What Are The Game-Changing Innovations in CNC Milling Technology That Could Revolutionize Your Manufacturing Process?

What Are The Game-Changing Innovations in CNC Milling Technology That Could Revolutionize Your Manufacturing Process?

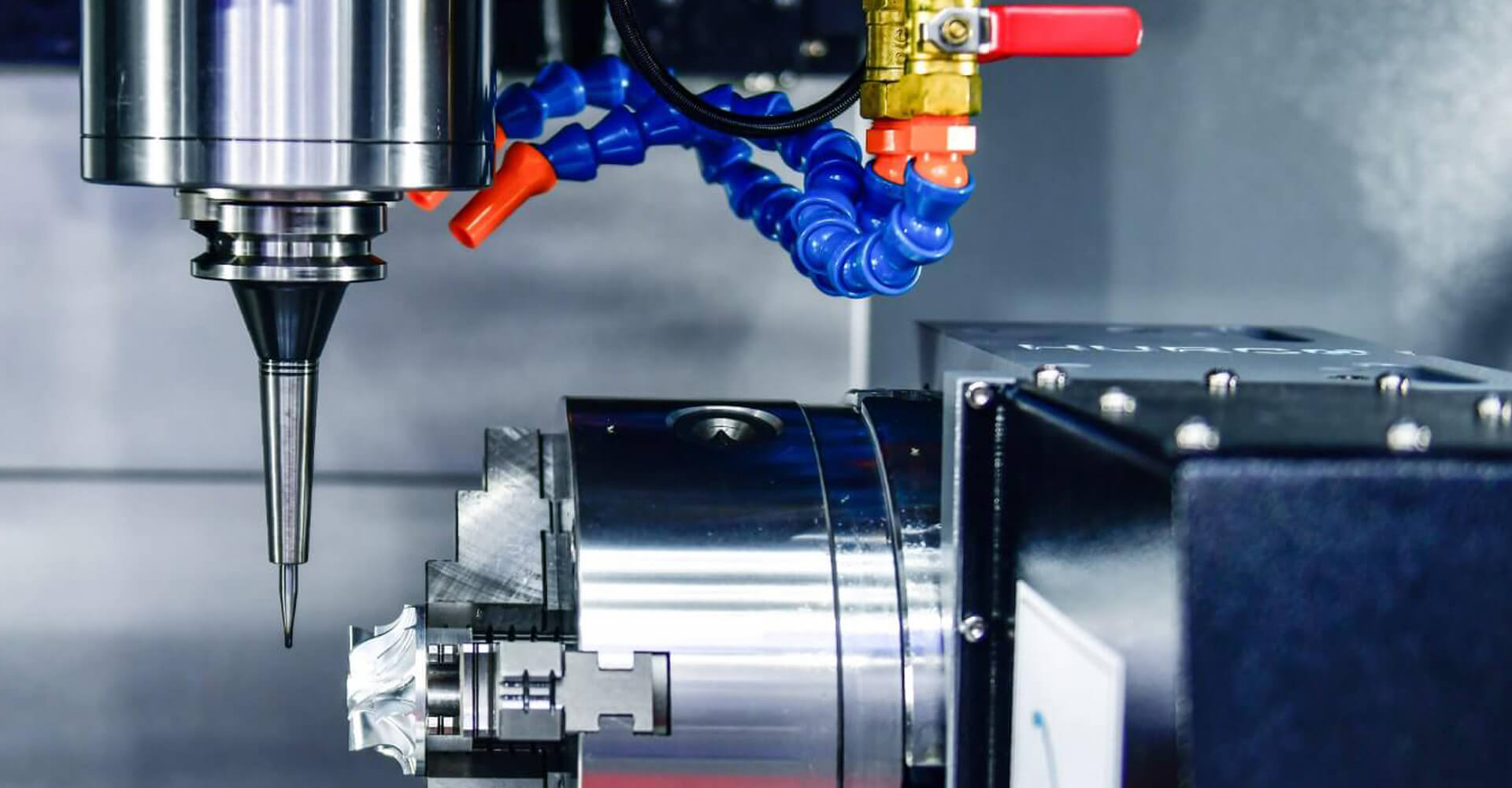

In today's rapidly evolving manufacturing landscape, CNC milling stands as a cornerstone of modern production capabilities. This revolutionary technology has transformed how we approach precision manufacturing, offering unprecedented accuracy, efficiency, and versatility that was unimaginable just decades ago. As we witness the dawn of Industry 4.0, understanding the power of CNC milling becomes crucial for staying competitive in the global market.

