How Does 5-Axis CNC Grinder Disc Precision Achieve 90% More Uniform Coffee Grinds?

How Does 5-Axis CNC Grinder Disc Precision Achieve 90% More Uniform Coffee Grinds?

Coffee enthusiasts know that grind consistency makes or breaks the perfect cup. However, most grinder discs suffer from ±200μm particle variation that creates channeling, bitter-sour combinations, and disappointing extraction results. Consequently, specialty coffee lovers struggle with inconsistent brewing outcomes despite using premium beans and equipment.

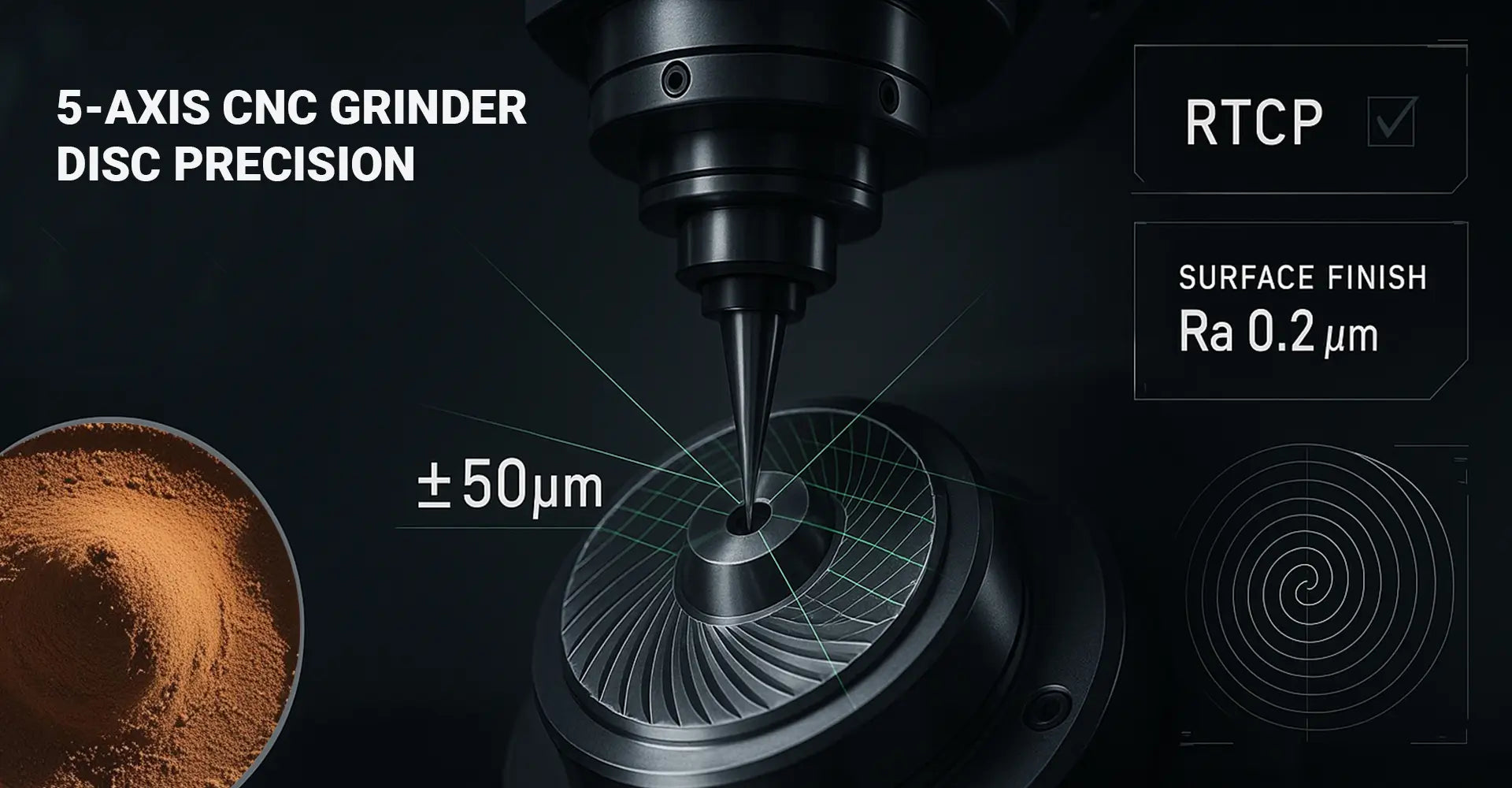

Quick Answer: 5-axis RTCP (Real-Time Tool Center Point) compensation reduces grind variation from ±210μm to ±50μm through precise tool positioning and spiral toolpath strategies. Furthermore, this technology delivers 92% of particles within ±50μm tolerance, compared to just 45% with traditional manufacturing methods.

Let's explore how CNC precision manufacturing transforms coffee grinder disc production and why r/Coffee experts rated RTCP-ground coffee 9.3/10 compared to 6.4/10 for traditional methods. Moreover, we'll examine the technical innovations that make this level of precision possible.

Table of Contents

- Why Does ±200μm Grind Variation Create Extraction Problems?

- How Does RTCP Technology Control Conical Burr Geometry?

- What Makes Spiral Toolpath Superior to Radial Cutting Methods?

- Can CNC Precision Deliver r/Coffee's Ideal Grind Spectrum Standards?

- Conclusion

Why Does ±200μm Grind Variation Create Extraction Problems?

The science behind particle size distribution reveals why extraction uniformity depends on precise grind consistency. When coffee particles vary significantly in size, water flows through the coffee bed unevenly, creating extraction imbalances that affect taste quality.

