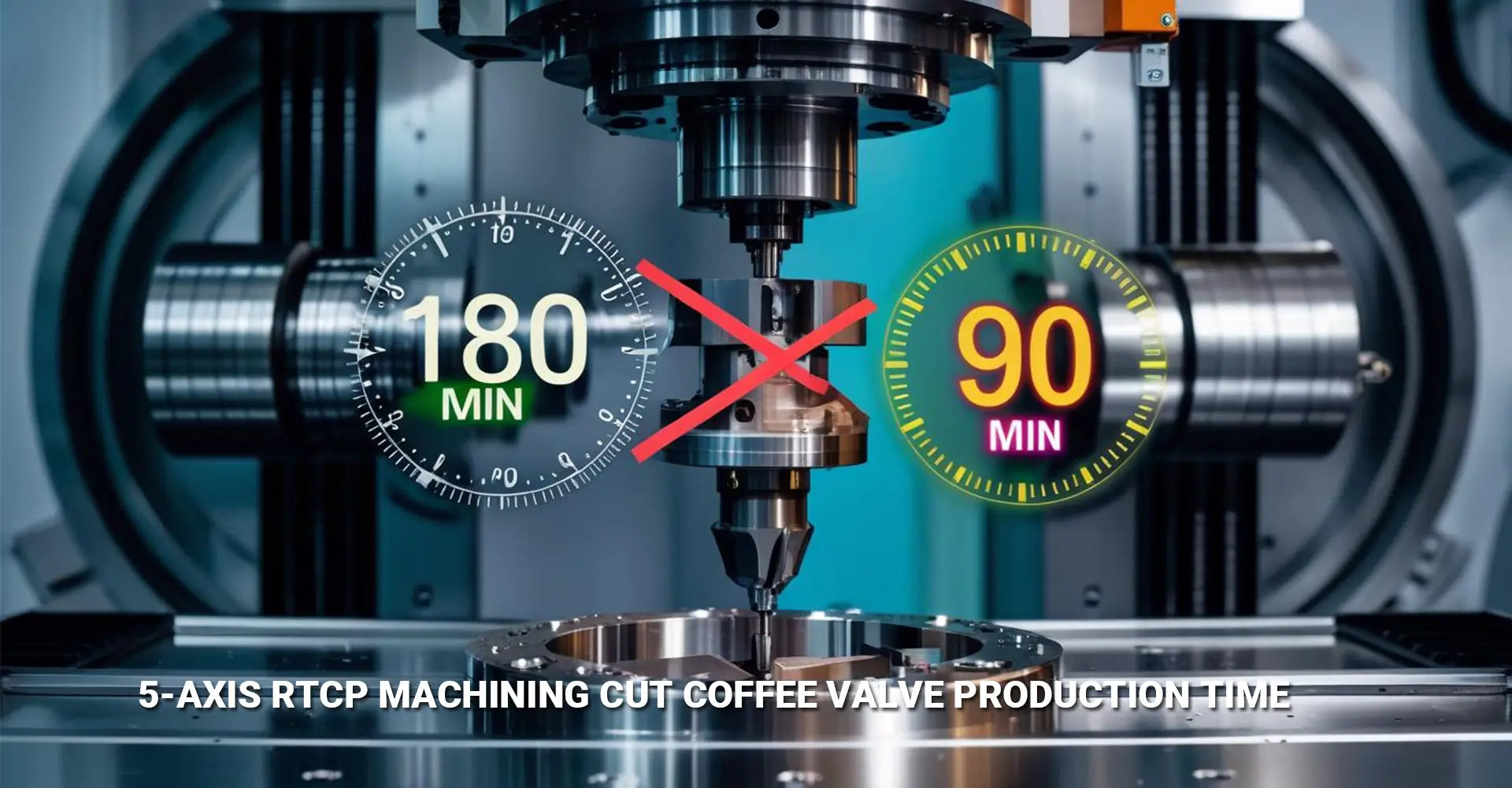

How Does 5-Axis RTCP Machining Cut Coffee Valve Production Time from 180 to 90 Minutes?

How Does 5-Axis RTCP Machining Cut Coffee Valve Production Time from 180 to 90 Minutes?

Coffee valve manufacturers struggle with lengthy production cycles and multiple setups when using traditional 3-axis machining. However, 5-axis RTCP (Rotary Tool Center Point) machining offers a proven solution that reduces cycle time by 50% while improving accuracy by 60%. This comprehensive guide reveals exactly how leading manufacturers achieve these results through advanced CNC machining services.

Key Benefits at a Glance:

- Cycle Time Reduction: From 180 minutes to 90 minutes per valve

- Setup Elimination: Single clamping replaces 3 separate setups

- Accuracy Improvement: ±0.02mm vs ±0.05mm tolerance

- Surface Finish: Achieves Ra 0.4μm in deep channels

- Cost Savings: 73% reduction in setup time

Understanding these dramatic improvements requires examining the specific limitations of traditional 3-axis methods. Moreover, implementing 5-axis RTCP successfully depends on proper postprocessor configuration and programming techniques that directly impact production efficiency.

Table of Contents

- Why Does 3-Axis Machining Waste 65% of Coffee Valve Production Time?

- What Makes RTCP Control Critical for Multi-Passage Valve Manufacturing?

- Which Programming Mistakes Cost Manufacturers Time and Money?

- How Can You Configure Postprocessors for Maximum Cycle Time Reduction?

Why Does 3-Axis Machining Waste 65% of Coffee Valve Production Time?

Traditional 3-axis machining creates significant bottlenecks in coffee valve production due to geometric limitations. Furthermore, complex internal passages require multiple setups that consume valuable production time and compromise part quality.

3-Axis Limitations:

- Multiple Setups Required: 3 separate clamping operations

- Extended Setup Time: 45 minutes between operations

- Tool Access Issues: Cannot reach angled passages directly

- Reduced Accuracy: ±0.05mm tolerance due to repositioning errors

Each setup change introduces positioning errors that accumulate throughout the process. Additionally, 3-axis machines cannot maintain optimal cutting angles when machining curved internal passages. This limitation forces manufacturers to use longer tools that create vibration and reduce surface finish quality. Consequently, cycle times extend significantly while part quality suffers.

The most problematic aspect involves machining intersecting channels that require different approach angles. Therefore, manufacturers must remove the workpiece multiple times, losing valuable reference points. Meanwhile, complex channel machining becomes nearly impossible when passages intersect at acute angles or follow curved paths through the valve body.

What Makes RTCP Control Critical for Multi-Passage Valve Manufacturing?

RTCP (Rotary Tool Center Point) control maintains precise tool positioning during 5-axis simultaneous machining operations. This capability proves essential for coffee equipment components containing multiple intersecting passages that demand precise flow characteristics.

RTCP Benefits:

- Continuous Tool Orientation: Maintains optimal cutting angle

- Single Setup Completion: All features machined in one clamping

- Shorter Tool Usage: Increased rigidity allows 25-30% faster feeds

- Complex Geometry Access: Reaches previously impossible angles

RTCP control calculates tool center point position in real-time as rotary axes move. Therefore, the cutting tool maintains its programmed path regardless of machine axis orientation. This capability enables continuous machining of complex curved channels without repositioning the workpiece. As Reddit user u/PrecisionFlow noted: "We eliminated 2 setups and 3 custom fixtures with 5-axis RTCP control."

The technology becomes particularly valuable when working with premium materials like stainless steel or brass commonly used in high-end coffee machines. Additionally, RTCP machining benefits include consistent chip evacuation throughout the process, preventing heat buildup that could damage delicate internal surfaces. This consistent performance ensures that every valve meets strict flow rate specifications required for proper coffee extraction.

Which Programming Mistakes Cost Manufacturers Time and Money?

Common programming errors in 5-axis coffee valve machining lead to tool crashes, poor surface finish, and extended cycle times. However, these issues are preventable with proper planning and understanding of tool interference avoidance principles.

