3/4/5 Axis CNC Machining Service

3 Axis CNC Machining

Best For: Prototyping, simpler parts, 2.5D geometries, high-volume production of non-complex components.

Key Advantage: Most cost-effective solution for a wide range of applications

4 Axis CNC Machining

Best For: Parts requiring features on multiple sides (e.g., drilling holes on a cylinder), camshafts, and continuous profiling.

Key Advantage: Dramatically reduces setup time vs. 3-axis by allowing rotation around the X-axis.

5 Axis CNC Machining

Best For: Highly complex, organic shapes (impellers, turbines, aerospace structures), and parts requiring machining of compound angles.

Key Advantage: Ultimate precision and surface finish on complex parts by machining in a single setup..

Our 3, 4 & 5-Axis Machining Capabilities

Whether your project requires the efficiency of 3-axis, the flexibility of 4-axis, or the complexity of 5-axis machining, our fleet of advanced CNC centers is equipped to deliver.

| Parameter | 3-Axis Machining | 4-Axis Machining | 5-Axis Machining |

|---|---|---|---|

| Max. Travel (X, Y, Z) | 800 x 500 x 400 mm | 700 x 450 x 400 mm | 600 x 400 x 300 mm |

| Max. Part Weight | 150 kg | 100 kg | 50 kg |

| Positioning Accuracy | ± 0.012 mm | ± 0.010 mm | ± 0.008 mm |

| Repeatability | ± 0.006 mm | ± 0.005 mm | ± 0.003 mm |

| Spindle Speed | 12,000 rpm | 15,000 rpm | 18,000 rpm |

| Control System | Siemens 828D | Siemens 840D | Heidenhain TNC 640 |

| Capability | Specification | Notes |

|---|---|---|

| Standard Tolerance | ± 0.025 mm | Tighter tolerances available on request |

| Standard Surface Finish | Ra 0.8 - 1.6 μm (as-machined) | Ra 0.4 μm achievable with finishing |

| Minimum Hole Size | Ø 0.5 mm | |

| Maximum Part Size | 800 x 500 x 400 mm | For single-setup parts |

| Inspection Equipment | CMM, Calipers, Micrometers, Optical Comparators | Full First Article Inspection (FAI) reports provided |

| Material Hardness | Up to 45 HRC(Basic) | Harder materials require special tooling |

| Lead Time | 5-15 working days | Depending on complexity and quantity |

CNC Machining Materials & Surface Finishes

We’ve got a wide selection of CNC materials for your parts and 50+finishes to meet both your functional and aesthetic needs

3/4/5 Axis CNC Machining Materials

We cater to these industries by providing rapid prototypes and production parts using a wide range of materials, including:

CNC Machining Surface Finishes

We offer instant quotes for a wide range of post-machining surface finishes. It Includes: Smooth Machining, Fine Machining, Anodizing Type II & Type III...

Design Guidelines for CNC Machining

Optimize your parts for cost-effective CNC manufacturing with our design guidelines. Our engineers provide design-for-manufacturability (DFM) feedback before production, helping you move smoothly from prototyping to production.

Start Your Project in 3 Simple Steps

Upload your CAD files to receive instant pricing and expert DFM analysis, select from our extensive material options and production capabilities, then approve your order for fast, precision manufacturing and reliable delivery. Get Started

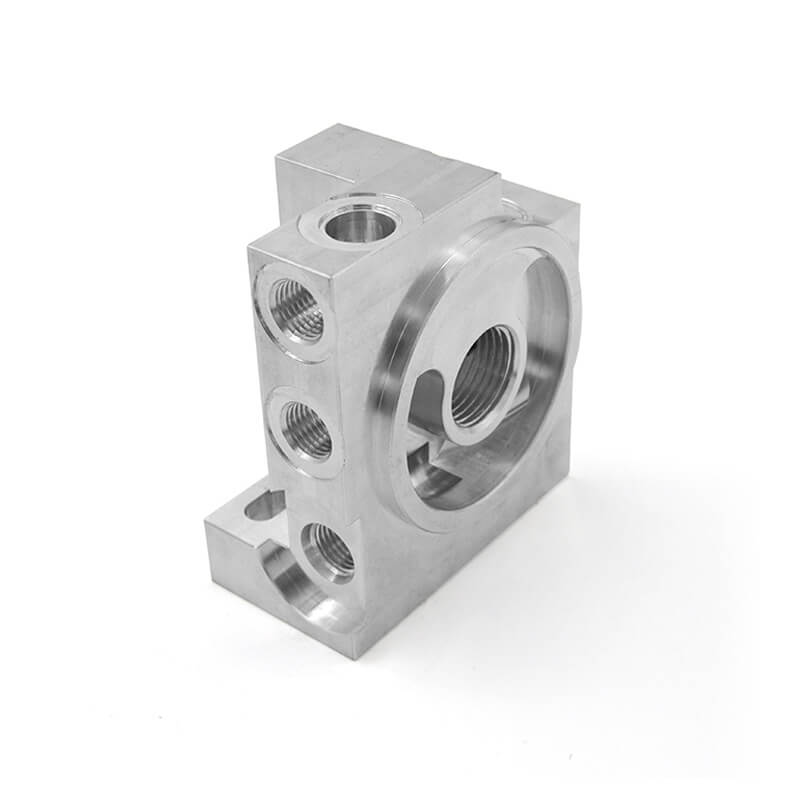

Gallery of 3/4/5 Axis CNC machined parts

FAQ

MOST FREQUENT QUESTIONS AND ANSWERSQ1: What is the difference between 3-axis, 4-axis, and 5-axis CNC machining?

A1: 3-axis machining moves along the X, Y, and Z axes, ideal for simple parts. 4-axis adds rotation for working on multiple sides, while 5-axis provides two rotational axes for complex and precise geometries.

Q2: Which CNC machining option is the most cost-effective?

A2: 3-axis machining is usually the most cost-effective for simple shapes, but for complex parts requiring fewer setups, 4-axis or 5-axis machining may save time and reduce overall costs.

Q3: When should I choose 4-axis machining over 3-axis?

A3: Choose 4-axis machining for components with features on multiple sides or cylindrical parts that require continuous rotation for better precision.

Q4: What are the benefits of using 5-axis CNC machining?

A4: 5-axis machining allows for complex shapes, reduces multiple setups, and ensures superior surface finishes, making it ideal for high-precision industries like aerospace and automotive.

Q5: Is 5-axis machining always the best choice?

A5: No, 5-axis is best for complex geometries. If your parts have simple profiles, 3-axis or 4-axis machining is sufficient and more cost-effective.

Q6: What materials can be processed using 3/4/5 axis CNC machines?

A6: They can process a wide range of materials, including aluminum, stainless steel, titanium, brass, and various plastics, depending on the project’s requirements.

Q7: How does the machining time differ between 3, 4, and 5-axis?

A7: 3-axis machining is faster for simple shapes, but 4-axis and 5-axis machines reduce repositioning time for complex parts, which can result in shorter lead times for intricate components.

Q8:What type of parts is 5-axis CNC machining best for?

A8: It’s best for parts with intricate surfaces, deep pockets, or complex curves, such as turbine blades, impellers, and aerospace components.

Q9: Can 4-axis or 5-axis machines improve product accuracy?

A9: Yes, these machines allow for fewer setups, minimizing errors and ensuring higher accuracy, especially for parts with tight tolerances.