Which Aluminum Surface Finish Makes Your Coffee Machine Last 10+ Years?

Which Aluminum Surface Finish Makes Your Coffee Machine Last 10+ Years?

Coffee machine manufacturers spend countless hours perfecting brewing technology, yet many overlook one critical factor that determines long-term success: aluminum surface finish coffee machine selection. The wrong choice can lead to corrosion, scratches, and customer complaints within months. However, the right finish creates a protective barrier that withstands daily use, coffee spills, and cleaning chemicals for over a decade.

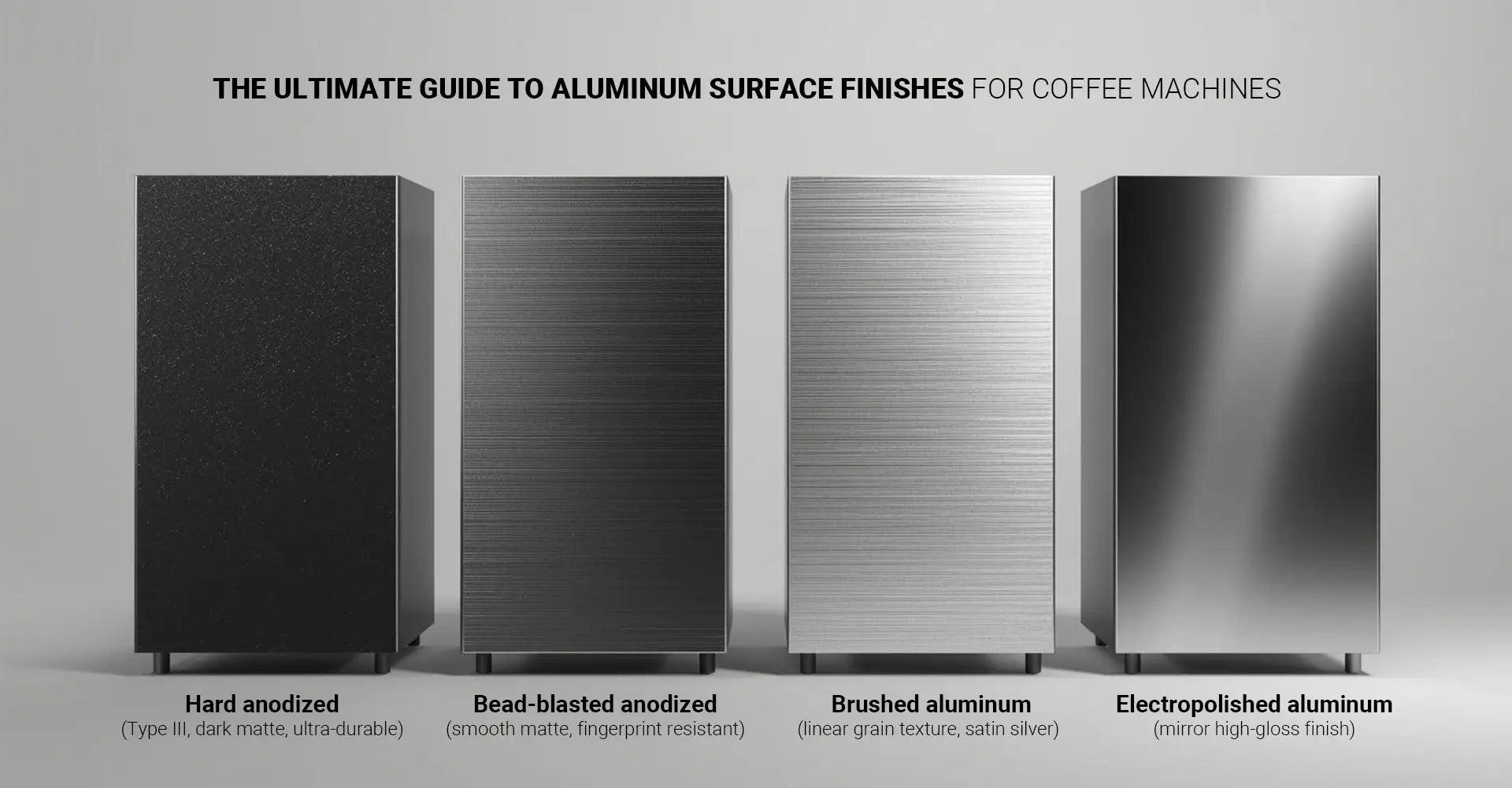

Quick Answer: Hard anodizing (Type III) provides the longest-lasting protection for coffee machine housings, creating surfaces 30% harder than tool steel. Meanwhile, bead-blasted anodized aluminum offers the best fingerprint resistance, and electropolishing delivers premium aesthetics. Cost ranges from $5-50 per housing depending on the finish type.

Understanding aluminum surface finishes isn't just about aesthetics—it's about creating products that maintain their appearance and performance throughout years of daily brewing cycles. Furthermore, proper surface finish selection can reduce warranty claims by up to 40% while enhancing brand reputation. Let's explore how each finish type performs in real-world coffee machine applications.

Table of Contents

- How Does Anodizing Protect Your Coffee Machine Housing?

- Why Do Manufacturers Choose Bead Blasting for Coffee Equipment?

- When Should You Select Brushed Aluminum for Your Coffee Grinder?

- Which Surface Treatment Offers the Best Value for Money?

How Does Anodizing Protect Your Coffee Machine Housing?

Anodizing creates an aluminum oxide layer that bonds permanently to the base material, unlike coatings that can chip or peel over time. This process literally grows the protective surface from the aluminum itself, making it impossible to separate under normal use conditions. Additionally, this technique provides superior coffee machine corrosion resistance compared to mechanical finishes alone.

Key Benefits: Type II anodizing provides excellent corrosion resistance at $15-30 per housing, while Type III hard anodizing creates surfaces harder than tool steel for $25-50 per housing. