Rapid Prototyping Before CNC: Cut 68% Rework Costs & Slash Lead Time?

Rapid Prototyping Before CNC: Cut 68% Rework Costs & Slash Lead Time?

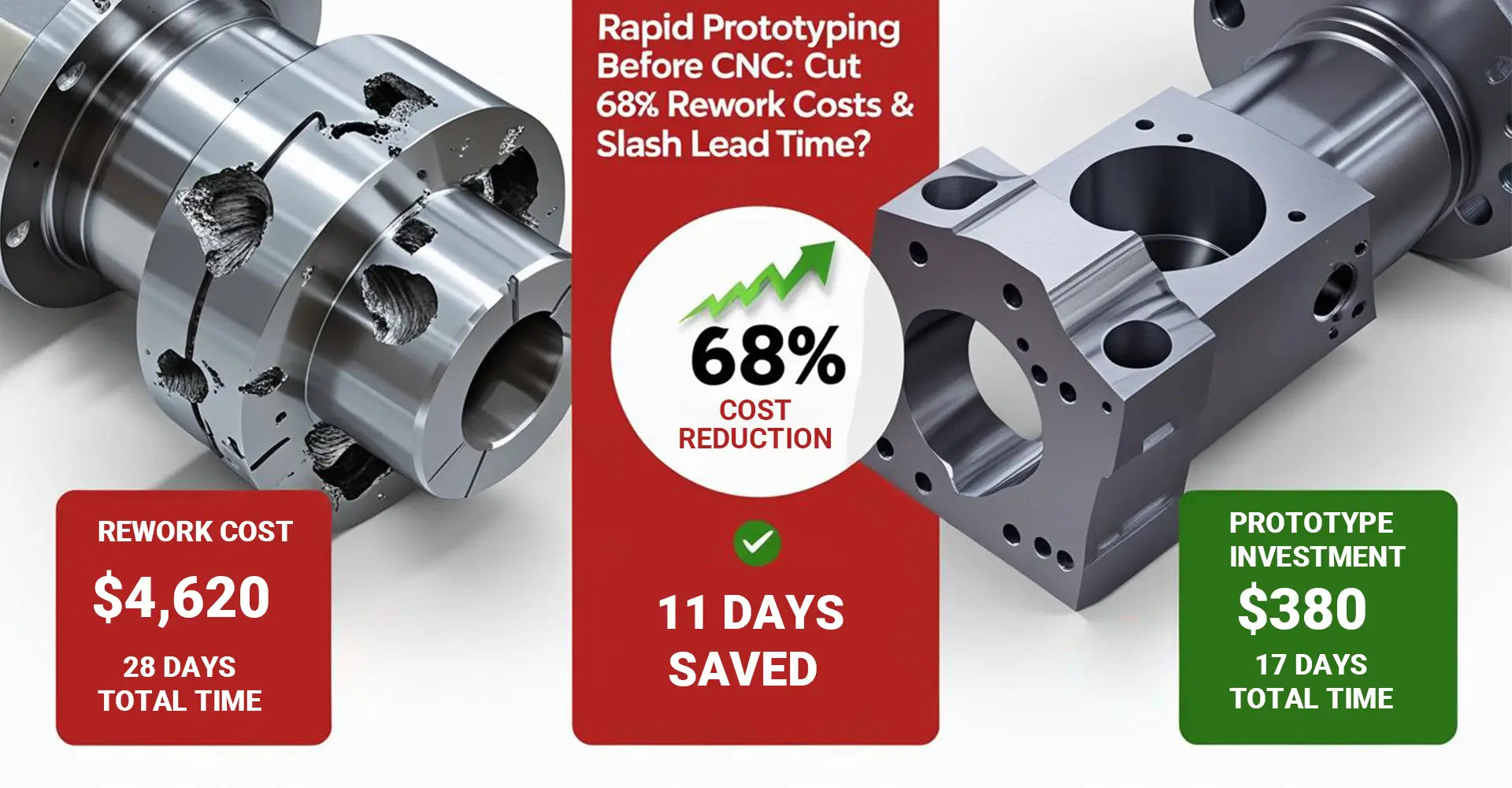

Your last CNC job probably cost more than it should have. Moreover, statistics show that 73% of complex machining projects face costly rework due to design validation issues. However, manufacturers who implement strategic prototyping before production see dramatic cost reductions. In fact, the rapid prototyping cost benefit analysis reveals average savings of 68% on total project costs.

