How Does Counter Pressure Casting Reduce Porosity by 70% Compared to Traditional HPDC?

How Does Counter Pressure Casting Reduce Porosity by 70% Compared to Traditional HPDC?

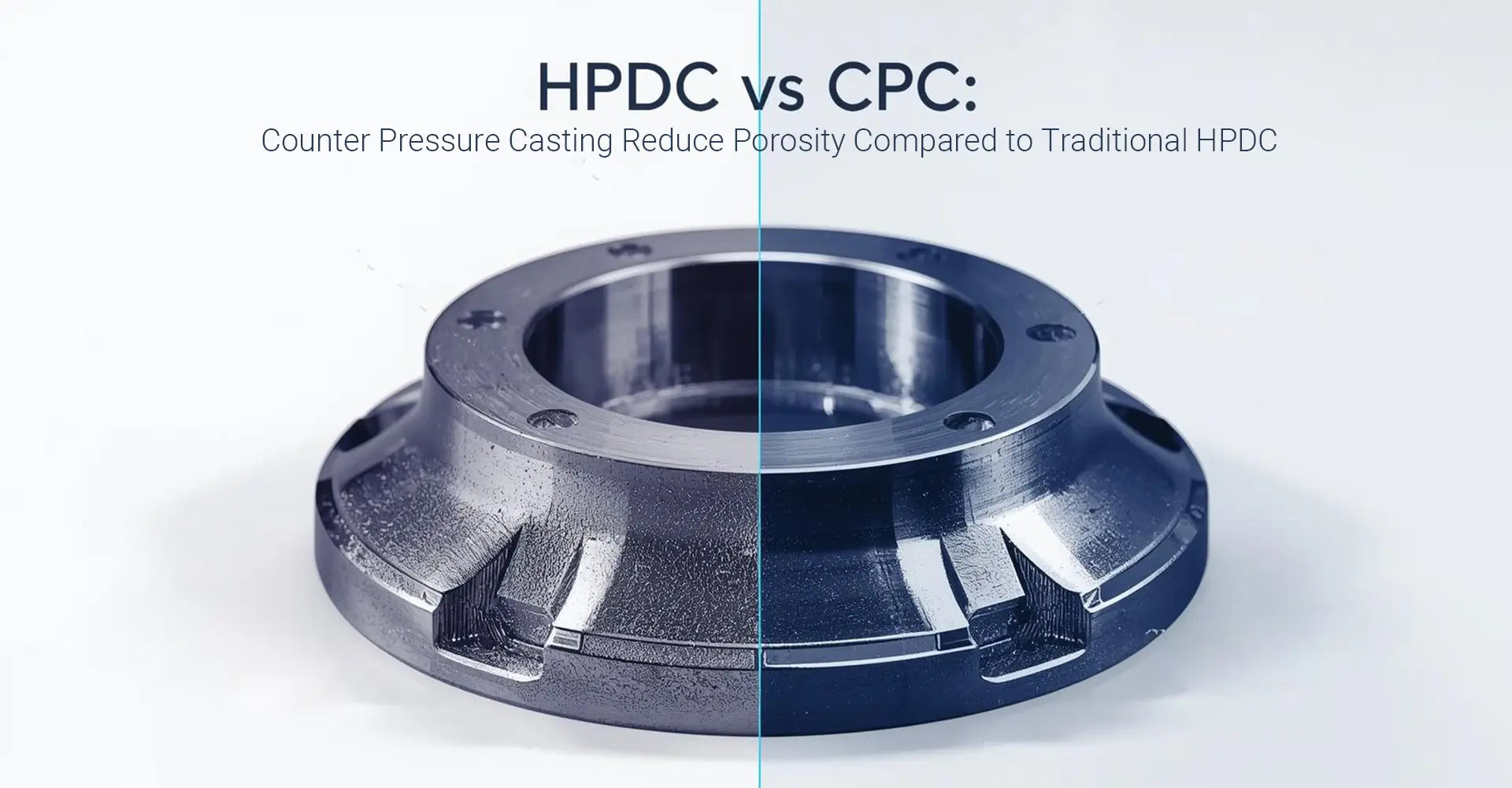

Counter Pressure Casting (CPC) stands as a game-changing die casting method that delivers near-net-shape density and precision. Unlike traditional High-Pressure Die Casting (HPDC), CPC eliminates up to 70% of casting defects through controlled pressure gradients. This advanced casting technique prevents gas entrapment and turbulent flow, resulting in superior part integrity for safety-critical applications.

