How Does Hybrid 3D Printing and CNC Turning Cut Shaft Production Costs by 35%?

How Does Hybrid 3D Printing and CNC Turning Cut Shaft Production Costs by 35%?

Manufacturing engineers face a persistent challenge when producing complex shafts with internal geometries. Traditional methods often fall short, leading to excessive costs and extended lead times. However, a groundbreaking approach is changing the game entirely.

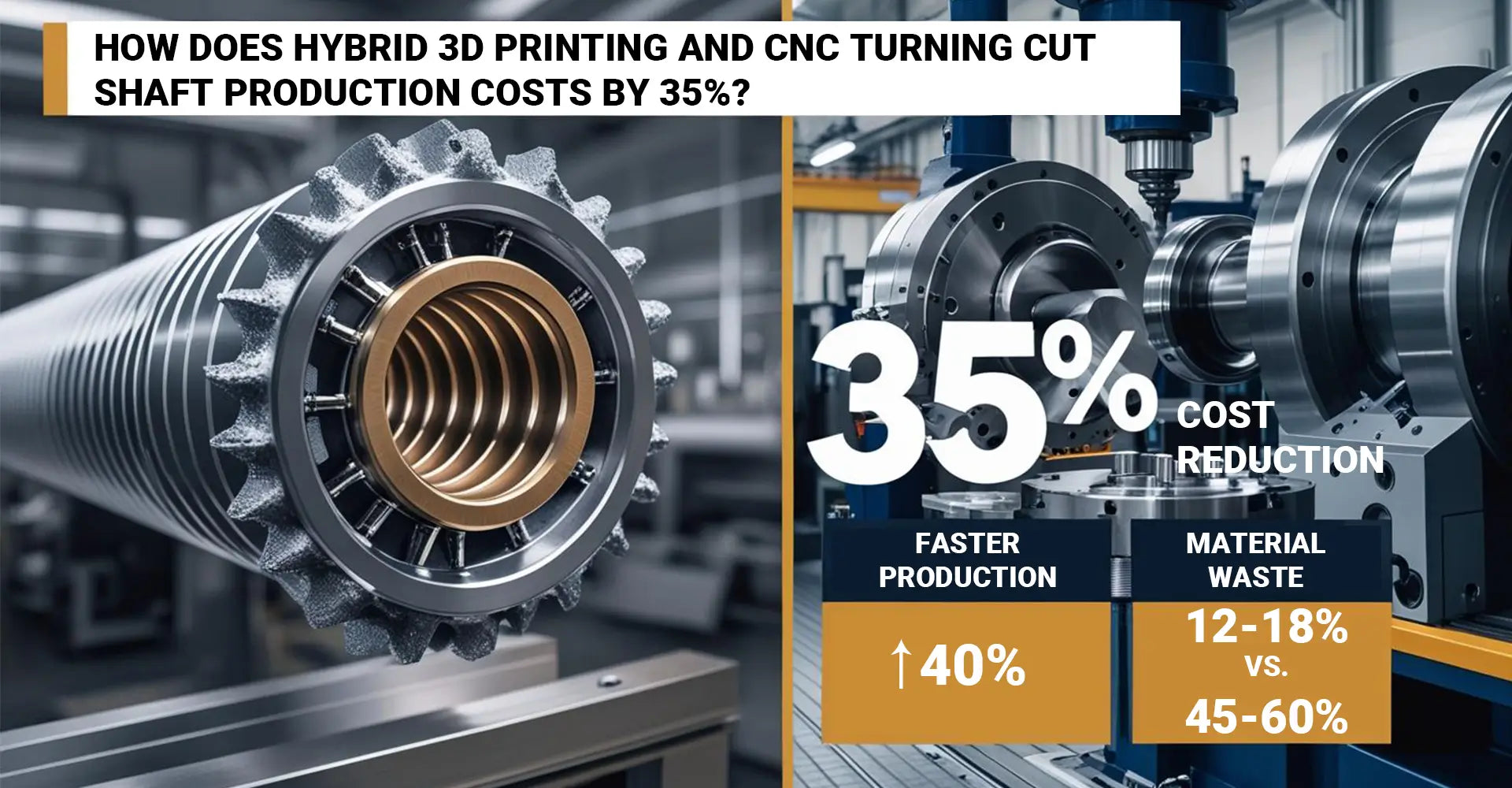

Key Benefits at a Glance:

- 35% cost reduction compared to pure CNC machining

- 40% faster production for complex geometries

- Single fixture setup eliminates multiple repositioning

- 12-18% material waste versus 45-60% in conventional methods

The hybrid 3D printing and CNC turning benefits are transforming how manufacturers approach complex shaft production. This integrated approach combines the geometric freedom of additive manufacturing with the precision of traditional machining.

