What Ra Value Should You Target for CNC Milling Surface Finish?

What Ra Value Should You Target for CNC Milling Surface Finish?

Understanding CNC surface finish can save you thousands of dollars in machining costs. Many shops chase mirror-like finishes when standard Ra values work perfectly fine. This guide shows you exactly which Ra value to choose for your parts, backed by real machining data from industry professionals.

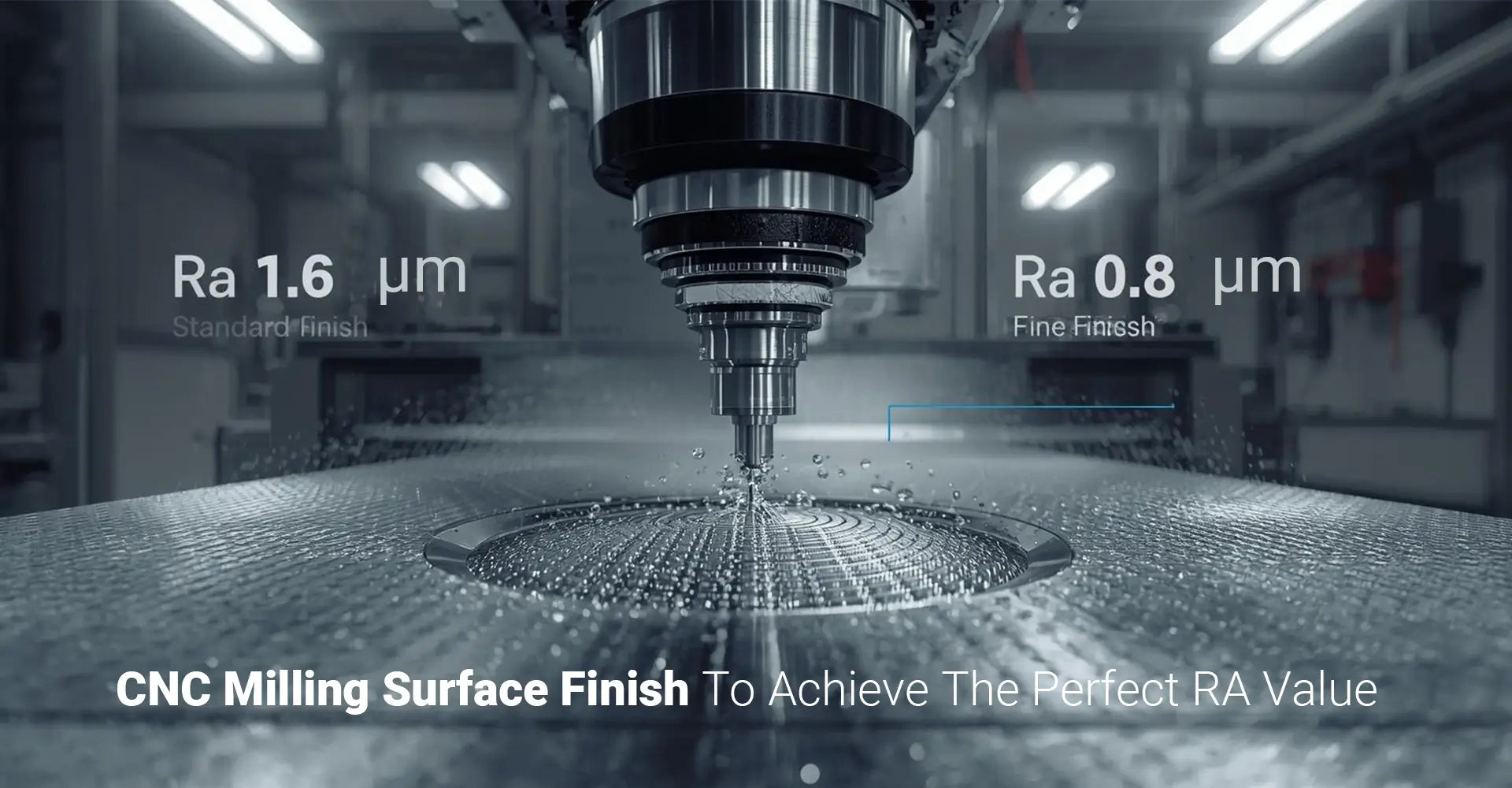

Quick Answer: For most commercial CNC parts, Ra 1.6-3.2 μm (63-125 μin) provides the perfect balance of cost and function. Going from Ra 3.2 to Ra 0.8 typically increases machining costs by 200-400% due to additional finishing passes and specialized tooling requirements.

