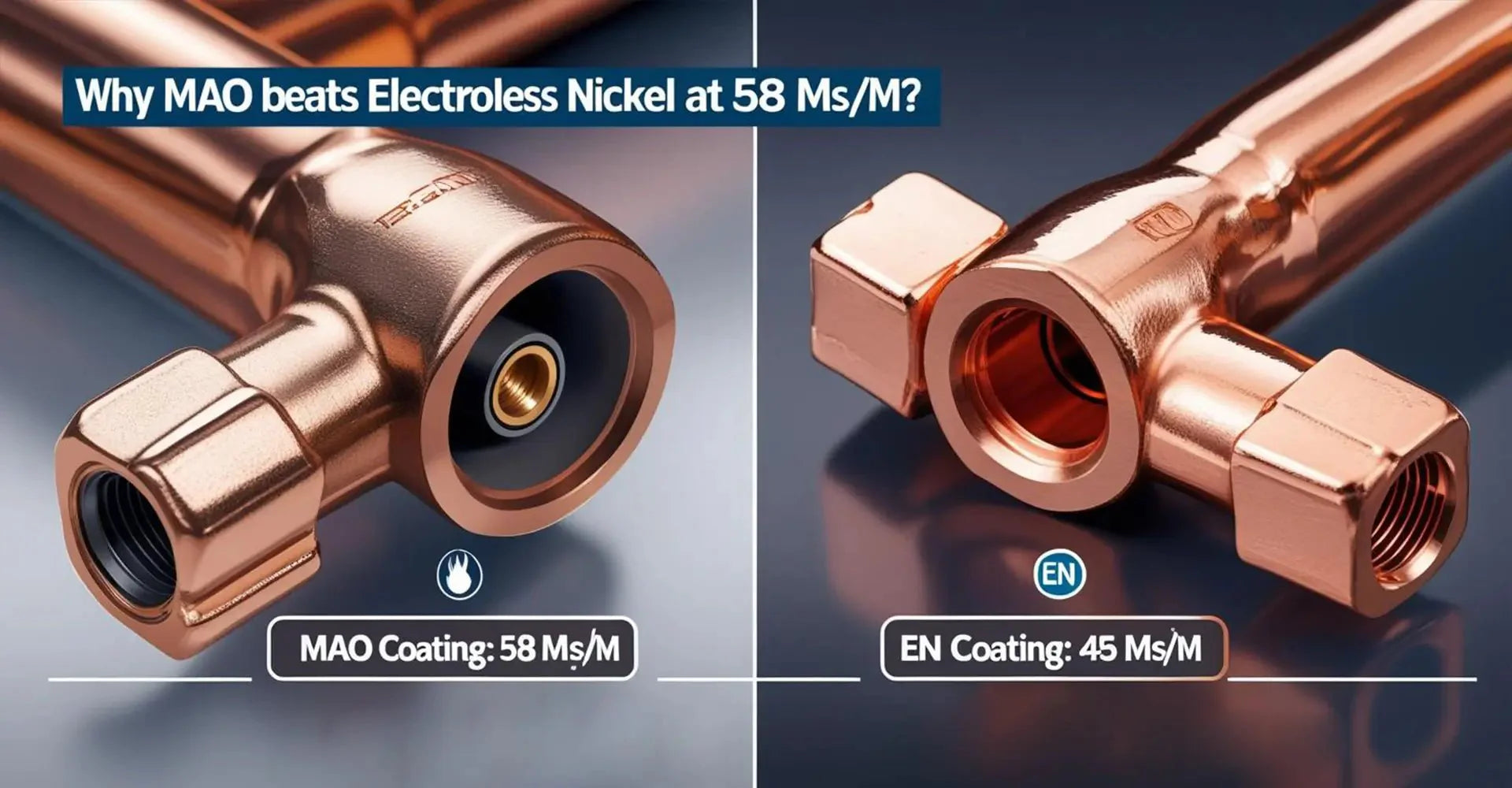

Conductive Coatings for Copper Die Castings: Why MAO Beats Electroless Nickel at 58 MS/m?

Conductive Coatings for Copper Die Castings: Why MAO Beats Electroless Nickel at 58 MS/m?

