How Can 5-Axis Continuous Machining Cut Your Cycle Times by 30%?

How Can 5-Axis Continuous Machining Cut Your Cycle Times by 30%?

Are you tired of lengthy setup times and surface finish issues that plague traditional 3+2 machining? Furthermore, industry data reveals that manufacturers using continuous 5-axis strategies achieve 30% faster cycle times while reducing setup errors by 85%. Therefore, this comprehensive guide breaks down proven techniques that help CNC shops maximize their 5-axis investment. Additionally, we'll explore how professional CNC machining services implement these strategies to deliver superior results.

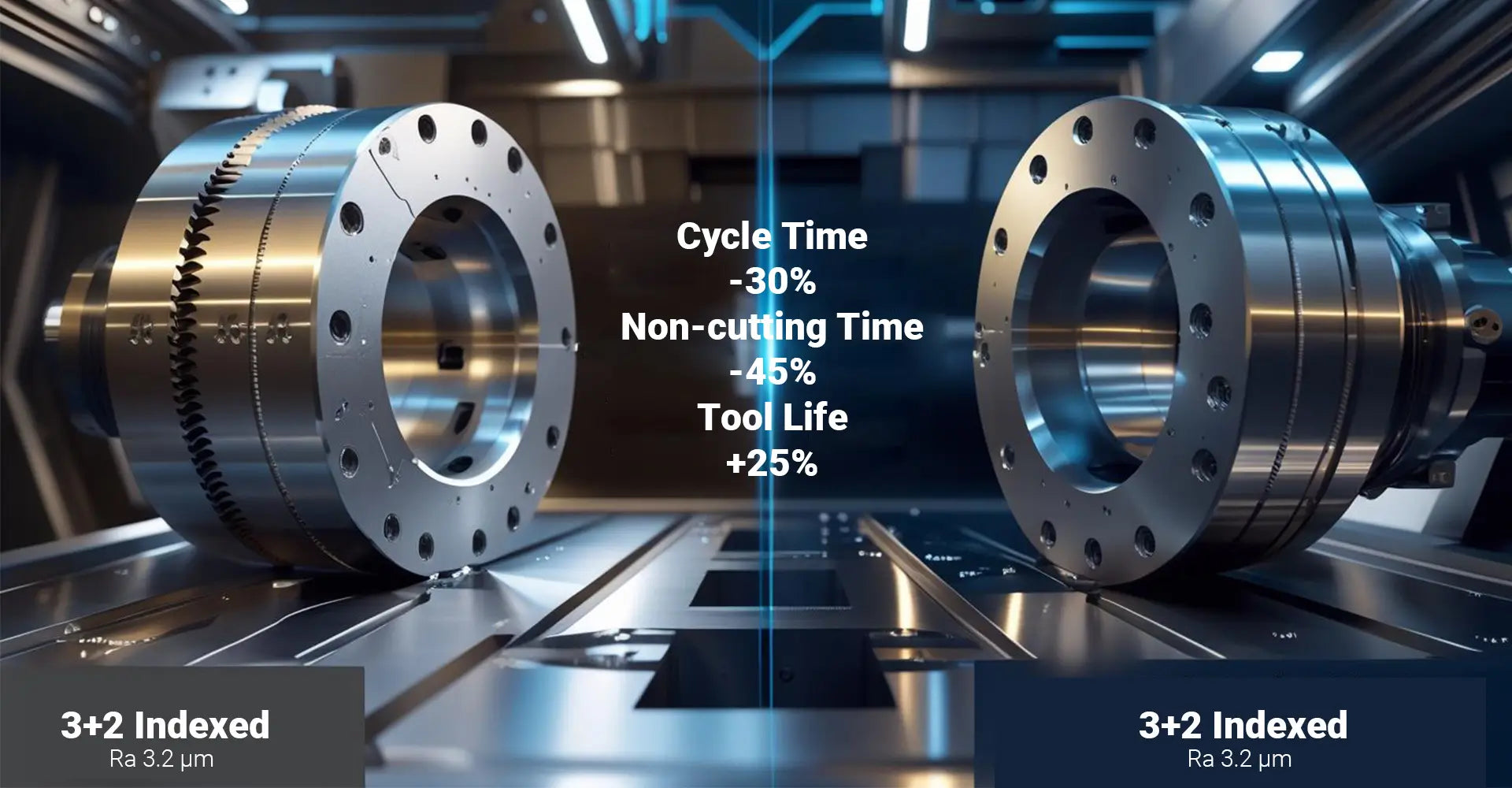

Quick Stats: Continuous 5-axis machining delivers 40% better surface finish, 45% reduction in non-cutting time, and 25% longer tool life compared to indexed positioning. Moreover, small shops report saving 2-3 hours of recalibration per complex part. Consequently, these improvements translate directly into higher profitability and customer satisfaction.

