How Does RTCP Die Casting Fixture Cut Setup Time by 70% with Automatic Compensation?

How Does RTCP Die Casting Fixture Cut Setup Time by 70% with Automatic Compensation?

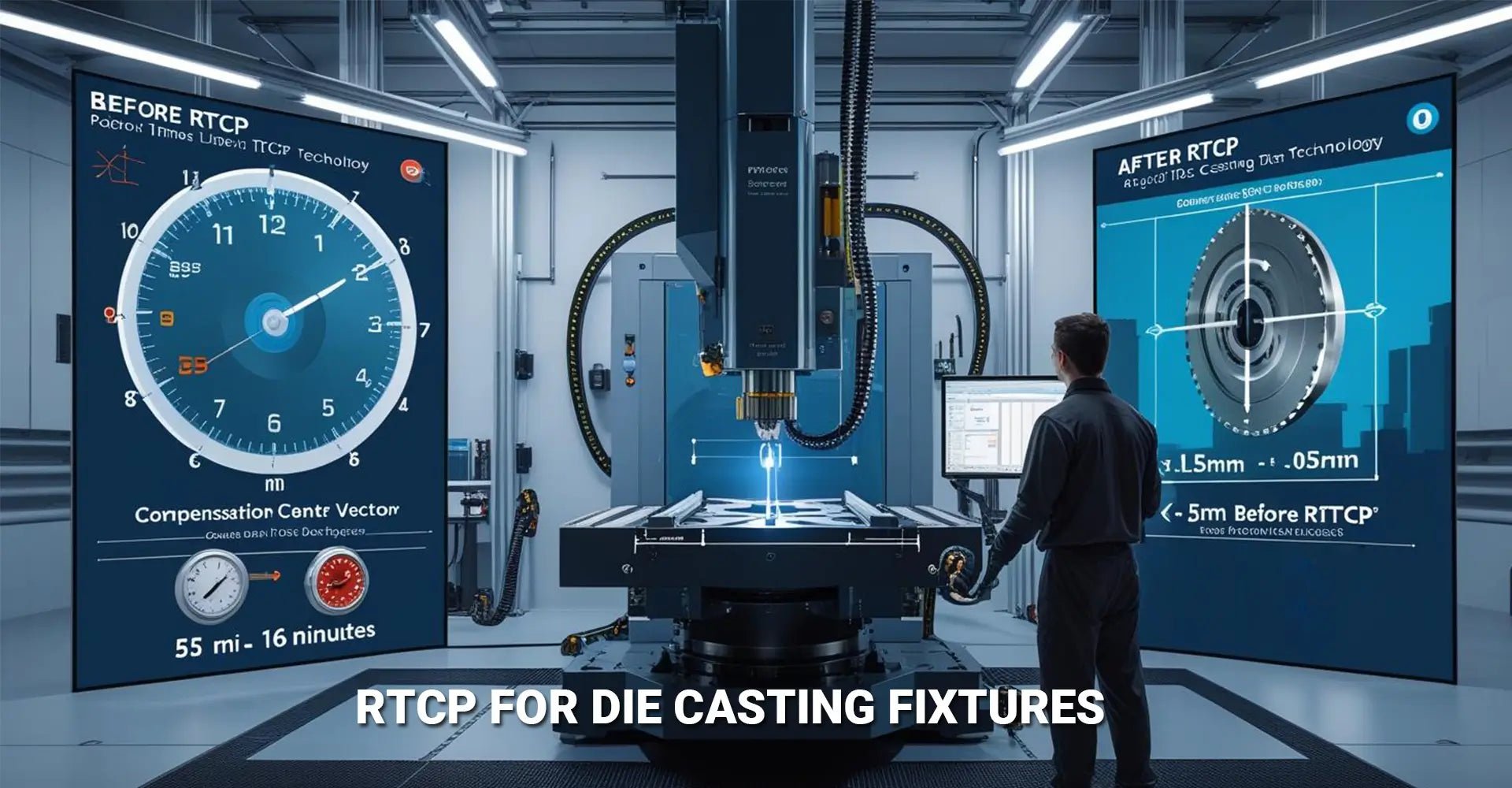

Die casting fixtures have plagued manufacturers for decades with time-consuming setup procedures. However, RTCP (Rotary Tool Center Point) technology changes everything. This advanced compensation system automatically adjusts for casting variations within ±1.5mm tolerance. Moreover, it eliminates manual shimming while maintaining ±0.05mm accuracy. As a result, setup times drop from 55 minutes to just 16 minutes per part.