Furthermore, this method addresses the growing demand for cost-effective, high-precision components across automotive, energy, and industrial applications. As production volumes increase and geometries become more complex, traditional methods simply cannot keep pace.

Table of Contents

- Why Do Traditional CNC Methods Struggle With Complex Internal Geometries?

- What Makes the Additive-Subtractive Workflow So Effective for Multi-Feature Shafts?

- How Do Hybrid Manufacturing Costs Compare Against Pure CNC and Pure 3D Printing?

- What Are the Most Common Hybrid Manufacturing Pitfalls and Prevention Strategies?

Why Do Traditional CNC Methods Struggle With Complex Internal Geometries?

Traditional machining faces fundamental limitations when dealing with complex shaft geometries. These constraints drive up costs and extend production timelines significantly.

The Core Problem: Conventional CNC machines cannot access enclosed internal features like helical channels, internal splines, or cooling passages. Consequently, manufacturers must resort to multiple setups, specialized tooling, and often assembly of separate components.

The mixed manufacturing CNC approach solves these accessibility issues by starting with a near-net shape 3D printed component. This eliminates the need for complex multi-axis machining operations that would otherwise be required for internal features.

Consider a turbine shaft with internal cooling channels. Traditional methods would require:

- Multiple setups: 4-6 different fixtures and orientations

- Specialized tooling: Custom long-reach tools costing $800-$1,500 each

- Assembly operations: Joining separate components with welding or brazing

- Quality challenges: Maintaining alignment across multiple operations

Additionally, material waste becomes excessive. A solid billet might lose 60% of its material when machining complex internal geometries. This waste translates directly to higher material costs and longer cycle times.

The accessibility problem extends beyond just internal features. External geometries with undercuts, reverse tapers, or complex surface transitions also present challenges for conventional CNC turning operations.

What Makes the Additive-Subtractive Workflow So Effective for Multi-Feature Shafts?

The additive-subtractive workflow combines the strengths of both manufacturing methods while minimizing their individual weaknesses. This approach delivers remarkable efficiency gains across the entire production process.

Step-by-Step Process Overview:

- Design for hybrid manufacturing - CAD models optimized for both processes

- 3D print near-net shape - 0.3mm machining allowance on critical surfaces

- Stress relief treatment - 650°C heat treatment to stabilize the part

- CNC finish operations - Precision turning of bearing surfaces and threads

The workflow begins with 3D printing the component to near-net shape. This creates all internal geometries, complex external features, and provides a stable foundation for subsequent machining operations.

Real-world data shows impressive time savings:

- Traditional CNC: 4.2 hours average per shaft

- Hybrid approach: 2.8 hours average per shaft

- Setup time: Reduced from 45 minutes to 12 minutes per batch

The complex shaft hybrid production process eliminates multiple fixture changes. Instead of repositioning parts 3-4 times, the printed base remains in a single fixture throughout CNC operations.

Material selection plays a crucial role in success. Maraging steel 1.2709 and Inconel 718 provide excellent machinability while maintaining structural integrity during turning operations.

Process parameters require careful control:

- Layer adhesion: Maintain 200°C build plate temperature

- Machining strategy: Climb milling with 0.1mm depth of cut for final passes

- Coolant application: Flood cooling during finish turning operations

How Do Hybrid Manufacturing Costs Compare Against Pure CNC and Pure 3D Printing?

Cost analysis reveals significant advantages for hybrid manufacturing across multiple production scenarios. The savings become more pronounced as part complexity increases.

Comprehensive Cost Breakdown (Per 100 Pieces):

| Cost Factor | Pure CNC | Pure 3D Printing | Hybrid Manufacturing |

|---|---|---|---|

| Material Waste | 45-60% | 5-8% | 12-18% |

| Labor Hours | 120 hrs | 85 hrs | 68 hrs |

| Tooling Costs | $2,800 | $350 | $900 |

| Total Cost | $24,600 | $18,300 | $16,100 |

The integrated 3D print and machining approach delivers the lowest total cost while maintaining high precision and surface quality. Material savings alone account for 20% of the cost reduction.