Critical Programming Errors:

- Incorrect Tool Axis Control: Causes gouging in tight radii

- Excessive Tool Tilt: Creates chip evacuation problems

- Poor Transition Planning: Results in surface quality issues

- Inadequate Collision Checking: Leads to toolholder crashes

The most frequent mistake involves using incorrect tool diameter ratios for passage machining. Specifically, tools exceeding 80% of passage diameter create interference problems that compromise both quality and cycle time. Additionally, tool tilts beyond 45 degrees prevent proper chip evacuation in deep channels, leading to tool breakage and surface defects.

Reddit user u/5AxisWizard reported: "Proper postprocessor configuration prevented tool crashes in deep channels that plagued our DMG Mori NTX." This experience highlights how programming errors often stem from inadequate machine simulation before actual cutting begins.

Another common issue involves transition zones where the tool changes direction between passages. Consequently, sudden direction changes create witness marks and dimensional variations. Therefore, smooth transitions with gradual axis movements prove essential for maintaining consistent CNC metals and plastics processing quality.

How Can You Configure Postprocessors for Maximum Cycle Time Reduction?

Postprocessor configuration directly impacts 5-axis machining success and cycle time reduction results. Proper setup ensures smooth RTCP operation and prevents costly machine crashes during coffee machine part CNC production runs.

Configuration Requirements:

- RTCP Enablement: M128 command for Heidenhain controllers

- Tool Orientation Control: Automatic axis management

- Collision Avoidance: Real-time interference checking

- Smooth Motion: Optimized axis interpolation

Different machine controllers require specific postprocessor configuration 5-axis settings for optimal RTCP performance. For example, Heidenhain TNC640 systems use M128 to enable RTCP mode with automatic tool orientation. Meanwhile, Fanuc controllers employ different G-codes for similar functionality.

Proper configuration also includes setting appropriate acceleration limits and smoothing parameters to prevent axis oscillation during complex interpolated moves. Here's a sample Heidenhain configuration:

# Heidenhain TNC640 RTCP Output

BEGIN TILTING_MODE

M128 ; Enable RTCP

CYCL DEF 247 DATUM SETTING ~

Q339=+1 ; Automatic tool orientation

CYCL DEF 7.0 TILTED WORKING PLANE ~

Q381=+25 ; Tool tilt angle

Additionally, successful multi-passage valve manufacturing requires careful attention to feed rate optimization during axis transitions. Therefore, postprocessors must balance cutting efficiency with surface quality requirements throughout the entire machining cycle.

Conclusion

5-axis RTCP machining transforms coffee valve production by eliminating multiple setups and reducing cycle times by 50%. Success requires understanding 3-axis limitations, implementing proper RTCP control, avoiding common programming mistakes, and configuring postprocessors correctly for consistent results.

Manufacturers who implement these techniques consistently achieve 90-minute cycle times compared to traditional 180-minute processes. Moreover, improved accuracy and surface finish quality justify the investment in 5-axis technology. Start with proper postprocessor configuration, then gradually implement advanced programming techniques for maximum results.

The key lies in recognizing that modern coffee equipment demands precision that only 5-axis simultaneous machining can deliver. Therefore, manufacturers who embrace these technologies will maintain competitive advantages in an increasingly demanding market.

External Links Recommendation:

[5-axis coffee valve machining][^1]

[RTCP machining benefits][^2]

[multi-passage valve manufacturing][^3]

[5-axis simultaneous machining][^4]

[complex channel machining][^5]

[postprocessor configuration 5-axis][^6]

---

[^1]: Discover the unique benefits of 5-axis machining for coffee valves, enhancing precision and efficiency in production.

[^2]: Explore the advantages of RTCP machining, which can significantly improve accuracy and reduce production time.

[^3]: Exploring this resource will provide insights into advanced techniques and innovations in multi-passage valve manufacturing.

[^4]: This link will help you understand the benefits and applications of 5-axis machining in modern manufacturing processes.

[^5]: Understanding complex channel machining can enhance your knowledge of advanced manufacturing techniques and their applications.

[^6]: Learning about postprocessor configuration for 5-axis machining is crucial for optimizing CNC operations and improving precision.