Which is Better for Your Project: 3D Printing or CNC Machining

Which is Better for Your Project: 3D Printing or CNC Machining - A Complete Comparison Guide for 2024?

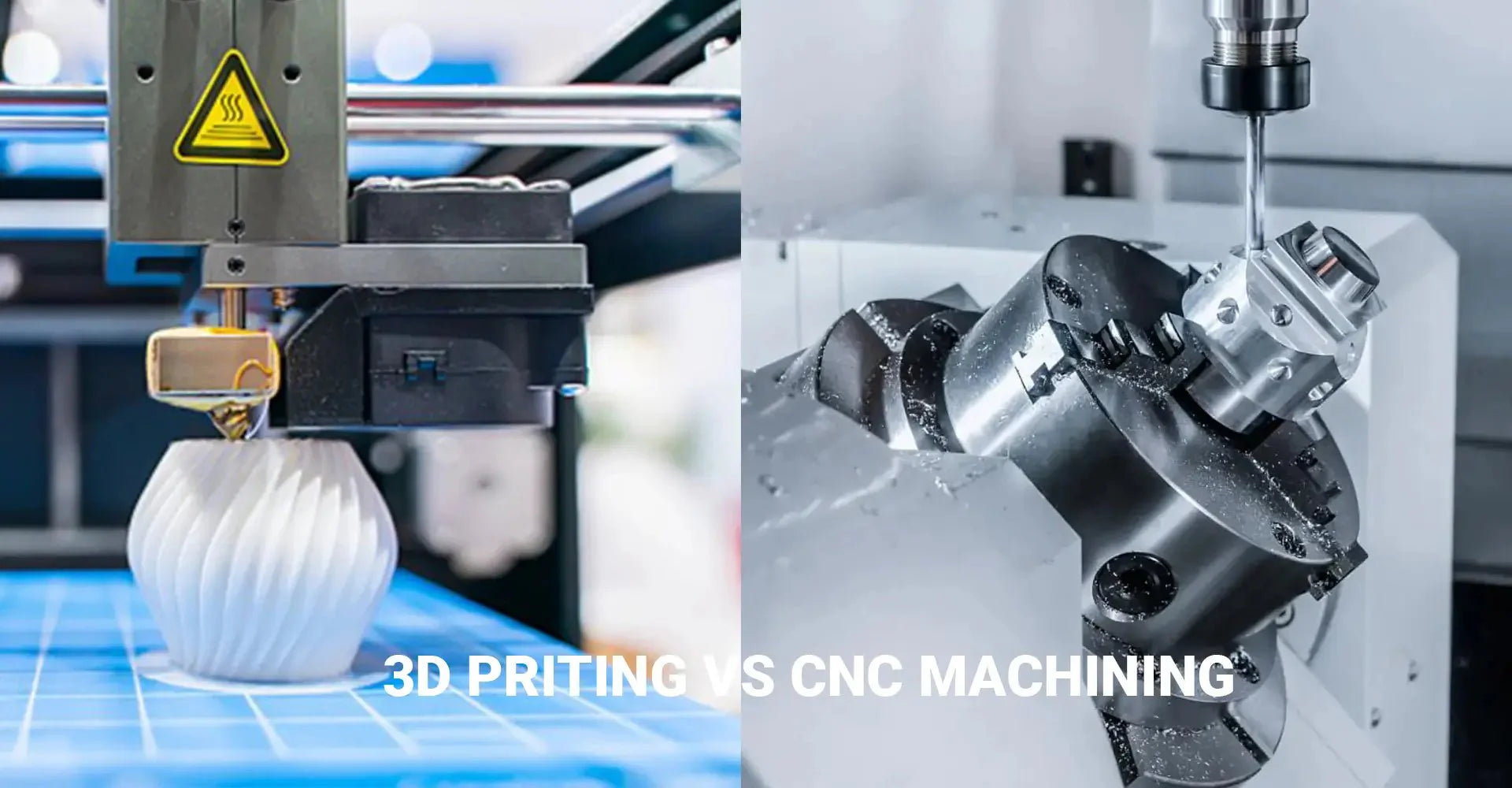

Manufacturing technology has evolved significantly in recent years, presenting businesses with multiple options for producing parts and products. Among these, 3D printing and CNC machining stand out as two dominant technologies, each offering unique advantages and capabilities.

If you're evaluating these technologies for your next project, this comprehensive guide will help you make an informed decision based on your specific needs and requirements. We'll examine everything from cost considerations to precision capabilities, ensuring you have all the information needed to choose the right manufacturing method.

In this detailed comparison, we'll explore how these industrial manufacturing methods stack up against each other in various aspects, including cost-effectiveness, precision, and industry applications.

[Table of Contents]

- What Are The Fundamental Differences Between 3D Printing and CNC Machining?

- How Do These Technologies Compare in Terms of Cost and Efficiency?

- Which Industries Benefit Most from Each Manufacturing Method?

- What Level of Precision Can You Expect from Each Technology?

What Are The Fundamental Differences Between 3D Printing and CNC Machining?

Understanding the basic principles behind these technologies is crucial for making an informed decision. 3D printing, also known as additive manufacturing, builds objects layer by layer from digital models. This process allows for complex geometries that traditional methods might struggle with.

The fundamental distinction lies in their approach to creating parts: while 3D printing adds material layer by layer, CNC machining removes material from a solid block to achieve the desired shape. This difference significantly impacts design possibilities and manufacturing capabilities.

When examining these technologies in detail, we find that each has its unique strengths in different manufacturing scenarios. The choice between them often depends on factors such as production volume, material requirements, and design complexity.

How Do These Technologies Compare in Terms of Cost and Efficiency?

The cost comparison between these technologies reveals interesting insights for project planning and budgeting. Initial investment costs differ significantly, with CNC machining typically requiring higher upfront costs but potentially lower per-part costs at scale.

Key statistics show that 3D printing can be up to 55% cheaper than CNC for certain parts, though production time may be longer. This cost advantage is particularly notable in low-volume production runs and prototyping phases.

For automotive and electronics manufacturing industries, the efficiency metrics become even more crucial when considering large-scale production requirements.

Which Industries Benefit Most from Each Manufacturing Method?

Different industries leverage these technologies based on their specific requirements. The aerospace industry often requires both technologies, with CNC machining preferred for high-stress components and 3D printing for complex, lightweight parts.

In the medical field, 3D printing excels in creating custom implants and prosthetics, while CNC machining is crucial for producing precise surgical instruments. The automotive industry utilizes both technologies, with 3D printing accelerating prototyping and CNC machining handling production parts.

Each industry's unique needs influence the choice between these technologies, with factors like material requirements and production volumes playing crucial roles.

What Level of Precision Can You Expect from Each Technology?

Precision capabilities vary significantly between these technologies. CNC machining achieves impressively tight tolerances of around 0.005mm, making it ideal for high-precision components.

3D printing typically offers tolerances of about 0.2mm, which is suitable for many applications but may not meet the most stringent precision requirements. This difference in precision capabilities often influences the choice of technology for specific applications.

Understanding these precision limitations is crucial for determining which technology best suits your specific project requirements.

Conclusion

The choice between 3D printing and CNC machining ultimately depends on your specific project requirements. Consider factors such as:

- Production volume requirements

- Required precision and tolerance levels

- Budget constraints

- Material specifications

- Time to market needs

For optimal results, many successful projects combine both technologies, leveraging the strengths of each at different stages of production.

[External Links Recommendation]

-

Posted in

3D Printing, CNC machining