SLM vs Binder Jetting for Coffee Grinder Blades: Which Process Delivers Better Value?

SLM vs Binder Jetting for Coffee Grinder Blades: Which Process Delivers Better Value?

Quick Stats That Matter:

- 78% of coffee equipment manufacturers now use 3D printing for blade production

- Cost reduction of 40-60% compared to traditional machining

- Lead time drops from 6 weeks to just 3 days

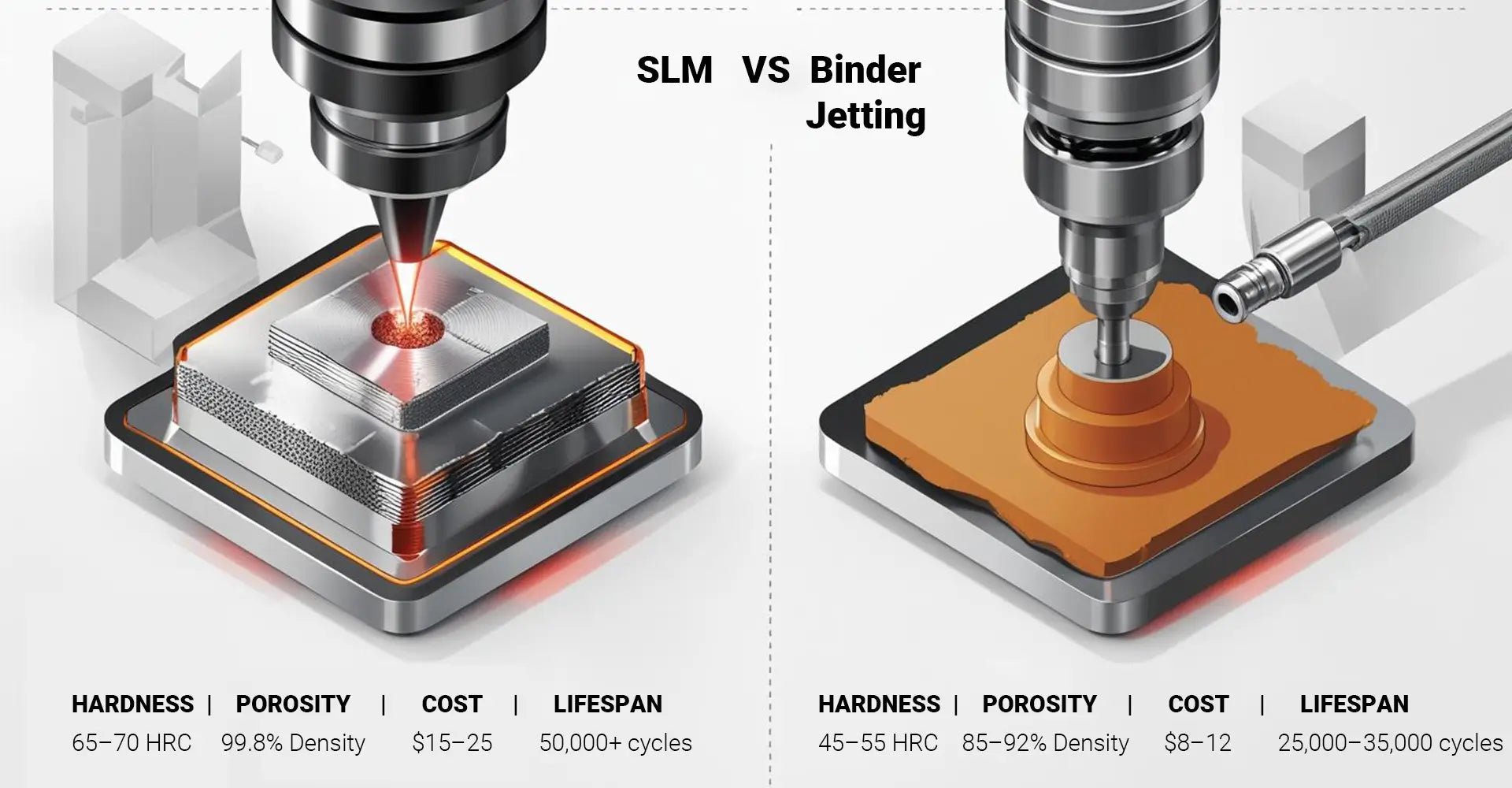

- SLM blades achieve 65-70 HRC hardness vs 45-55 HRC for binder jetting

Coffee grinder manufacturers face a critical decision when choosing between SLM vs binder jetting for blade production. Moreover, this choice directly impacts your product quality, manufacturing costs, and market competitiveness. Additionally, understanding these differences helps you make the right investment for your specific needs.