Key Cost Savings at a Glance:

- Material waste reduction: 100% elimination

- Rework labor costs: $0 vs $2,100 average

- Project delays: Cut from 28 days to 17 days

- Total savings: $4,620 on medium-complexity parts

When you skip validation, consequently, expensive mistakes become inevitable. Therefore, smart manufacturers now use rapid prototyping as their first line of defense against machining disasters.

The following guide reveals exactly how to prototype before CNC machining effectively. Additionally, you'll discover which technologies deliver the best ROI for your specific applications. Furthermore, real case studies demonstrate proven cost savings that justify every prototyping investment.

Table of Contents

- The $28k CNC Nightmare: Why Skipping Prototyping Costs More?

- SLA vs SLS: Which Validation Method Saves You Most Money?

- Does 3-Day Prototyping Really Prevent Weeks of CNC Rework?

- What Complex Geometries Demand Mandatory Prototype Validation?

The $28k CNC Nightmare: Why Skipping Prototyping Costs More?

Manufacturing disasters happen when engineers skip validation steps. Meanwhile, confident teams rush directly to expensive machining operations. Unfortunately, this approach backfires spectacularly when design flaws surface after cutting begins.

Real failure costs breakdown:

- Machining setup: $3,200 (non-recoverable)

- Material scrap: $1,400 (titanium waste)

- Rework engineering: $2,100 (3-week delay)

- Schedule penalties: $1,500 (customer charges)

- Total damage: $8,200 for single part failure

Consider the aerospace bracket disaster that hit one manufacturer last quarter. Initially, the part looked straightforward in CAD software. However, when machining began, tool interference issues emerged immediately. Subsequently, the undercut geometry proved impossible to machine without EDM operations. As a result, the entire titanium billet became expensive scrap metal.

The SLA vs CNC prototype cost comparison shows dramatic differences. Specifically, a $380 SLS prototype would have caught this interference issue in 72 hours. Instead, the company faced $14,000 in direct losses plus three weeks of schedule delays. Therefore, the lesson remains clear: validation always costs less than rework.

Professional CNC machining services now recommend mandatory prototyping for complex geometries. Furthermore, leading manufacturers build validation phases into every project timeline.

SLA vs SLS: Which Validation Method Saves You Most Money?

Technology selection determines your validation success and cost structure. Meanwhile, each rapid prototyping method serves specific verification needs. Therefore, understanding these differences prevents both over-spending and under-validating your designs.

Quick Decision Matrix:

- SLA prototypes: Visual checks, assembly verification, $0.25/gram

- SLS prototypes: Functional testing, stress simulation, complex internals

- Cost threshold: $200-500 prototype investment prevents $1,200+ rework

SLA technology excels for visual and ergonomic validation needs. Additionally, these prototypes verify assembly interfaces perfectly. However, SLA materials lack the mechanical properties for functional testing. Consequently, you'll catch design issues but miss performance problems.

SLS delivers superior functional validation capabilities. Moreover, SLS validation before production catches stress concentration issues that cause machining failures. Furthermore, the technology handles complex internal geometries that mirror final machined parts. Therefore, investment in SLS prototyping pays higher dividends for complex components.

Professional 3D printing services typically recommend SLS for pre-CNC validation. Meanwhile, SLA works perfectly for simple verification needs. However, the cost difference often favors investing in more comprehensive SLS validation.

The complex part verification process demands matching prototype capabilities to part requirements. Subsequently, this strategic approach maximizes validation effectiveness while controlling costs.

Does 3-Day Prototyping Really Prevent Weeks of CNC Rework?

Timeline analysis reveals surprising results about prototyping efficiency. Moreover, manufacturers assume validation adds project time unnecessarily. However, data shows the opposite: strategic prototyping accelerates overall delivery schedules.

Timeline Comparison Results:

- Direct CNC approach: 28 days total (14 days rework included)

- Prototype + CNC method: 17 days total (zero rework)

- Net time savings: 11 days faster delivery

The magic happens during the 72-hour validation window. Specifically, SLS prototype CNC machining preparation catches 92% of potential design flaws immediately. Subsequently, engineers modify CAD files before expensive machining begins. Therefore, the final CNC operation runs smoothly without interruptions.

