How Can SLA Bridge Tooling Cut Your Prototype-to-Production Time by 70%?

How Can SLA Bridge Tooling Cut Your Prototype-to-Production Time by 70%?

Product development teams face a costly dilemma when validating new designs. Traditional steel tooling requires $15,000-$25,000 upfront investment plus 8-12 weeks lead time before you can test even a single prototype part. However, what if there was a way to produce 200 functional validation parts in just 5 days for under $2,000? Therefore, SLA bridge tooling offers exactly this solution, allowing manufacturers to validate designs quickly before committing to expensive steel molds. Additionally, this approach has helped countless companies avoid costly design mistakes while accelerating their time-to-market significantly.

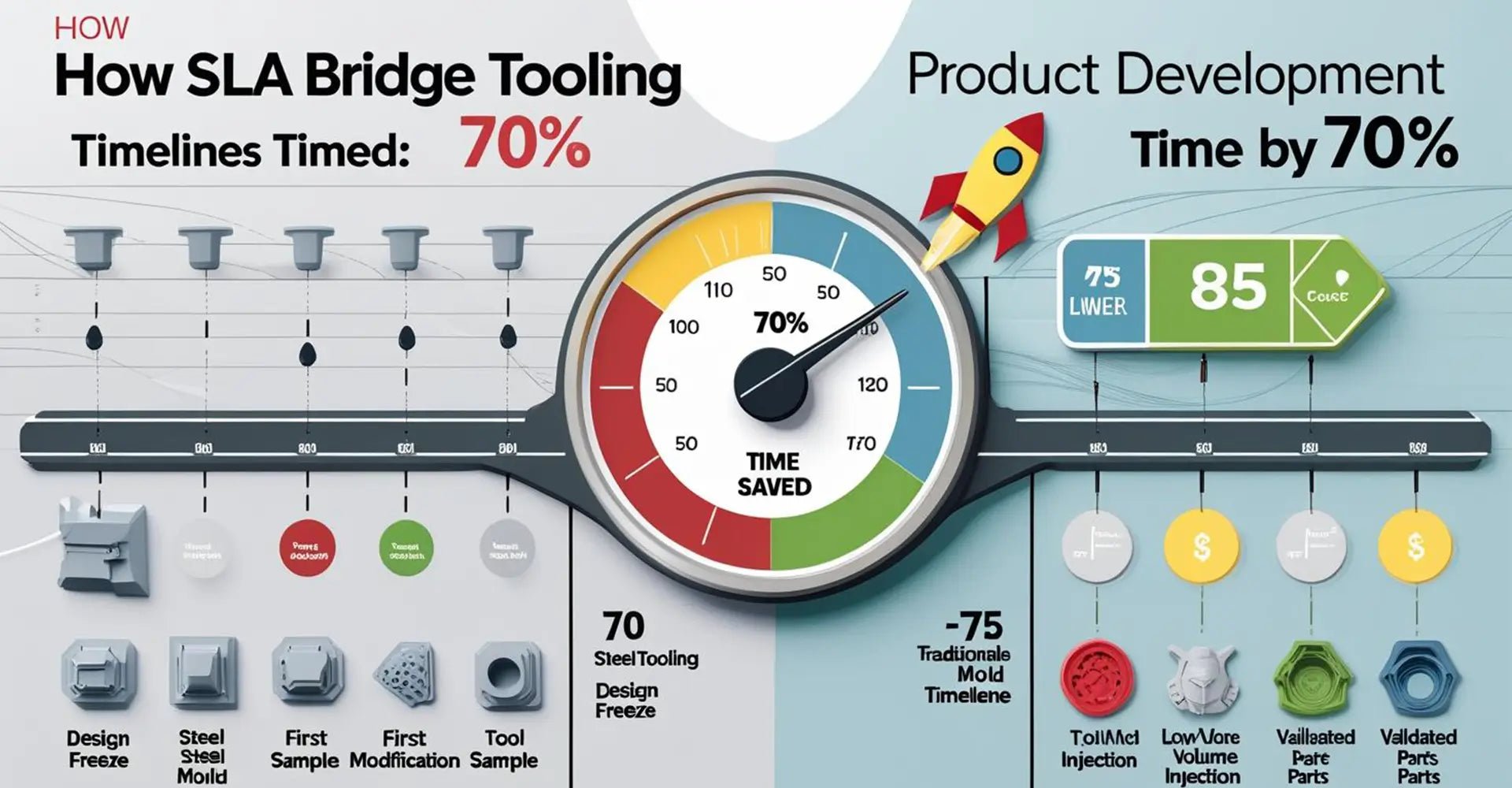

Quick Answer: SLA bridge tooling uses high-temperature stereolithography resins to create temporary injection molds that produce 200-300 functional parts for design validation. Consequently, this approach reduces initial tooling costs by 85% and accelerates the validation timeline from 8-12 weeks to 5-7 days. Furthermore, it enables rapid design iteration before steel mold investment, saving both time and money.