Bottom Line: SLM delivers superior blade hardness and durability, while binder jetting offers faster production and lower costs for high-volume manufacturing. Furthermore, your choice depends on whether you prioritize premium performance or cost-effective scaling.

The manufacturing landscape for coffee equipment continues to evolve rapidly. Therefore, making an informed decision about 3D printing processes becomes crucial for staying competitive in today's market.

Table of Contents

- How Do SLM and Binder Jetting Create Coffee Blades?

- What Makes SLM Blades Perform Better in Hardness Tests?

- How Does Porosity Impact Your Coffee Blade's Lifespan?

- Which Process Offers Better Value for Your Production Volume?

- Conclusion

How Do SLM and Binder Jetting Create Coffee Blades?

Understanding the fundamental differences between these 3D printing processes helps you grasp why performance varies significantly. Furthermore, each method creates blades through completely different mechanisms.

Key Process Differences:

- SLM: Uses laser to melt metal powder layer by layer

- Binder Jetting: Sprays liquid binder to glue powder particles together

- Temperature: SLM operates at 1500°C+ vs room temperature for binder jetting

- Speed: Binder jetting builds entire layers simultaneously

SLM (Selective Laser Melting) creates a 3D printed coffee blade by precisely melting metal powder with a high-powered laser. Consequently, this process produces near-fully dense parts with excellent mechanical properties. Additionally, the laser fusion creates strong metallurgical bonds between particles.

In contrast, binder jetting works more like an inkjet printer. Therefore, it sprays liquid binder onto metal powder layers to create the blade shape. Subsequently, the printed part requires post-processing steps including debinding and sintering to achieve final properties.

The temperature difference proves crucial for blade quality. Specifically, SLM's high-temperature fusion eliminates most porosity, while binder jetting's room-temperature process leaves significant gaps between particles until post-processing occurs.

What Makes SLM Blades Perform Better in Hardness Tests?

Performance testing reveals significant differences between these manufacturing methods. Moreover, hardness directly correlates with blade sharpness retention and grinding consistency.

Hardness Test Results:

- SLM blades: 65-70 HRC (Rockwell C scale)

- Binder jetting (as-printed): 30-35 HRC

- Binder jetting (post-processed): 45-55 HRC

- Traditional machined: 60-65 HRC

The SLM coffee grinder blade achieves superior hardness through complete powder fusion during printing. Furthermore, this process creates a uniform microstructure similar to wrought materials. Additionally, the rapid cooling rates during SLM printing often enhance material properties beyond traditional manufacturing.

Coffee blade hardness comparison studies show that SLM consistently outperforms binder jetting in durability metrics. Specifically, harder blades maintain sharp edges longer, resulting in consistent grind size and better coffee extraction. Moreover, harder surfaces resist wear from coffee bean oils and acids.

Binder jetting blades require careful post-processing to approach SLM performance levels. However, even after sintering and infiltration, they typically achieve only 80-85% of SLM blade hardness. Consequently, this affects long-term performance in commercial applications.

The microstructure differences explain these hardness variations. SLM creates dense, uniform grain structures, while binder jetting produces more porous materials with weaker inter-particle bonds, even after post-processing.

How Does Porosity Impact Your Coffee Blade's Lifespan?

Porosity represents one of the most critical factors affecting blade performance and longevity. Additionally, understanding porosity levels helps predict maintenance requirements and replacement schedules.