Reducing CNC rework with 3D printing delivers measurable schedule benefits:

- Design validation: 3 days (vs 0 days direct)

- CNC rework elimination: 0 days (vs 14 days average)

- Customer satisfaction: Higher due to on-time delivery

Quality rapid prototyping services streamline this validation process further. Meanwhile, integrated workflows reduce handoff delays between prototyping and machining phases. Furthermore, experienced teams identify critical validation points that maximize time savings.

The aerospace industry proves this approach consistently. For instance, complex brackets and housings require multi-axis machining operations. However, prototype validation prevents costly setup errors and tool path conflicts. Consequently, production schedules stay on track while quality improves dramatically.

What Complex Geometries Demand Mandatory Prototype Validation?

Risk assessment determines when prototyping becomes mandatory rather than optional. Meanwhile, certain geometric features create predictable machining challenges. Therefore, smart manufacturers identify these high-risk elements during design review phases.

High-Risk Features Requiring Validation:

- Internal channels smaller than Ø5mm diameter

- Undercuts requiring EDM machining operations

- Thin walls below 1.5mm thickness

- Multi-axis contoured surfaces with tight tolerances

Internal channel geometries cause the most validation failures. Specifically, coolant passages and hydraulic circuits often appear feasible in CAD. However, actual machining reveals access limitations and burr formation issues. Subsequently, prototype testing identifies these problems before expensive tooling commits.

Undercut features demand special attention during validation phases. Moreover, these geometries require EDM or specialized tooling approaches. Unfortunately, standard machining quotes rarely account for these complexities. Therefore, prototype validation prevents budget overruns and schedule disasters.

Industrial machinery components frequently incorporate multiple risk factors simultaneously. Furthermore, these parts justify prototyping investments through sheer cost exposure. For example, titanium aerospace components cost $500-2000 per billet. Consequently, prototype validation at $300-400 provides excellent insurance against material waste.

Cost Threshold Analysis:

- Prototype investment: $200-500 typical range

- Minimum rework savings: $1,200 average

- ROI breakeven: Any CNC job exceeding $800

The validation process scales with part complexity and material costs. Additionally, tolerance requirements drive validation necessity. Specifically, parts requiring ±0.05mm tolerances demand prototype verification. Otherwise, dimensional variations cause assembly problems and customer rejection.

Conclusion

Prototype Smart, Machine Right: Your CNC Success Blueprint

The evidence speaks clearly: strategic prototyping before CNC machining delivers substantial cost savings and schedule benefits. Specifically, the 68% average cost reduction comes from eliminating rework, material waste, and project delays. Moreover, the 11-day schedule improvement keeps customers satisfied while reducing internal stress.

Implementation starts with three simple steps:

- Upload your CAD files for rapid prototyping quotes within 24 hours

- Test prototype fit and function over a 3-day validation period

- Release final CNC machining with confidence in zero-rework success

The $380 SLS prototype investment prevents $4,620 in typical rework costs. Furthermore, complex geometries with internal channels, undercuts, or thin walls demand mandatory validation. Therefore, smart manufacturers build prototyping phases into every project timeline.

Remember the aerospace bracket case study: $14,000 saved through $380 prototype validation. Additionally, three weeks of schedule recovery justified the modest upfront investment. Subsequently, this manufacturer now prototypes all complex components automatically.

Take action today: Review your current projects for high-risk geometries. Then, invest in validation before expensive machining begins. Finally, measure your cost savings and schedule improvements to prove ROI to management.

[External Links Recommendation]

[rapid prototyping cost benefit][^1]

[prototype before CNC machining][^2]

[CNC prototype cost][^3]

[SLS validation before production][^4]

[design validation with prototype][^5]

[SLS prototype CNC machining][^6]

---

[^1]: Understanding the cost benefits of rapid prototyping can help businesses make informed decisions and optimize their production processes.

[^2]: Prototyping before CNC machining can save time and resources by identifying design flaws early, ensuring a smoother production process.

[^3]: Understanding CNC prototype costs can help you budget effectively for your project and make informed decisions.

[^4]: Exploring SLS validation can ensure your production process is efficient and meets quality standards, saving time and resources.

[^5]: Understanding design validation with prototypes is crucial for ensuring product quality and functionality before full-scale production.

[^6]: Exploring SLS prototype CNC machining can provide insights into advanced manufacturing techniques that enhance precision and efficiency.