Understanding how SLA bridge tooling works and when to implement it can dramatically change your product development strategy. Moreover, this technology bridges the gap between single prototypes and full production runs. Let's explore the complete workflow from rapid prototyping through steel production.

[Table of Contents]

- Why Does Traditional Steel Tooling Create Validation Bottlenecks?

- What Makes SLA Bridge Tooling Ideal for 200-Unit Validation Batches?

- How Do You Transition from SLA Prototypes to Steel Production Molds?

- What Are the Real Cost Savings and Timeline Benefits?

Why Does Traditional Steel Tooling Create Validation Bottlenecks?

Manufacturing teams often get trapped in lengthy validation cycles when they jump straight to steel tooling for new product designs. Unfortunately, the traditional approach requires complete design freeze before mold fabrication begins. As a result, this leaves no room for iteration based on actual part testing.

The Problem: Steel molds cost $15,000-$25,000 and take 8-12 weeks to fabricate. Moreover, if design changes are needed after testing, you face additional $5,000-$8,000 modification costs plus 3-4 weeks delay. Consequently, this creates a 16-week average timeline from design to validated production samples. Additionally, many companies discover that their initial designs require significant modifications only after expensive tooling is already complete.

The root issue lies in the irreversible nature of steel tooling investment. Once machining begins, design modifications become extremely expensive through traditional CNC machining services. Additionally, steel molds require specialized cooling channel layouts and gate designs that may not work with your initial concept. Furthermore, many companies discover critical design flaws only after investing thousands in steel tooling, leading to costly redesign cycles.

Moreover, minimum order quantities from mold makers often force you to commit to final designs before adequate testing. This creates a chicken-and-egg problem that slows innovation significantly. In fact, industry studies show that 40% of new product launches require steel mold modifications, adding an average of $25,000 and 6 weeks to development timelines.

What Makes SLA Bridge Tooling Ideal for 200-Unit Validation Batches?

SLA bridge tooling bridges the gap between single prototype parts and full production by creating temporary injection molds from high-temperature resins. Specifically, these molds can produce functional parts using actual production materials for comprehensive validation testing. Therefore, bridge tooling for low-volume production has become increasingly popular among manufacturers seeking faster validation cycles.

The Solution: HiTemp SLA resins withstand injection molding temperatures up to 289°C (HDT) and produce molds with 0.1mm layer resolution. Furthermore, each SLA mold costs $800-$1,500 and produces 200-300 parts in ABS, PETG, or similar thermoplastics within 5-7 days total turnaround. Additionally, advanced 3D printing technology enables complex geometries that would be impossible with traditional machining methods.

The key advantage of SLA bridge tooling lies in its material flexibility and rapid turnaround. Unlike machined aluminum or steel, prototype molds with SLA resin can incorporate complex cooling channel geometries that would be impossible or extremely expensive to machine. Moreover, the resin material allows for intricate undercuts and detailed surface textures that perfectly replicate your intended design.

Furthermore, the 3D printing process enables you to test multiple gate locations and cooling strategies simultaneously by printing several mold variations. This parallel testing approach identifies the optimal mold design before committing to steel, significantly reducing the risk of production issues. Additionally, the validation parts produced are functionally identical to steel-molded parts, providing reliable data for stress testing, fit analysis, and market validation.

Importantly, rapid mold iteration with SLA 3D printing allows engineers to test design variations quickly. For instance, you can produce three different cooling channel configurations in the same timeframe that traditional methods would require for a single mold. Consequently, this accelerates the entire validation process while maintaining part quality standards.

How Do You Transition from SLA Prototypes to Steel Production Molds?

The transition from validated SLA prototypes to steel production molds becomes seamless when you design both tooling approaches from the same CAD models. Specifically, this workflow maintains design continuity while leveraging the strengths of each manufacturing method. Therefore, the 3D printed molds to steel tooling transition requires careful planning from the initial design phase.

The Process: Use identical gate locations, cooling channel layouts, and parting line designs in both SLA and steel molds. Consequently, this approach allows 90% of CAD data reuse, reducing CNC programming time by 60% and eliminating geometry translation errors. Additionally, this hybrid additive-subtractive manufacturing workflow combines the speed of 3D printing with the durability of traditional machining methods.

Successful transition requires upfront planning during the SLA mold design phase. First, start by defining your steel mold constraints - standard cooling channel diameters, available gate sizes, and CNC machining limitations. Then, design your SLA prototype molds within these parameters, even though 3D printing could handle more complex geometries. Therefore, this disciplined approach ensures that your validated SLA design translates directly to steel without geometry modifications.

Additionally, maintain identical injection molding parameters between SLA and steel trials - same temperatures, pressures, and cycle times. This consistency ensures that part properties remain stable across the transition. Furthermore, document all successful molding parameters during SLA validation, as these become your steel mold process specifications.

Most importantly, work with suppliers who understand this workflow and can efficiently convert your validated designs to steel tooling. Many companies that offer rapid prototyping services now specialize in this hybrid approach, providing seamless transitions from validation to production.

What Are the Real Cost Savings and Timeline Benefits?

The financial and schedule advantages of SLA bridge tooling become clear when you calculate the total cost of validation cycles. Specifically, traditional approaches often require multiple steel mold modifications, while SLA enables iteration before steel commitment. Therefore, cost reduction in injection mold tooling becomes significant when using this approach strategically.

The Numbers: SLA bridge tooling saves 85% on initial validation costs ($1,200 vs $18,000) and reduces timeline by 10-12 weeks. Moreover, failed designs are caught early, avoiding $20,000+ steel mold modification costs that affect 40% of new product launches. Additionally, validation sampling before mass production helps identify potential issues before they become expensive problems.

Real-world case studies demonstrate consistent savings across industries. For example, a coffee grinder manufacturer saved $35,000 and 12 weeks by validating their housing design through SLA bridge tooling before steel mold fabrication. Specifically, they discovered critical assembly issues during the 200-part validation run that would have required complete steel mold redesign. Furthermore, this early detection prevented costly production delays and customer dissatisfaction.

Similarly, an automotive supplier used SLA bridge tooling to test three different gate locations for a dashboard component. Consequently, they identified the optimal design that reduced cycle time by 15% in steel production. The total investment of $4,500 in SLA validation prevented $45,000 in steel mold modifications and associated production delays. Additionally, the supplier was able to deliver samples to their customer 8 weeks earlier than originally scheduled.

Moreover, the ability to provide actual molded parts to customers for approval accelerates sales cycles significantly. Often, this generates revenue during the validation phase that offsets SLA tooling costs entirely. Companies utilizing industrial machinery for high-volume production particularly benefit from this approach, as it ensures their final tooling investment produces parts that meet all specifications from day one.

Furthermore, SLA bridge tooling enables companies to test market acceptance with functional prototypes before committing to full production. This reduces the risk of product failures and helps validate demand before significant investment in production tooling.

Conclusion

SLA bridge tooling represents a strategic approach to product development that eliminates the costly risks of traditional steel-first workflows.

By implementing SLA bridge tooling for 200-unit validation batches, manufacturers can reduce prototype-to-production timelines by 70% while cutting initial tooling costs by 85%. Furthermore, this approach enables rapid design iteration, reduces steel mold modification risks, and provides functional parts for comprehensive validation testing.

Additionally, the seamless transition from validated SLA designs to steel production molds ensures design continuity while leveraging the speed advantages of additive manufacturing. Therefore, for product development teams facing tight launch schedules and budget constraints, SLA bridge tooling offers a proven path to faster, more cost-effective validation.

Most importantly, this methodology has been proven across multiple industries, from consumer products to automotive components. Companies that adopt this approach consistently report faster time-to-market, reduced development costs, and higher first-time success rates with their production tooling investments.

[External Links Recommendation]

[Rapid mold iteration with SLA 3D printing][^1]

[Bridge tooling for low-volume production][^2]

[3D printed molds to steel tooling transition][^3]

[Cost reduction in injection mold tooling][^4]

[Hybrid additive-subtractive manufacturing workflow][^5]

[ISO 9001-certified rapid tooling solutions][^6]

---

[^1]: Explore this link to understand how SLA 3D printing enhances mold iteration speed and efficiency, crucial for modern manufacturing.

[^2]: Discover the advantages of bridge tooling in low-volume production, which can save costs and time in manufacturing processes.

[^3]: Learn about the transition process from 3D printed molds to steel tooling, essential for scaling production and improving durability.

[^4]: Explore this resource to discover innovative strategies that can significantly lower your injection mold tooling costs, enhancing your production efficiency.

[^5]: Learn about the hybrid manufacturing workflow to understand how it combines additive and subtractive methods for improved efficiency and flexibility in production.

[^6]: Discover the advantages of ISO 9001 certification in rapid tooling, ensuring quality and reliability in your manufacturing processes.