Quick Facts: CPC vs Traditional HPDC

- Defect Reduction: 70% fewer casting defects

- Gas Porosity: Reduced from 15% to 2%

- Scrap Rate: Drops from 12% to 3%

- Applications: Automotive, aerospace, hydraulic components

- Key Benefit: Heat-treatable and weldable parts

While traditional die casting serves many industries well, manufacturers seeking premium quality parts face significant challenges. Gas porosity, shrinkage defects, and poor mechanical properties limit component applications. However, Counter Pressure Casting addresses these issues through innovative pressure control technology.

Table of Contents

- What Makes Counter Pressure Casting Different from Standard Die Casting?

- Why Does CPC Achieve 70% Better Defect Rates Than HPDC?

- How Does the CPC Process Work Step-by-Step?

- Which Applications Benefit Most from Counter Pressure Casting?

What Makes Counter Pressure Casting Different from Standard Die Casting?

Traditional High-Pressure Die Casting forces molten metal into molds at extremely high velocities. This rapid injection creates turbulent flow patterns that trap air, lubricant vapors, and other gases within the casting. Consequently, parts suffer from internal porosity that weakens mechanical properties and prevents post-casting treatments like those offered by advanced die casting services.

CPC Process Advantages:

- Laminar Flow: Smooth metal filling vs. turbulent HPDC injection

- Pressure Control: Pre-pressurized cavity eliminates gas entrapment

- Vacuum Stage: Complete air removal before metal injection

- Enhanced Density: Near-theoretical material density achieved

Counter Pressure Casting reverses the traditional approach by first creating a controlled environment within the die cavity. The process begins with hermetic sealing, followed by vacuum evacuation to remove all air. Subsequently, an inert gas pressurizes the cavity above the metal injection pressure. This pressure differential ensures that molten metal flows smoothly and completely fills even complex geometries without creating voids or gas pockets. The CPC die casting process represents a significant advancement in achieving pore-free die casting through precise control parameters.

Why Does CPC Achieve 70% Better Defect Rates Than HPDC?

Industry data consistently shows that Counter Pressure Casting dramatically outperforms traditional methods in defect reduction. The controlled filling process eliminates the primary causes of casting defects: gas entrapment, turbulent flow, and incomplete cavity filling. These improvements translate directly into measurable quality improvements that exceed standard die casting consistency requirements.

Defect Comparison Data:

- Gas Porosity: HPDC 15% → CPC 2% (87% reduction)

- Shrinkage Porosity: HPDC 10% → CPC 4% (60% reduction)

- Overall Scrap Rate: HPDC 12% → CPC 3% (75% reduction)

- Surface Quality: Significantly improved cosmetic appearance

The dramatic defect reduction stems from CPC's ability to control metal flow dynamics and achieve superior Casting Process Capability CPC standards. Traditional HPDC injection speeds often exceed 3-4 m/s, creating Reynolds numbers that guarantee turbulent flow. In contrast, CPC maintains low turbulence filling conditions throughout the filling process. Additionally, the pre-pressurized cavity prevents gas dissolution and subsequent porosity formation during solidification. This controlled environment also enables better directional solidification, further reducing shrinkage-related defects. The result is reduced porosity casting that meets the highest industry standards for structural applications.

How Does the CPC Process Work Step-by-Step?

