensional measurements and surface finish details, to verify compliance.

Q9: What design features should be considered for sheet metal parts?

A9: Designs should account for material type, thickness, bend radius, and edge conditions to avoid issues like warping or cracking. We recommend keeping a consistent bend radius and minimizing complex cuts for better manufacturability.