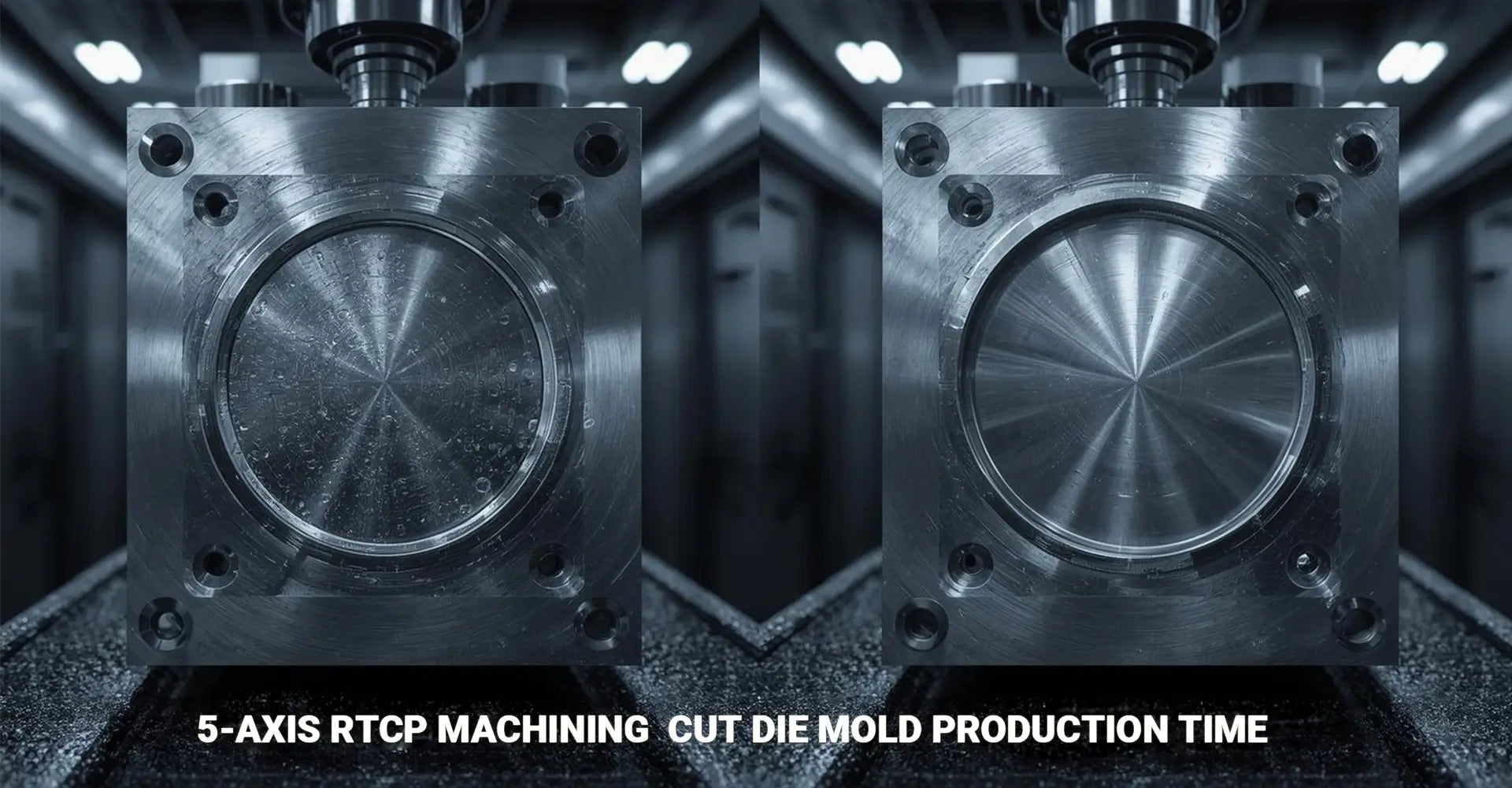

Can 5-Axis RTCP Machining Really Cut Your Die Mold Production Time in Half?