Key Benefits of RTCP Die Casting Fixture:

- Setup Time Reduction: 70% faster than traditional methods

- Compensation Range: ±1.5mm automatic adjustment

- Accuracy Maintained: ±0.05mm positional tolerance

- Cost Savings: $87.45 per setup cycle

- Probe Cycle Time: 18 seconds for complete mapping

- Surface Finish: Ra 1.6μm on AZ91D magnesium housings

Understanding RTCP die casting fixture technology requires examining both the technical mechanisms and practical applications. Furthermore, manufacturers need clear implementation guidelines to maximize their investment. Therefore, this comprehensive guide covers everything from basic principles to advanced troubleshooting techniques.

Table of Contents

- What Makes Traditional Die Casting Fixturing So Time-Consuming?

- How Does RTCP Compensation Work in Real-Time?

- Can RTCP Handle Warped and Distorted Castings?

- What Accuracy Can You Expect After RTCP Compensation?

What Makes Traditional Die Casting Fixturing So Time-Consuming?

Traditional die casting fixturing creates significant bottlenecks in manufacturing processes. Additionally, casting variations force operators to spend hours on manual adjustments. Consequently, these delays impact overall production efficiency and profitability.

Time-Consuming Traditional Methods:

- Manual shimming takes 35-45 minutes per setup

- Probe cycles require multiple iterations

- Operator skill dependency creates inconsistencies

- Fixture wear increases over time

- Rework rates climb due to positioning errors

Traditional fixturing methods rely heavily on mechanical adjustments and operator expertise. Furthermore, each casting brings unique dimensional variations that require individual compensation. Meanwhile, shim stacks often become unstable under machining forces, leading to accuracy problems. Additionally, the iterative nature of manual setup creates cumulative errors that compound throughout the production run.

When working with die casting components, manufacturers frequently experience quality issues alongside productivity losses. Therefore, the automotive industry has been particularly affected by these challenges. Moreover, die casting part localization becomes nearly impossible without proper fixturing solutions. Consequently, many companies struggle to meet tight delivery schedules while maintaining quality standards.

How Does RTCP Compensation Work in Real-Time?

RTCP compensation uses advanced kinematic calculations to adjust tool paths automatically. Moreover, this technology processes probe data within milliseconds to determine optimal corrections. Consequently, the system compensates for casting variations without stopping the machining process.

RTCP Compensation Process:

- 4-point probing cycle completes in 18 seconds

- Kinematic calculations determine deviation vectors

- Real-time axis recalculation during machining

- Automatic G-code path adjustment

- Continuous compensation throughout the cycle

RTCP compensation operates through sophisticated mathematical algorithms that continuously calculate tool center point positions. Furthermore, the system monitors all five axes simultaneously to maintain precise tool orientation relative to the workpiece. Meanwhile, probe data creates a virtual coordinate system that accounts for casting irregularities. Additionally, the CNC control automatically adjusts linear and rotary axes to maintain programmed tool paths.

The 5-axis RTCP compensation system integrates seamlessly with modern CNC machining services to deliver superior results. Therefore, machining proceeds smoothly regardless of casting variations within the compensation range. Moreover, this technology enables manufacturers to process complex geometries that would otherwise require multiple setups. Consequently, overall cycle times decrease significantly while maintaining dimensional accuracy.

Can RTCP Handle Warped and Distorted Castings?

Warped castings present unique challenges that traditional fixturing cannot address effectively. However, RTCP systems can compensate for specific types of distortion within defined limits. Consequently, manufacturers can process castings that would otherwise require extensive rework or rejection.

RTCP Distortion Compensation Capabilities:

- Bow compensation up to ±1.5mm deviation

- Twist compensation within 3° angular limits

- Multi-point probing for complex geometries

- Virtual plane creation for warped surfaces

- Automatic tool path morphing

RTCP systems handle warped castings by creating virtual reference planes based on probe data from multiple measurement points. Furthermore, advanced algorithms calculate the optimal tool path modifications needed to maintain dimensional accuracy. Meanwhile, the system recognizes when distortion exceeds compensation limits and alerts operators accordingly. Additionally, some RTCP implementations can handle complex three-dimensional warping through advanced mathematical modeling.

The TCPC function for fixtures works in conjunction with industrial machinery to provide unprecedented flexibility. Therefore, manufacturers can process castings with moderate distortion while maintaining tight tolerances. Moreover, automotive casting machining benefits greatly from this capability since vehicle components often exhibit slight warping from the casting process. Consequently, rejection rates drop significantly when RTCP compensation is properly implemented.

What Accuracy Can You Expect After RTCP Compensation?

RTCP compensation delivers remarkable accuracy improvements compared to traditional fixturing methods. Moreover, real-world testing demonstrates consistent results across various casting materials and geometries. Consequently, manufacturers can achieve precision machining even with significant casting variations.

RTCP Accuracy Performance:

- Positional tolerance: ±0.05mm consistently achieved

- Surface finish: Ra 1.6μm on AZ91D magnesium

- Thermal drift compensation: 0.01mm accuracy at 40°C

- Bore diameter tolerance: ±0.03mm on 50-part test

- Repeatability: ±0.02mm across production runs

RTCP compensation achieves exceptional accuracy through continuous monitoring and adjustment of tool positions during machining operations. Furthermore, thermal compensation algorithms account for temperature-induced dimensional changes in both the workpiece and machine structure. Meanwhile, advanced filtering techniques eliminate vibration and dynamic errors that could affect surface finish quality. Additionally, statistical process control data from multiple production runs demonstrates the consistency and reliability of RTCP compensation.

The adaptive fixturing CNC technology ensures that surface finish requirements are consistently met across production batches. Therefore, manufacturers can confidently specify tight tolerances knowing that RTCP systems will deliver repeatable results. Moreover, the combination of accuracy and speed makes this technology particularly valuable for high-volume production environments. Consequently, return on investment often occurs within the first year of implementation.

Conclusion

RTCP die casting fixture technology represents a significant advancement in manufacturing capabilities. Furthermore, the 70% reduction in setup time delivers immediate productivity benefits while maintaining superior accuracy. Moreover, the ability to handle casting variations automatically eliminates many quality control issues. Additionally, the cost savings of $87.45 per setup cycle provide rapid return on investment.

Therefore, manufacturers should seriously consider RTCP implementation to stay competitive in today's demanding market. Finally, the combination of speed, accuracy, and reliability makes RTCP an invaluable tool for die casting operations. Consequently, companies that adopt this technology gain substantial advantages in both cost efficiency and product quality.

[External Links Recommendation]

[RTCP die casting fixture][^1]

[5-axis RTCP compensation][^2]

[die casting part localization][^3]

[automotive casting machining][^4]

[TCPC function for fixtures][^5]

[adaptive fixturing CNC][^6]

---

[^1]: Explore this link to understand the significance and applications of RTCP die casting fixtures in manufacturing processes.

[^2]: Learn about the benefits of 5-axis RTCP compensation in enhancing precision in machining operations.

[^3]: Discover various techniques for die casting part localization to optimize production efficiency and quality.

[^4]: Explore this link to understand the latest techniques and innovations in automotive casting machining, enhancing your knowledge and skills.

[^5]: Discover how TCPC functions can optimize your CNC machining processes, leading to improved accuracy and efficiency.

[^6]: Learn about adaptive fixturing to enhance your CNC machining capabilities, making your processes more flexible and efficient.