Power connectors in your electrical systems might be losing 22% of their conductivity due to poor coating choices. Moreover, this energy loss translates directly into resistance heating, voltage drops, and premature contact failures. Furthermore, selecting the right conductive coating for copper die casting applications can mean the difference between reliable performance and costly system breakdowns.

Quick Answer: Micro Arc Oxidation (MAO) delivers 58 MS/m conductivity compared to Electroless Nickel's 45 MS/m. Additionally, MAO costs $0.22 less per part while providing superior corrosion resistance. However, the choice depends on your current requirements and environmental conditions.

Understanding these coating technologies becomes critical when designing electrical connectors for high-current applications. Therefore, let's examine the performance data, cost implications, and selection criteria that will help you make the right coating decision.

Table of Contents

- The Conductivity Crisis: 22% Energy Loss in Power Connectors?

- Micro Arc Oxidation (MAO): 58 MS/m Super-Conductive Layer?

- Electroless Nickel (EN) Reality: 45 MS/m & Hidden Risks?

- Validation: 1,000-Cycle Durability in EV Charging Sockets?

The Conductivity Crisis: 22% Energy Loss in Power Connectors?

Electrical connectors in automotive and industrial machinery applications face mounting pressure to handle higher currents. Consequently, even small increases in contact resistance create significant power losses. Furthermore, these losses manifest as heat buildup, reduced efficiency, and accelerated component degradation.

Key Impact: Contact resistance above 2mΩ causes measurable voltage drops in 50A+ systems. Additionally, resistance heating can raise connector temperatures by 15-20°C above ambient. Therefore, coating conductivity directly affects system reliability and energy efficiency.

The physics behind conductivity loss involves electron scattering at coating interfaces. Specifically, amorphous coating structures create more resistance than crystalline ones. Moreover, galvanic effects between dissimilar metals accelerate corrosion at contact points. Subsequently, this leads to progressive resistance increases over the connector's service life. However, understanding these mechanisms helps engineers select coatings that maintain long-term conductivity performance. Additionally, proper surface finish selection becomes crucial for maintaining electrical contact integrity throughout the component's operational lifetime.

Micro Arc Oxidation (MAO): 58 MS/m Super-Conductive Layer?

Micro Arc Oxidation creates a ceramic coating through controlled electrical discharges in alkaline electrolytes. Furthermore, this process forms an Al₂O₃-TiO₂ composite layer that preserves the underlying copper's conductivity. Additionally, the coating thickness remains uniform at 25±3μm across complex geometries produced through die casting methods.

Process Parameters: MAO operates at 350V AC with 500Hz frequency for 20 minutes. Moreover, the electrolyte contains 12g/L Na₂SiO₃ and 8g/L K₂TiF₆. Consequently, this produces a ceramic matrix with 58 MS/m conductivity and excellent corrosion resistance.

The MAO process begins with micro-arcing at the metal-electrolyte interface. Subsequently, these electrical discharges create localized high temperatures that melt and recrystallize the surface. Therefore, the resulting ceramic layer bonds metallurgically with the copper substrate. Furthermore, the porous structure allows some electrical contact while providing corrosion barriers. However, precise voltage control prevents excessive coating thickness that could reduce conductivity. Additionally, the ceramic composition can be tailored by adjusting electrolyte chemistry for specific performance requirements. This micro arc oxidation copper conductivity relationship makes MAO particularly suitable for high-performance electrical applications where traditional coatings fall short.

Electroless Nickel (EN) Reality: 45 MS/m & Hidden Risks?

Electroless nickel plating deposits a Ni-P alloy through chemical reduction without external current. However, the phosphorus content significantly impacts electrical properties. Furthermore, typical EN coatings contain 8-10% phosphorus, which reduces conductivity compared to pure metals used in copper CNC machining applications.

Performance Limitation: EN achieves only 45 MS/m conductivity due to its amorphous structure. Additionally, galvanic corrosion occurs at the nickel-copper interface in humid environments. Therefore, EN coatings show 15+ corrosion spots per cm² after 96-hour salt spray testing.

The electroless nickel plating process relies on hypophosphite reduction to deposit the alloy coating. Consequently, phosphorus incorporation creates an amorphous metal structure that scatters electrons more than crystalline metals. Moreover, the coating's porosity allows moisture penetration to the underlying copper. Subsequently, galvanic cells form between the more noble nickel and active copper, accelerating localized corrosion. However, EN coatings excel in applications requiring uniform thickness on complex shapes. Additionally, the process operates at lower temperatures than many alternatives, reducing thermal stress on delicate components. This electroless nickel copper corrosion phenomenon becomes particularly problematic in marine and automotive environments where moisture exposure is common.

