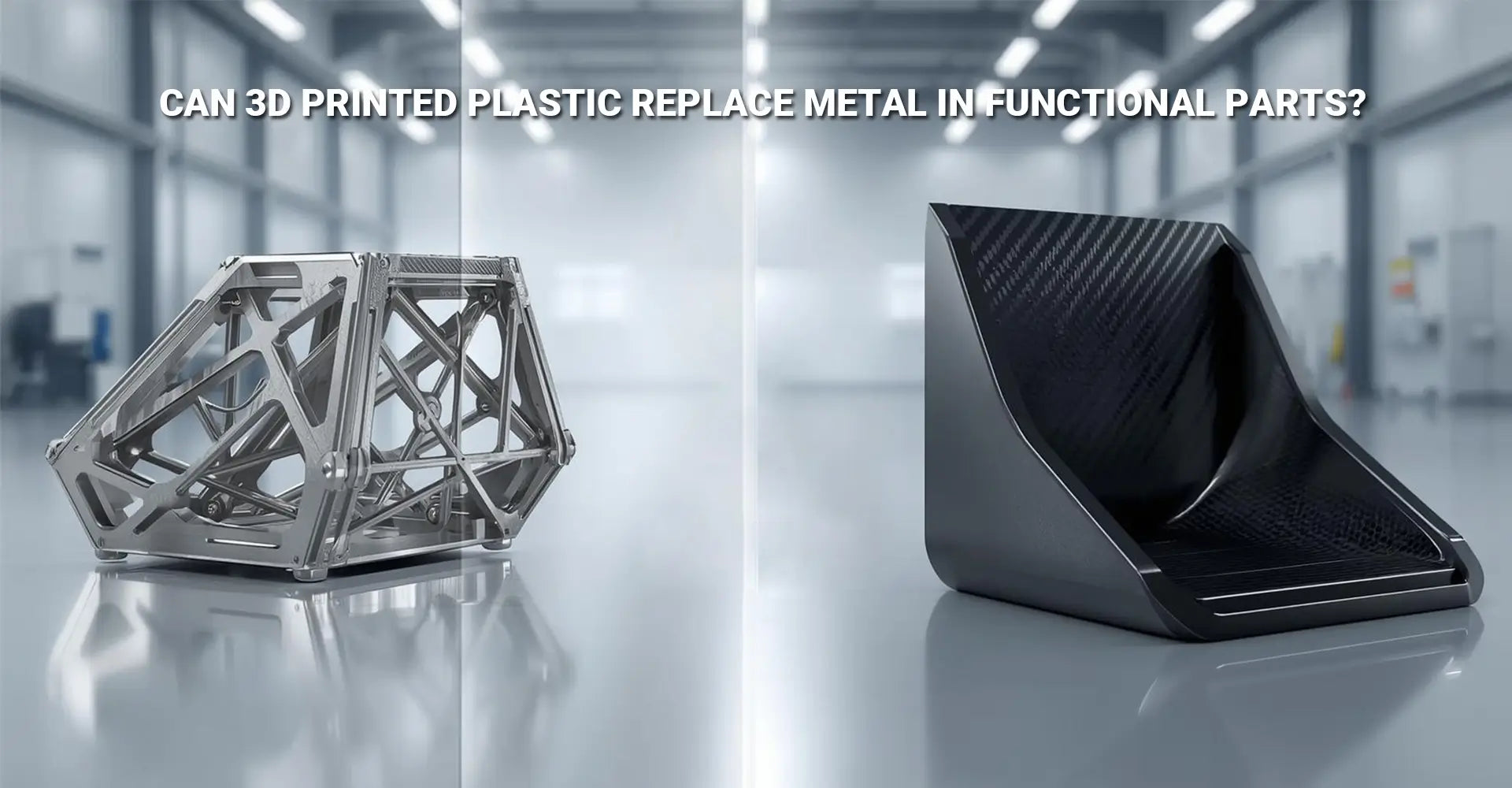

Can 3D Printed Plastic Really Replace Metal in Functional Parts?

Can 3D Printed Plastic Really Replace Metal in Functional Parts?

Engineers and manufacturers face a critical decision when selecting materials for functional parts. Therefore, the choice between plastic and metal 3D printing can make or break project budgets. However, recent advances in composite filaments are challenging traditional assumptions about material performance.

Quick Answer: Carbon fiber-reinforced nylon achieves 89 MPa tensile strength, approaching aluminum's performance at 90% lower cost. Meanwhile, metal 3D printing delivers 268-345 MPa strength but costs 10-50x more per part. Furthermore, proper print orientation affects strength more than raw material specifications.

This comprehensive analysis examines real-world test data from engineering communities. Additionally, we'll explore when expensive metal printing justifies its premium price. Moreover, you'll discover which materials deliver the best strength-to-cost ratio for your specific applications.

Table of Contents

- Which 3D Printing Filament Actually Delivers Metal-Level Strength?

- How Much Does Real-World Metal vs Plastic 3D Printing Cost Your Project?

- What Makes Carbon Fiber Filaments Compete with Aluminum Parts?

- Why Does Print Orientation Matter More Than Material Specs for Strength?

Which 3D Printing Filament Actually Delivers Metal-Level Strength?

Material selection for functional parts requires understanding actual performance data rather than marketing claims. Consequently, engineers must compare real-world test results to make informed decisions. Furthermore, the 3D printing filament vs metal strength comparison reveals surprising gaps between specifications and practical applications.

Key Finding: No conventional plastic filament matches dense metal strength in absolute terms. However, advanced composites like carbon fiber-reinforced nylon approach aluminum in specific strength ratios. Additionally, polycarbonate excels in impact resistance while maintaining reasonable tensile properties.