Understanding the Counter Pressure Casting process requires examining each carefully orchestrated step. Unlike conventional die casting's single injection phase, CPC involves multiple stages that work together to create superior part quality. Each step serves a specific purpose in eliminating defects and achieving dense castings with density improvement die casting technology.

CPC Process Steps:

- Die Sealing: Hermetic closure prevents gas leakage

- Evacuation: Vacuum removes all cavity air

- Pressurization: Inert gas fills cavity under pressure

- Injection: Molten metal enters against counter-pressure

- Solidification: Isostatic pressure maintains density

- Ejection: Controlled decompression and part removal

The CPC process begins with die closing and hermetic sealing using specialized gaskets and clamping systems. Next, powerful vacuum pumps evacuate the cavity to pressures below 100 mbar, removing virtually all air and moisture. An inert gas (typically nitrogen) then pressurizes the cavity to 2-5 bar above atmospheric pressure. During injection, molten metal encounters this counter-pressure, which regulates flow velocity and prevents turbulence. As the cavity fills, pressure equalizes, and the metal solidifies under sustained isostatic pressure. Finally, controlled decompression allows safe part ejection without thermal shock. This counter pressure mold technology ensures consistent part quality across production runs.

Which Applications Benefit Most from Counter Pressure Casting?

Counter Pressure Casting excels in applications where part integrity takes priority over production speed. Safety-critical components, structural parts, and components requiring post-casting treatments represent ideal CPC candidates. The technology particularly benefits industries with stringent quality requirements and zero-defect tolerances, often requiring subsequent precision CNC machining services for final specifications.

Prime CPC Applications:

- Automotive Structural: Suspension arms, steering knuckles, crash components

- Hydraulic Systems: Valve bodies, pump housings, pressure vessels

- Aerospace Components: Lightweight structural parts, engine components

- Heat-Treatable Parts: Components requiring T6 temper treatment

- Weldable Castings: Parts needing subsequent joining operations

Automotive applications represent the largest CPC market segment, particularly for aluminum suspension components that undergo significant stress loads. These parts benefit from CPC's enhanced mechanical properties and fatigue resistance through high integrity casting methods. Hydraulic applications leverage CPC's ability to create leak-proof castings without internal porosity that could cause pressure loss. Aerospace components utilize CPC's weight-to-strength advantages, while the defense industry values the technology for mission-critical parts where failure isn't acceptable.

The ability to heat-treat and weld CPC parts expands design possibilities significantly compared to traditional HPDC limitations. Many CPC components benefit from specialized surface finishing processes to achieve final specifications. For applications requiring extreme precision and complex geometries, manufacturers often combine CPC with investment casting techniques to achieve optimal results.

Conclusion

Counter Pressure Casting represents a proven solution for manufacturers seeking superior casting quality over traditional High-Pressure Die Casting methods. With demonstrated 70% defect reduction, CPC technology enables production of structural components, pressure-tight housings, and heat-treatable parts previously impossible with conventional methods. While initial investment costs run higher than standard HPDC, the return on investment comes through reduced scrap rates, elimination of secondary operations, and ability to produce high-value components. For manufacturers prioritizing part integrity, mechanical properties, and zero-defect requirements, Counter Pressure Casting delivers measurable quality improvements that justify the technology investment.

[External Links Recommendation]

[counter pressure casting][^1]

[pore-free die casting][^2]

[high integrity casting][^3]

[counter pressure mold technology][^4]

[reduced porosity casting][^5]

[Casting Process Capability CPC][^6]

------

[^1]: Explore this link to understand how counter pressure casting enhances quality and reduces defects in metal casting.

[^2]: Discover the advantages of pore-free die casting for achieving superior surface finish and structural integrity in cast products.

[^3]: Explore this link to understand how high integrity casting enhances product quality and reduces defects.

[^4]: Discover the advantages of counter pressure mold technology for achieving precision and efficiency in casting.

[^5]: Explore this link to understand how reduced porosity casting enhances product quality and reduces defects.

[^6]: Learn about CPC to improve your casting processes and ensure high-quality production standards.