However, selecting the right surface finish involves more than just picking a number. Different materials, applications, and machining parameters all play crucial roles in achieving your target Ra value cost-effectively.

Table of Contents

- What Ra Values Work Best for Different CNC Applications?

- How Do Machining Parameters Affect Your Surface Finish?

- Which Materials Give You the Smoothest CNC Surface Finish?

- What's the Real Cost of Achieving Different Ra Values?

What Ra Values Work Best for Different CNC Applications?

Choosing the wrong Ra value wastes time and money. Most machinists either over-specify surface finish requirements or settle for rougher finishes than needed. The key lies in matching your Ra value to the actual function of your part.

Standard Ra Ranges by Application:

- Rough machining: Ra 3.2-6.3 μm - for non-critical surfaces

- Standard finish: Ra 1.6-3.2 μm - for most functional parts

- Fine finish: Ra 0.8-1.6 μm - for bearing surfaces

- Very fine finish: Ra 0.4-0.8 μm - for sealing surfaces

The 80/20 rule applies perfectly to surface finish selection. According to industry data, 80% of CNC components perform perfectly with Ra 1.6 finish. This provides adequate function for most mechanical parts without the exponential cost increase of finer finishes. Furthermore, bearing seats typically require Ra 0.8-1.6, while hydraulic sealing surfaces need Ra 0.4-0.8. Meanwhile, structural components often work fine with Ra 3.2-6.3, especially when painted or powder-coated. Therefore, understanding the recommended Ra value for CNC machined parts helps you avoid overengineering surface requirements. Additionally, many custom CNC milling services follow these industry standards to deliver cost-effective solutions.

How Do Machining Parameters Affect Your Surface Finish?

Your machining parameters directly control surface finish quality. Small changes in stepover, feed rate, and spindle speed can dramatically improve or worsen your Ra values. Understanding these relationships helps you hit your target finish without trial and error.

Most Impactful Parameters (in order):

- Reduce stepover to 5-10% of tool diameter for finishing

- Increase cutting speed within tool/material limits

- Use climb milling rather than conventional milling

- Apply adequate coolant for temperature control

Stepover percentage has the most direct impact on surface finish. Consequently, reducing stepover from 25% to 5% of tool diameter typically improves Ra from 3.2 μm to 0.8 μm. However, this also triples machining time. Additionally, feed rate affects finish quality less dramatically but still matters. Higher spindle speeds generally improve finish by reducing built-up edge formation. Moreover, climb milling consistently produces better finishes than conventional milling because the tool cuts cleanly rather than tearing material. When you need to know how to improve CNC milling surface finish, these parameter adjustments deliver the most significant results. Professional CNC machining service providers use these techniques to achieve consistent quality across different materials.

Which Materials Give You the Smoothest CNC Surface Finish?

Different materials behave completely differently under the same machining parameters. Aluminum machines beautifully but builds up on tools. Stainless steel work-hardens if you're not careful. Understanding material-specific challenges prevents surface finish problems before they start.

Material Ranking (easiest to hardest for good finish):

- Aluminum 6061: Can achieve Ra 0.4-0.8 μm easily

- Carbon Steel: Achieves Ra 0.8-1.6 μm with proper parameters

- Stainless Steel 304: Requires sharp tools, achieves Ra 0.8-1.6 μm

- Plastics: Prone to tearing, typically Ra 1.6-3.2 μm

Aluminum offers the best surface finish potential but creates challenges with built-up edge. Using sharp 3-flute carbide end mills with proper chip evacuation prevents aluminum from welding to the tool. Furthermore, stainless steel demands consistent cutting conditions to prevent work hardening - once the surface hardens, achieving good finish becomes nearly impossible. Carbon steel machines predictably with coated carbide tooling. Additionally, plastics require positive rake angles and sharp tools to prevent material tearing rather than clean cutting. The comparison of CNC surface finish for aluminum vs steel shows aluminum typically achieves 2-3 times better Ra values under similar conditions. Professional surface finish services understand these material-specific requirements and adjust parameters accordingly. Various CNC metals plastics require different approaches to achieve target surface quality.