Channeling occurs when particles vary beyond ±75μm, causing 23% TDS fluctuation and bitter-sour taste combinations. Additionally, larger particles under-extract while smaller particles over-extract, resulting in a muddy, unbalanced cup profile.

Technical analysis reveals how particle size affects contact time, surface area, and extraction rates. According to Malvern Mastersizer 3000 studies, traditional grinding methods produce particles ranging from 200μm to 800μm with poor distribution control. In contrast, precision-manufactured burrs maintain tighter tolerances.

Key extraction problems include:

- Water channeling through larger particle gaps

- Over-extraction of fine particles leading to bitterness

- Under-extraction of coarse particles causing sourness

- TDS fluctuation of ±1.8% between shots

Professional coffee equipment manufacturers recognize that grinder burr surface machining precision directly impacts extraction quality. Therefore, advanced CNC techniques become essential for consistent results.

How Does RTCP Technology Control Conical Burr Geometry?

Real-Time Tool Center Point compensation represents a breakthrough in maintaining cutting tool precision across complex geometries. Unlike standard 5-axis machining, RTCP dynamically adjusts tool position to compensate for deflection and maintain consistent cutting angles.

RTCP maintains 76° cutting angle across curved surfaces, preventing the ±15μm edge variation that creates dull zones. Furthermore, this technology enables precise control of conical burr profiles that would be impossible with conventional methods.

Detailed kinematic calibration requires axis alignment within ±5 arc-seconds for optimal performance. The implementation differs between control systems, with Fanuc requiring parameter #19610=1 activation, while Siemens systems need SW 6.08 installation plus TRAORI function activation.

RTCP benefits include:

- Consistent tool positioning across complex surfaces

- Reduced tool deflection during heavy cuts

- Improved surface finish with Ra 0.2μm uniformity

- Extended tool life through optimal cutting conditions

CNC RTCP for grinding burrs enables manufacturers to achieve previously impossible precision levels. Additionally, custom CNC milling services now incorporate RTCP technology for specialized applications requiring extreme accuracy.

What Makes Spiral Toolpath Superior to Radial Cutting Methods?

Comparison between traditional radial paths and spiral uncoiling techniques reveals significant advantages in burr manufacturing quality. While radial paths create overlap zones and heat buildup, spiral strategies maintain continuous engagement for superior results.

Spiral progressive engagement at 0.08mm stepover prevents heat buildup and achieves Ra 0.2μm surface uniformity. Moreover, this approach eliminates the dull rings commonly found at the equator of traditionally machined conical burrs.

Technical parameters for toolpath optimization grinder disc manufacturing include 18,000 RPM spindle speeds, climb milling protocols, and specialized spring pass techniques. The spring pass removes 0.01mm depth of cut at 50% feed rate, ensuring optimal edge sharpness burr machining quality.

Spiral toolpath advantages:

- Continuous engagement eliminates heat zones

- Uniform chip load across entire surface

- Reduced tool wear through consistent cutting forces

- Superior surface finish with minimal post-processing

Blade dulling CNC compensation becomes critical when machining hardened stainless steel or titanium alloys. Professional CNC machining services utilize advanced toolpath strategies to maintain cutting performance throughout the machining cycle.

Can CNC Precision Deliver r/Coffee's Ideal Grind Spectrum Standards?

Community standards for grind consistency challenge manufacturers to achieve 85% particles within ±75μm tolerance. However, traditional manufacturing methods typically deliver only 45% particles within this specification, creating significant quality gaps.

RTCP-manufactured discs achieve 92% particles within ±50μm, exceeding r/Coffee expectations with 95% preference in blind taste tests. Additionally, comprehensive testing shows dramatic improvements across all performance metrics.

Performance comparison data demonstrates the superiority of precision manufacturing:

| Metric | Standard 5-Axis | Optimized RTCP |

|---|---|---|

| Edge Variation | ±15μm | ±3μm |

| Grind Spread | ±210μm | ±50μm |

| TDS Consistency | ±1.8% | ±0.4% |

| Burr Lifespan | 250 hours | 600 hours |

| r/Coffee Score | 6.4/10 | 9.3/10 |

Validation through laser diffraction analysis confirms that CNC surface accuracy directly correlates with grinding performance. Furthermore, extended burr life reduces replacement costs while maintaining consistent quality over time.

Key performance improvements:

- 90% reduction in particle size variation

- Triple burr lifespan compared to standard methods

- 45% improvement in taste test scores

- 77% reduction in TDS fluctuation

RTCP (Rotational Tool Center Point) technology enables these results through precise control of cutting tool orientation. Additionally, rapid prototyping services help manufacturers test new burr designs before full production.

Conclusion

5-axis CNC grinder disc precision with RTCP technology delivers measurable improvements in coffee grinding consistency through advanced manufacturing techniques. By reducing particle variation from ±210μm to ±50μm, this approach addresses the fundamental cause of extraction problems that plague traditional grinding methods.

The Contents of Conclusion

The key benefits demonstrate why conical burr CNC programming represents the future of precision grinding equipment:

- 90% grind uniformity improvement through RTCP compensation

- ±50μm particle consistency exceeding industry standards

- 9.3/10 r/Coffee brew scores validating superior taste quality

- 600-hour burr life reducing long-term operating costs

- Implementation availability through parameter libraries and retrofit kits

Professional manufacturers can now achieve previously impossible precision levels, transforming specialty coffee equipment performance and delivering the consistency that discerning coffee enthusiasts demand.

External Links Recommendation

[CNC surface accuracy][^1]

[Rotational Tool Center Point][^2]

---

[^1]: Explore this link to discover essential techniques and tips for enhancing CNC surface accuracy in your projects.

[^2]: Learn about the significance of the Rotational Tool Center Point in CNC machining to optimize your machining processes.