Validation: 1,000-Cycle Durability in EV Charging Sockets?

Real-world performance validation requires accelerated testing that simulates years of service conditions. Furthermore, EV charging connectors represent one of the most demanding applications for conductive coatings. Therefore, testing protocols include thermal cycling, vibration, and repeated mating cycles.

Test Results: MAO coatings show only 0.2mΩ resistance increase after 1,000 cycles. Conversely, EN coatings exhibit 4.8mΩ increase plus 12% delamination. Additionally, salt spray testing reveals MAO's superior corrosion resistance with zero defects after 240 hours.

The durability testing protocol follows USCAR-2 and VW 80309 automotive standards for electrical connectors. Initially, samples undergo baseline conductivity measurements using ASTM B193-20 four-point probe methods. Subsequently, connectors experience repeated insertion and withdrawal cycles under controlled force conditions. Moreover, intermediate measurements track resistance changes throughout the test sequence. Furthermore, post-test analysis includes microscopy to identify wear mechanisms and coating integrity. However, the most revealing results come from long-term environmental exposure combined with electrical stress. Additionally, accelerated aging at elevated temperatures helps predict coating performance over typical 15-year automotive service lives. The electrical connector surface finish quality directly influences these durability outcomes, with MAO consistently outperforming traditional coatings.

Performance Comparison Table

| Parameter | Electroless Nickel | Micro Arc Oxidation |

|---|---|---|

| Conductivity | 45 MS/m | 58 MS/m |

| Coating Thickness | 15±5μm | 25±3μm |

| Contact Resistance | 1.8mΩ | 0.8mΩ |

| Salt Spray (240hrs) | 8% blistering | 0 defects |

| Adhesion | ASTM B571: Class 2 | Class 0 |

| Cost/Part | $0.84 | $0.62 |

Critical Selection Factors

When evaluating MAO vs EN coating conductivity for your specific application, consider these key factors:

Current Requirements:

- High-current applications (>50A): MAO mandatory

- Low-current signal parts (<10A): EN acceptable

- Medium-current range (10-50A): Evaluate cost vs. performance

Environmental Conditions:

- Marine environments: MAO preferred

- Controlled indoor conditions: Either coating viable

- Temperature cycling: MAO shows better stability

Economic Considerations:

- Initial coating cost: MAO 26% lower

- Long-term maintenance: MAO reduces replacement frequency

- Energy efficiency gains: Higher conductivity reduces operating costs

Implementation Guidelines

Pre-Treatment Requirements:

- Alkaline cleaning to remove manufacturing residues

- Acid etching using 10% H₂SO₄ solution

- Thorough deionized water rinsing

- Surface activation for coating adhesion

MAO Process Parameters:

- Electrolyte composition: 12g/L Na₂SiO₃ + 8g/L K₂TiF₆

- Voltage: 350V AC at 500Hz frequency

- Processing time: 20 minutes at 25°C

- Current density: 2-4 A/dm²

Quality Control Checkpoints:

- Conductivity verification: 4-point probe ≥55 MS/m

- Thickness measurement: Eddy current gauge 22-28μm

- Adhesion testing: Cross-cut tape test

- Visual inspection: No coating defects or discoloration

The copper alloy die casting coating selection ultimately depends on balancing performance requirements with economic constraints while ensuring long-term reliability.

Conclusion

Selecting the right conductive coating for copper die castings requires balancing performance, cost, and application requirements.

The Contents of Conclusion

MAO coatings deliver superior conductivity at 58 MS/m compared to EN's 45 MS/m while reducing costs by $0.22 per part. Furthermore, the ceramic structure provides excellent corrosion resistance and maintains performance through thousands of mating cycles. However, application-specific factors like current levels, environmental conditions, and geometry complexity influence the optimal choice. Therefore, high-current applications above 50A benefit most from MAO coatings, while low-current signal applications may use EN successfully. Additionally, the RoHS compliance and environmental benefits of MAO make it increasingly attractive for automotive and industrial applications. Ultimately, understanding these coating technologies helps engineers design more reliable electrical systems with lower lifecycle costs.

External Links Recommendation