What's the Real Cost of Achieving Different Ra Values?

Surface finish costs increase exponentially, not linearly. Many shops don't realize that improving from Ra 1.6 to Ra 0.8 can double their machining time. Understanding these cost relationships helps you quote accurately and avoid losing money on tight-tolerance jobs.

Cost Increase by Ra Improvement:

- Ra 3.2 to Ra 1.6: +50% machining time

- Ra 1.6 to Ra 0.8: +100% machining time

- Ra 0.8 to Ra 0.4: +150% machining time

- Additional costs: specialized tooling, more tool changes, quality inspection

The exponential cost increase comes from multiple factors working together. Finer finishes require slower feed rates, reduced stepover, and additional finishing passes. Tool wear increases significantly with the extra machining time. Additionally, quality inspection becomes more critical and time-consuming. According to machining professionals, each halving of Ra value approximately doubles total machining time when you factor in setup, tool changes, and inspection requirements. Understanding Ra value tolerance in CNC milling helps manufacturers balance quality requirements with production costs. Moreover, surface roughness optimization involves finding the sweet spot between part function and manufacturing efficiency. Many industrial machinery applications benefit from understanding these cost-quality trade-offs.

Additional Reference Information

CNC Machining Surface Finish Chart:

| Operation | Typical Ra Value | Application Example |

|---|---|---|

| Rough Milling | 6.3-12.5 μm | Non-visible structural components |

| Standard Milling | 3.2-6.3 μm | Machine frames, brackets |

| Finish Milling | 1.6-3.2 μm | General mechanical parts |

| Fine Finish Milling | 0.8-1.6 μm | Bearing seats, sliding surfaces |

| Very Fine Finish | 0.4-0.8 μm | Hydraulic seals, optical mounts |

| Polishing Required | <0.4 μm | Mirror finishes, medical devices |

Machining Ra Value Chart for Different Materials:

| Material | Recommended Tool | Feed Rate | Speed | Achievable Ra |

|---|---|---|---|---|

| Aluminum 6061 | 3-flute carbide end mill | 0.05-0.15 mm/tooth | 200-300 m/min | 0.4-0.8 μm |

| Stainless 304 | 4-5 flute carbide end mill | 0.03-0.08 mm/tooth | 80-120 m/min | 0.8-1.6 μm |

| Carbon Steel | Coated carbide end mill | 0.05-0.12 mm/tooth | 100-180 m/min | 0.8-1.6 μm |

| Plastics | Sharp 2-flute HSS end mill | 0.10-0.20 mm/tooth | 150-250 m/min | 1.6-3.2 μm |

CNC Surface Roughness Standards vary by industry:

- Automotive: Ra 1.6-3.2 μm for most components

- Aerospace: Ra 0.8-1.6 μm for critical parts

- Medical: Ra 0.4-0.8 μm for implantable devices

- General Manufacturing: Ra 3.2-6.3 μm for structural components

Conclusion

Selecting the right Ra value CNC specifications for your parts balances function with cost. Most applications work perfectly with Ra 1.6-3.2 μm standard finishes. Reserve finer finishes for critical applications like bearing surfaces or sealing components. Remember that surface finish costs increase exponentially - improving from Ra 1.6 to Ra 0.8 typically doubles your machining time and costs.

Start by understanding your part's actual functional requirements. Then match your machining parameters to your target Ra value using the guidelines in this article. Finally, consider material-specific challenges when planning your machining strategy. The CNC milling surface finish you choose should always serve the part's intended function rather than arbitrary specifications.

External Links Recommendation

[CNC milling surface finish][^1]

[Ra value CNC][^2]

[CNC surface roughness standards][^3]

[surface roughness optimization][^4]

---

[^1]: Understanding CNC milling surface finish is crucial for achieving high-quality machining results. Explore this link to learn more.

[^2]: The Ra value is essential for determining surface roughness in CNC machining. Discover its significance and applications by following this link.

[^3]: Understanding CNC surface roughness standards is crucial for achieving desired finishes in manufacturing processes.

[^4]: Exploring surface roughness optimization techniques can significantly enhance product quality and performance in manufacturing.