Testing data shows significant variations in strongest 3D printing filament performance across different applications. For instance, carbon fiber-reinforced nylon (PA-CF) achieves 89 MPa tensile strength compared to aluminum's 268-345 MPa. Nevertheless, when considering weight-to-strength ratios, composites often provide adequate performance for non-critical applications. Moreover, specialized 3D printing plastics offer unique advantages in specific environments. Polycarbonate handles extreme temperatures up to 117°C, while PETG provides excellent chemical resistance. Therefore, material selection depends heavily on application requirements rather than pure strength numbers.

How Much Does Real-World Metal vs Plastic 3D Printing Cost Your Project?

Cost comparison 3D printing materials reveals dramatic differences beyond initial material prices. Subsequently, equipment, post-processing, and labor costs multiply the total project expense. Hence, understanding complete cost structures helps justify material selections.

Critical Numbers: Metal powder costs $500-800/kg versus $20-80/kg for premium filaments. Additionally, metal printers start at $150,000 compared to $300-3,000 for desktop FDM systems. Furthermore, post-processing adds significant time and expense to metal parts.

Comprehensive cost analysis shows plastic vs metal 3D printing involves multiple expense categories. First, material costs create a 10-25x price difference per kilogram. Second, equipment investment requirements vary dramatically between technologies. Third, post-processing demands differ significantly between materials. Metal parts require stress relief treatments, support removal, and often heat treatment procedures. In contrast, plastic parts typically need minimal finishing work. Additionally, rapid prototyping with plastics enables faster iteration cycles at lower costs. Therefore, many manufacturers reserve metal printing for applications requiring extreme performance characteristics.

What Makes Carbon Fiber Filaments Compete with Aluminum Parts?

Carbon fiber filament vs aluminum strength comparison reveals interesting performance characteristics in lightweight applications. Consequently, aerospace and automotive industries increasingly evaluate composite alternatives. Moreover, advanced composite formulations continue improving strength-to-weight ratios.

Performance Data: Carbon fiber composites achieve 80% of aluminum's load capacity at 30% of the weight. Additionally, they offer superior vibration dampening and corrosion resistance. Furthermore, composite parts eliminate thermal expansion issues common with metal components.

Composite 3D printing materials bridge the performance gap between traditional plastics and metals through strategic reinforcement. Carbon fiber-reinforced nylon combines the base polymer's toughness with carbon fiber's exceptional stiffness. Consequently, these materials excel in applications requiring high strength-to-weight ratios. For example, drone manufacturers report that carbon fiber brackets handle 80% of aluminum's load while weighing 70% less. Additionally, composite parts resist fatigue better than many metal alternatives in cyclic loading situations. However, surface finish considerations become important since carbon fibers can create texture variations. Therefore, proper post-processing techniques ensure acceptable cosmetic appearance for visible components.

Why Does Print Orientation Matter More Than Material Specs for Strength?

Layer adhesion creates anisotropic properties that dramatically affect part performance regardless of material choice. Subsequently, 3D printing material properties vary significantly based on build orientation. Hence, proper part positioning often matters more than selecting premium materials.

Critical Impact: Z-axis strength can be 60-80% lower than XY-axis strength in FDM parts. Additionally, metal DMLS parts show only 10-15% variation compared to 30-50% in plastic prints. Furthermore, nylon vs metal 3D printing strength differences narrow when considering optimal orientations.

Anisotropy remains 3D printing's most significant limitation across all technologies and materials. 3D printing tensile strength chart data shows dramatic variations based on load direction relative to layer orientation. For instance, parts loaded perpendicular to layers fail at much lower stresses than those loaded parallel to layers. This phenomenon affects functional 3D printing material selection decisions more than raw material strength values. Additionally, professional 3D printing services understand these limitations and design parts accordingly. Smart engineers orient critical stress paths along the strongest axes while using support structures strategically. Therefore, successful functional parts require both appropriate material selection and intelligent orientation planning.

Conclusion

The Contents of Conclusion

Material selection for 3D printed functional parts requires balancing performance requirements against cost constraints. Advanced composite filaments provide adequate strength for 80% of applications at dramatically lower costs than metal alternatives. However, extreme temperature or stress requirements still necessitate metal printing despite higher expenses. Furthermore, print orientation and part design significantly impact performance regardless of material choice. Therefore, successful projects combine appropriate material selection with intelligent design practices and proper manufacturing orientation.

Key Takeaways:

- Carbon fiber composites approach aluminum performance at 90% lower cost

- Print orientation affects strength more than material specifications

- Metal printing justifies costs only for extreme performance requirements

- Composite materials excel in weight-sensitive applications

External Links Recommendation

Additional Resources:

[strongest 3D printing filament][^1]

[plastic vs metal 3D printing][^2]

[3D printing material properties][^3]

[composite 3D printing materials][^4]

[functional 3D printing material selection][^5]

[cost comparison 3D printing materials][^6]

---

[^1]: Discover the latest advancements in 3D printing filaments that offer superior strength and durability for your projects.

[^2]: Explore the pros and cons of plastic and metal 3D printing to make informed decisions for your manufacturing needs.

[^3]: Understanding these properties is crucial for selecting the right material for your 3D printing projects.

[^4]: Exploring composite materials can enhance your 3D printing capabilities and improve the quality of your prints.

[^5]: Explore this link to understand the criteria and options for selecting materials that enhance the functionality of 3D printed parts.

[^6]: This resource provides insights into the cost differences among various 3D printing materials, helping you make informed decisions.