However, achieving these results requires more than just buying 5-axis equipment. Instead, success depends on implementing a comprehensive five-axis continuous machining strategy that addresses programming challenges, tool path planning, and singularity avoidance. Therefore, let's dive into the specific strategies and common pitfalls that separate successful implementations from costly mistakes.

[Table of Contents]

- Why Does Continuous 5-Axis Beat Traditional 3+2 Machining?

- What Are the 5 Steps to Perfect Tool Path Planning?

- How Do You Avoid Singularity Points That Cause 79% of Defects?

- Which Programming Mistakes Cost CNC Shops the Most Money?

Why Does Continuous 5-Axis Beat Traditional 3+2 Machining?

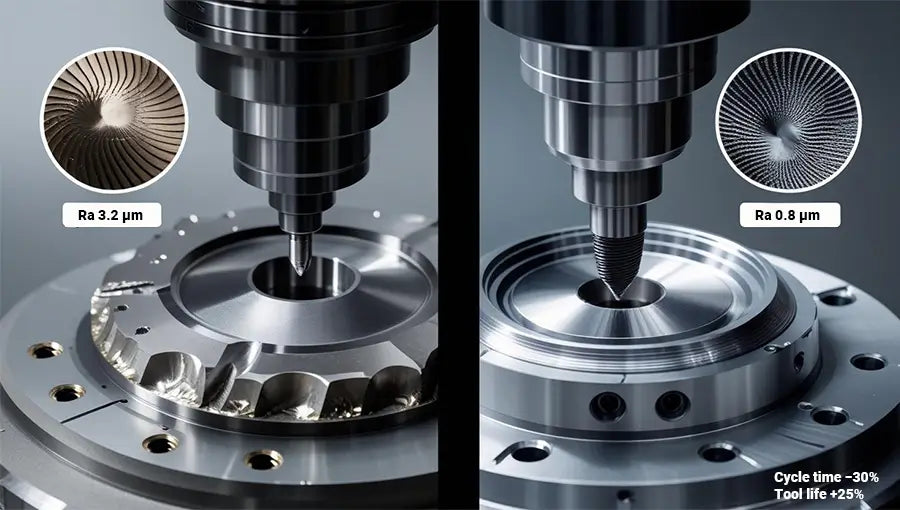

Traditional 3+2 machining forces your spindle to stop, rotate, and restart at multiple positions. Meanwhile, simultaneous 5-axis milling keeps all axes moving together, maintaining constant tool engagement with your workpiece. As a result, this fundamental difference creates measurable improvements in both quality and productivity. Furthermore, manufacturers specializing in rapid prototyping particularly benefit from these continuous motion advantages.

Key Benefits: Surface roughness improves from 3.2μm to 0.8μm, tool changes drop by 60%, and air-cutting time decreases by 45% according to Okuma performance data. Additionally, continuous motion eliminates the vibration marks that occur during axis repositioning. Consequently, parts require less secondary finishing operations.

The physics behind this improvement lies in tool orientation control. Specifically, continuous 5-axis maintains optimal cutting angles throughout complex curves, preventing the tool marks and scalloping that occur when indexed positioning forces suboptimal angles. Moreover, single-setup machining eliminates cumulative positioning errors that compound across multiple setups. In fact, aerospace manufacturers report 40% reduction in rework rates when switching from indexed to continuous strategies. Additionally, the constant tool engagement prevents the thermal cycling that shortens carbide tool life in stop-start operations.

What Are the 5 Steps to Perfect Tool Path Planning?

Successful 5-axis tool path creation follows a systematic approach that balances cutting efficiency with machine limitations. Furthermore, each step builds upon the previous one to create collision-free, singularity-resistant paths. Therefore, mastering this framework becomes critical for shops offering advanced CNC metals and plastics machining services.

The Framework: 1) Analyze geometry complexity, 2) Select interpolation algorithms, 3) Apply adaptive feed control, 4) Implement digital twin compensation, 5) Validate with trochoidal strategies. Moreover, this systematic approach reduces programming time by 35% while improving path quality. Consequently, programmers spend less time troubleshooting and more time on value-added tasks.