Can 5-Axis RTCP Machining Really Cut Your Die Mold Production Time in Half?

Mold makers across the industry are reporting dramatic time savings with 5-axis CNC technology. However, many shops remain skeptical about the actual benefits. This comprehensive guide examines real data from mold production facilities to answer whether 5-axis die mold machining with RTCP truly delivers on its promises. Moreover, we'll explore how this technology transforms complex mold manufacturing workflows.

Quick Answer: Yes, 5-axis CNC with RTCP can reduce mold machining time by 40-60% primarily through setup elimination. Traditional 3-axis requires multiple repositioning operations, while RTCP mold manufacturing completes complex cavities in one clamping. Additionally, better tool access enables higher cutting parameters and superior surface finishes that often eliminate secondary operations.

While the time savings are real, understanding exactly how this technology works requires examining specific applications and data. Therefore, let's break down the mechanics behind these impressive results and explore when 5-axis provides the greatest advantage for mold production.

Table of Contents

- What Makes RTCP Technology So Powerful for Complex Cavity Machining?

- How Does Single Setup Machining Actually Save 50% Production Time?

- Which Mold Features Benefit Most from 5-Axis CNC Capabilities?

- What Are the Real Costs and ROI of Upgrading to 5-Axis Die Mold Manufacturing?

- Conclusion

What Makes RTCP Technology So Powerful for Complex Cavity Machining?

RTCP (Rotational Tool Center Point) represents the breakthrough that makes 5-axis mold machining practical. Before RTCP, programming 5-axis operations required complex calculations for every tool movement. Now, machinists can focus on mold geometry rather than machine kinematics. Consequently, this technology has become the foundation for complex cavity machining in modern mold shops.

Key Benefit: RTCP automatically compensates for tool orientation changes, maintaining precise cutting point location regardless of how the head or table rotates. This enables smooth toolpaths on curved surfaces and eliminates the programming complexity that previously made 5-axis impractical for many shops. Furthermore, it allows machinists to program based on part geometry rather than machine movements.

The controller uses mathematical models to calculate exact axis movements during operation. When machining a curved mold surface, the tool can maintain constant contact angle while following the contour. This prevents gouging on deep cavities and ensures consistent chip load throughout the cut. Furthermore, RTCP enables the use of shorter, more rigid tools since better access angles are possible. The result is reduced vibration and improved surface quality that often eliminates secondary finishing operations. Advanced CNC machining services now leverage this technology to deliver superior mold components with dramatically reduced lead times.

How Does Single Setup Machining Actually Save 50% Production Time?

The most significant time savings come from eliminating multiple setups in reduced setup mold machining workflows. Traditional 3-axis mold machining requires repositioning the workpiece several times to access different surfaces. Each repositioning adds hours to the process and introduces potential accuracy issues. Therefore, understanding the time breakdown reveals why single setup provides such dramatic improvements.

Time Breakdown: A typical complex mold core that requires 8 hours with traditional methods breaks down as: 3 hours actual machining + 5 hours setup, inspection, and repositioning. With single setup machining, this becomes: 4 hours total (3.5 hours machining + 0.5 hours initial setup). The math clearly demonstrates where the savings originate.

Beyond time savings, single setup machining eliminates cumulative positioning errors that plague multi-setup operations. Each repositioning introduces small inaccuracies that compound throughout the process. Moreover, the reduced handling minimizes workpiece damage risk during transfers. Operators spend less time on fixturing and more time on productive machining activities. The workflow becomes more predictable, allowing better scheduling and resource allocation across the shop floor. This consistency particularly benefits die casting mold production where dimensional accuracy is critical for part quality.

Which Mold Features Benefit Most from 5-Axis CNC Capabilities?