From industrial machinery components to medical devices, CNC milling has become indispensable in producing complex parts with microscopic precision. Whether you're a manufacturing veteran or new to the industry, grasping the full potential of this technology could be the key to unlocking new business opportunities and operational efficiencies.

Let's dive deep into the world of CNC milling, exploring everything from its fundamental principles to cutting-edge applications that are reshaping industrial manufacturing. This comprehensive guide will help you understand how CNC milling can transform your production processes and give you a competitive edge in today's market.

[Table Of Content]

- What Exactly is CNC Milling and How Has it Evolved?

- How Do Different Types of CNC Milling Machines Compare?

- Which Materials and Processes Define Modern CNC Milling?

- What Makes CNC Milling Essential in Today's Industries?

What Exactly is CNC Milling and How Has it Evolved?

CNC milling represents the perfect marriage between traditional machining principles and modern computer control systems. This technology has evolved from basic automated machines to sophisticated manufacturing centers capable of producing incredibly complex parts with minimal human intervention.

At its core, CNC milling is a subtractive manufacturing process where computer-controlled cutting tools remove material from a workpiece to create precise components. The journey from manual milling to modern industrial machinery showcases remarkable technological advancement in manufacturing precision and efficiency.

Today's CNC milling machines integrate advanced software, precise motion control systems, and sophisticated cutting tools to achieve accuracies down to microns. This evolution has made it possible to produce components with increasingly complex geometries while maintaining consistent quality across large production runs.

How Do Different Types of CNC Milling Machines Compare?

The world of CNC milling machines is diverse, with each type designed to excel in specific applications. Understanding the distinctions between various configurations is crucial for selecting the right equipment for your manufacturing needs.

From versatile vertical machines for general-purpose work to specialized 5-axis systems for complex automotive components, each type of CNC mill offers unique advantages and capabilities that cater to different manufacturing requirements.

When choosing between different CNC milling configurations, factors such as workspace requirements, part complexity, production volume, and budget all play crucial roles in the decision-making process. Advanced features like automatic tool changers and integrated measurement systems can significantly impact productivity and precision.

Which Materials and Processes Define Modern CNC Milling?

The versatility of CNC milling is perhaps best demonstrated through its ability to work with a vast array of materials, from soft plastics to hardened steels. This flexibility, combined with various cutting strategies, opens up countless possibilities in manufacturing.

Modern CNC milling excels in processing materials for electronics manufacturing, creating everything from aluminum heat sinks to complex circuit board substrates. The key lies in understanding how different materials interact with various cutting tools and processing parameters.

Dive Deeper Paragraph: Success in CNC milling relies heavily on selecting the right combination of cutting tools, speeds, and feeds for each material. Advanced processes like high-speed machining and minimum quantity lubrication have further expanded the capabilities of modern CNC milling operations.

What Makes CNC Milling Essential in Today's Industries?

In today's competitive manufacturing landscape, CNC milling has become indispensable across numerous industries, from aerospace to medical device manufacturing. Its ability to produce complex parts with high precision and repeatability makes it a cornerstone of modern production.

The integration of CNC milling into smart manufacturing systems has revolutionized how industries approach production, enabling everything from rapid prototyping to high-volume manufacturing of precision components.

Looking ahead, the future of CNC milling is being shaped by developments in artificial intelligence, machine learning, and Internet of Things (IoT) integration. These advances promise even greater levels of automation, precision, and efficiency in manufacturing operations.

Conclusion: The Transformative Power of CNC Milling

CNC milling technology continues to evolve and reshape manufacturing capabilities across industries. Whether you're producing complex automotive components, precision electronic parts, or industrial machinery, understanding and leveraging CNC milling technology is crucial for maintaining competitiveness in today's market. As we look to the future, the integration of smart manufacturing technologies promises to make CNC milling even more powerful and accessible.

[External Links Recommendation]