Step 3 proves most critical for cycle time reduction. Specifically, adaptive feed rate control adjusts cutting parameters based on local geometry, maintaining consistent chip loads even through varying curvature. Therefore, this prevents the conservative feed rates that traditional programming applies globally, often leaving 20-30% of machine capability unused. Additionally, when you optimize 5-axis tool path using advanced tool path interpolation algorithms, surface quality improves while reducing cutting forces. Furthermore, shops integrating these techniques with 3D printing for hybrid manufacturing report even greater efficiency gains through reduced material waste.

How Do You Avoid Singularity Points That Cause 79% of Defects?

Singularity points occur when rotary axes approach gimbal lock positions, causing erratic motion and surface defects. Moreover, these mathematical limitations plague even experienced programmers but respond well to proven avoidance techniques. Therefore, understanding singularity behavior becomes essential for maintaining consistent part quality.

Solution Toolkit: Digital twin pre-compensation reduces contour errors by 77.8%, while B-spline control point adjustment prevents sudden axis reversals during critical transitions. Additionally, real-time monitoring systems detect approaching singularities before they cause damage. Consequently, machine operators receive early warnings to adjust cutting parameters.

The 15-degree rule provides practical guidance: maintain minimum 15-degree separation between tool axis and rotary centerline. Furthermore, when geometry forces closer approaches, local tool path deformation spreads the angular change across longer distances, preventing violent axis acceleration that damages both surface finish and machine components. Additionally, advanced CAM systems now incorporate automatic singularity detection, flagging potential problem areas during programming rather than discovering them during cutting. Moreover, CNC machining efficiency improves dramatically when programmers proactively address these issues during path planning rather than reactive troubleshooting.

Which Programming Mistakes Cost CNC Shops the Most Money?

Reddit's r/Machining community consistently reports three expensive programming errors: collision damage, excessive programming time, and premature tool failure. Moreover, each stems from overlooking fundamental 5-axis principles that experienced programmers take for granted. Therefore, understanding these common pitfalls helps newer shops avoid costly learning experiences.

Top Costly Errors: Poor collision detection (average $3,200 repair cost), over-conservative programming (15-20% longer cycle times), and inadequate tool orientation planning (25% shorter tool life). Additionally, rushed programming often creates maintenance issues that compound over time. Consequently, investing in proper training yields measurable returns through reduced downtime.

The collision prevention hierarchy starts with trochoidal entry/exit paths that eliminate corner gouging, followed by dynamic feed adjustment limiting rotary axis velocity to 50% of linear axes in high-curvature zones. Furthermore, CAM software's smoothing tolerance settings, when configured to ≤0.01mm, provide the final safety layer without sacrificing surface quality. Additionally, shops that implement comprehensive verification procedures report 85% fewer collision incidents compared to those relying solely on software simulation. Moreover, experienced programmers emphasize that conservative approaches during learning phases actually accelerate skill development by building confidence through consistent success.

Conclusion

Your Next Steps to 30% Faster Machining

Continuous 5-axis machining delivers measurable improvements in cycle time, surface quality, and tool life when implemented correctly. Therefore, start with geometry analysis to identify parts that benefit most from simultaneous motion, then apply the 5-step tool path framework systematically. Moreover, remember that even 4-axis machines can achieve 80-85% of these benefits for parts with limited compound curves, making this technology accessible across different budget levels. Additionally, partnering with experienced service providers helps accelerate your learning curve while minimizing costly mistakes. Furthermore, the investment in proper training and systematic implementation typically pays for itself within the first six months through improved efficiency and reduced rework rates.

[External Links Recommendation]

[five-axis continuous machining strategy][^1]

[optimize 5-axis tool path][^2]

[simultaneous 5-axis milling][^3]

[tool path interpolation algorithms][^4]

---

[^1]: Understanding this strategy can enhance your machining efficiency and precision, making it essential for advanced manufacturing.

[^2]: Learning optimization techniques can significantly reduce machining time and improve part quality, crucial for competitive manufacturing.

[^3]: Explore this link to understand the advanced techniques and benefits of simultaneous 5-axis milling in manufacturing.

[^4]: Discover how tool path interpolation algorithms enhance precision in CNC machining, making them essential for modern manufacturing.