Not all mold features require 5-axis CNC for die casting mold capabilities. Understanding which applications provide the greatest return helps shops prioritize their 5-axis usage and justify equipment investments. Certain geometries simply cannot be machined effectively with traditional methods. Therefore, identifying these high-impact features guides smart technology adoption decisions.

Highest Impact Features: Deep narrow cavities (aspect ratio >3:1), compound angle cooling channels, curved surface machining requiring superior finish, and undercuts accessible only with tilted tools. These features typically see 60-80% time reduction compared to alternative methods like EDM or extensive handwork. Additionally, deep hole drilling mold operations benefit significantly from improved access angles.

Deep hole drilling at compound angles becomes straightforward with 5-axis positioning capabilities. Previously, such holes required special fixtures or multiple operations with significant setup time. Curved surface machining benefits enormously from constant tool perpendicularity, reducing scallop marks and eliminating extensive polishing requirements. Additionally, undercut features that would require costly EDM electrodes can now be directly machined. The improved surface finishes often eliminate secondary operations entirely, providing additional time and cost savings beyond the primary machining reduction. Professional surface finish services recognize these advantages when specifying mold manufacturing requirements.

What Are the Real Costs and ROI of Upgrading to 5-Axis Die Mold Manufacturing?

Investment in 5-axis technology requires careful analysis of both direct and indirect benefits. While the equipment cost is substantial, the return comes from multiple sources beyond just cycle time reduction CNC capabilities. Smart shops calculate ROI based on comprehensive operational improvements including quality gains and expanded market opportunities.

ROI Factors: Equipment cost ranges $300K-$800K, but payback typically occurs within 2-3 years through: 50% cycle time reduction, 30% labor cost decrease, ability to quote previously impossible projects, and improved delivery times that command premium pricing. Additionally, mold finish improvement reduces downstream processing costs significantly.

The hidden benefits often exceed the obvious time savings in mold production operations. Shops report winning bids on complex projects previously declined due to technical limitations. Faster delivery times allow premium pricing and improved customer relationships throughout the supply chain. Reduced operator involvement frees skilled machinists for other value-added tasks and strategic activities. Quality improvements reduce warranty claims and rework costs significantly. Additionally, the capability to machine features previously requiring EDM or extensive handwork opens new revenue streams and market segments. Industrial machinery investments of this magnitude require comprehensive analysis, but the data supports strong returns for shops handling sophisticated mold work.

Conclusion

Conclusion Content

5-axis RTCP machining delivers measurable benefits for mold manufacturing, particularly for complex geometries requiring multiple setups with traditional methods. The technology provides genuine 40-60% time reductions through setup elimination, improved tool access, and enhanced surface quality. While the investment requires significant capital and training commitment, the combination of reduced cycle times, improved quality, and expanded capabilities provides compelling ROI for shops handling sophisticated mold work. Success depends on proper application selection and understanding where 5-axis provides the greatest advantage over conventional approaches. Smart implementation focuses on high-impact features while gradually expanding capabilities as experience grows.

[External Links Recommendation]

[5-axis die mold machining][^1]

[RTCP mold manufacturing][^2]

[5-axis CNC for die casting mold][^3]

[reduced setup mold machining][^4]

[complex cavity machining][^5]

[deep hole drilling mold][^6]

---

[^1]: Exploring this link will provide insights into the advantages and applications of 5-axis machining in mold manufacturing.

[^2]: This resource will help you understand how RTCP technology enhances mold manufacturing accuracy and efficiency.

[^3]: Explore this link to understand how 5-axis CNC technology enhances precision and efficiency in die casting mold production.

[^4]: Discover insights on how reduced setup times can significantly boost productivity and cost-effectiveness in mold machining.

[^5]: Explore this link to understand advanced techniques and technologies that enhance precision in complex cavity machining.

[^6]: Discover this resource to learn about the benefits and applications of deep hole drilling in mold making.