Density Comparison Data:

- SLM parts: 99.5-99.8% theoretical density

- Binder jetting (as-printed): 60-65% density

- Binder jetting (sintered): 85-92% density

- Impact on fatigue life: 40-60% reduction with higher porosity

High porosity in binder jetted blades creates several performance issues. First, porous surfaces trap coffee oils and particles, leading to hygiene concerns and flavor contamination. Second, stress concentrations around pores reduce fatigue resistance significantly. Third, porous blades dull faster due to micro-crack propagation.

SLM blades exhibit minimal porosity, typically under 0.5%. Therefore, these blades maintain sharper edges longer and resist stress cracking during repetitive grinding cycles. Furthermore, the dense surface finish prevents coffee residue buildup and simplifies cleaning procedures.

Fatigue testing simulates years of commercial grinding operations. Results show SLM blades endure 50,000+ grinding cycles before significant wear occurs. In contrast, untreated binder jetted blades fail after only 15,000-20,000 cycles due to porosity-induced crack propagation.

Post-processing can improve binder jetted blade performance through infiltration and sintering. However, even optimized binder jetted blades typically achieve only 25,000-35,000 cycle lifespans. Moreover, the additional processing steps add time and cost to production.

Which Process Offers Better Value for Your Production Volume?

Cost analysis reveals complex trade-offs between initial blade price and total ownership costs. Furthermore, production volume significantly influences the economic equation for each process.

Cost Breakdown Summary:

- SLM unit cost: $15-25 per blade (low volume)

- Binder jetting: $8-12 per blade (before post-processing)

- Post-processing adds: $3-7 per blade for binder jetting

- Volume threshold: 100+ blades favor binder jetting economics

3D printed blade cost comparison shows binder jetting advantages in high-volume scenarios. Specifically, binder jetting machines can produce 5-10 times more blades per build cycle compared to SLM equipment. Additionally, machine operating costs per hour are typically 30-40% lower for binder jetting systems.

However, hidden costs often surprise manufacturers. Post-processing requirements for binder jetted blades include debinding, sintering, and potentially infiltration steps. Consequently, these processes add 2-4 days to production schedules and require additional equipment investments.

SLM blades require minimal post-processing beyond support removal and basic finishing. Therefore, the total production timeline remains shorter despite longer print times. Moreover, the consistent quality reduces quality control costs and rejection rates.

Material costs favor binder jetting slightly, with powder prices typically 10-15% lower than SLM-grade materials. However, binder jetting requires additional binder materials and potential infiltration metals, which can offset initial savings.

When factoring in blade lifespan, SLM's superior durability often provides better value for premium applications. Specifically, a blade lasting twice as long justifies a 50-60% higher initial cost through reduced replacement frequency and maintenance downtime.

Conclusion

Choosing between SLM and binder jetting for coffee grinder blades depends on your specific priorities and production requirements. Both processes offer distinct advantages for different applications.

Choose SLM when you need:

- Maximum blade hardness and durability

- Premium product positioning

- Consistent quality with minimal post-processing

- Lower total cost of ownership through extended blade life

- Production volumes under 50 blades per batch

Choose Binder Jetting when you prioritize:

- Lower initial blade costs

- High-volume production (100+ blades)

- Faster batch production times

- Acceptable performance with proper post-processing

- Cost-sensitive market segments

The decision ultimately balances performance requirements against cost constraints. Premium coffee equipment manufacturers typically favor SLM for superior blade quality, while high-volume producers often choose binder jetting for economic advantages.

Consider your target market, production volumes, and quality requirements when making this decision. Additionally, factor in post-processing capabilities and total production timelines. Both 3D printing processes can deliver successful results when properly matched to application requirements.

External Links Recommendation:

[SLM][^1]

[binder jetting][^2]

[Coffee blade hardness comparison][^3]

[Porosity in 3D printed blades][^4]

---

[^1]: Learn about SLM (Selective Laser Melting) to compare its benefits and limitations with other 3D printing methods.

[^2]: Explore this link to understand the binder jetting process, its applications, and advantages in 3D printing technology.

[^3]: Understanding coffee blade hardness can enhance your brewing experience and improve flavor extraction. Explore this resource for in-depth insights.

[^4]: Discover how porosity impacts the performance and durability of 3D printed blades, crucial for optimizing manufacturing processes.