Labor efficiency improvements stem from several factors:

- Reduced setup time: Single fixture vs. multiple repositioning

- Faster material removal: Starting from near-net shape

- Eliminated secondary operations: No assembly or joining required

- Streamlined quality control: Fewer inspection points needed

Equipment investment varies significantly by production volume:

- Low volume (1-50 parts/month): Desktop hybrid systems under $50,000

- Medium volume (50-500 parts/month): Industrial platforms $200,000-$400,000

- High volume (500+ parts/month): Dedicated production lines $800,000+

ROI calculations show payback periods of 18-24 months for most applications. The break-even point occurs at approximately 200 parts for typical shaft geometries.

Cost variables to consider include:

- Material costs: Powder vs. solid stock pricing

- Energy consumption: Build time vs. machining time

- Post-processing requirements: Support removal and surface finish operations

- Quality costs: Reduced scrap rates offset higher material costs per pound

What Are the Most Common Hybrid Manufacturing Pitfalls and Prevention Strategies?

Despite its advantages, hybrid manufacturing presents unique challenges that can derail projects without proper preparation. Understanding these pitfalls enables successful implementation.

Top 3 Critical Pitfalls:

-

Layer Delamination During Machining

- Cause: Inadequate stress relief or excessive cutting forces

- Prevention: 650°C heat treatment and controlled cutting parameters

-

Tolerance Stack-up Issues

- Cause: Thermal expansion differences between processes

- Prevention: Compensation factors in CAD design and process planning

-

Surface Finish Inconsistencies

- Cause: Print layer visibility through thin machining allowances

- Prevention: Minimum 0.5mm allowance on cosmetic surfaces

Material selection mistakes account for 40% of hybrid manufacturing failures. Engineers must balance printability, machinability, and final part performance requirements.

Proven Prevention Strategies:

Material Guidelines:

- Avoid: Pure aluminum alloys (poor layer bonding)

- Prefer: Tool steels like H13 for structural integrity

- Consider: Maraging steels for aerospace applications

Process Control:

- Temperature monitoring: Maintain consistent build chamber conditions

- Tool selection: Use sharp, coated tools to minimize cutting forces

- Cutting fluid: Apply flood cooling to prevent thermal shock

Design Considerations:

- Draft angles: 3-5° minimum on all vertical surfaces

- Wall thickness: 0.8mm minimum to prevent vibration

- Support strategy: Minimize contact with finished surfaces

Quality control becomes more complex with hybrid processes. Traditional inspection methods may not capture process-specific issues like incomplete fusion or machining-induced stress concentrations.

Implementation success rates improve dramatically with proper training. Operators need skills in both additive and subtractive processes, along with understanding of their interactions.

Common workflow mistakes include:

- Insufficient stress relief time: Parts need 2-4 hours at temperature

- Improper fixture design: Must accommodate both printed and machined geometries

- Inadequate tool path planning: Requires specialized CAM software capabilities

Conclusion

Hybrid manufacturing represents a significant advancement in complex shaft production capabilities. The combination of additive and subtractive processes delivers substantial cost savings while maintaining high precision requirements.

The data clearly demonstrates the advantages: 35% cost reduction, 40% faster production, and dramatically reduced material waste. These benefits become even more pronounced as part complexity increases and production volumes scale.

Success requires careful attention to material selection, process parameters, and quality control methods. However, manufacturers who master these techniques gain significant competitive advantages in their markets.

The technology continues advancing rapidly. New materials, improved equipment, and better software integration promise even greater benefits in the coming years. Early adopters position themselves to capitalize on these developments.

For automotive applications, hybrid manufacturing enables previously impossible geometries while reducing costs. Energy and industrial sectors see similar advantages, particularly for low-to-medium volume production runs.

The investment in hybrid manufacturing capabilities pays dividends through reduced lead times, lower costs, and expanded design possibilities. Companies serious about competitive manufacturing should evaluate this technology for their complex shaft production needs.

External Links Recommendation

[hybrid 3D printing and CNC turning benefits][^1]

[mixed manufacturing CNC][^2]

[complex shaft hybrid production][^3]

[additive-subtractive workflow][^4]

[integrated 3D print and machining][^5]

[time savings hybrid manufacturing][^6]

---

[^1]: Discover how combining these technologies can enhance production efficiency and product quality.

[^2]: Learn about the innovative approaches in CNC that optimize manufacturing processes and reduce costs.

[^3]: Explore this link to understand the innovative techniques and benefits of complex shaft hybrid production in modern manufacturing.

[^4]: Discover how an additive-subtractive workflow can enhance efficiency and precision in manufacturing, making it a game-changer.

[^5]: Explore this link to understand how integrated 3D printing and machining can enhance efficiency and reduce production costs.

[^6]: Discover insights on how hybrid manufacturing techniques can significantly cut down production time and improve overall workflow.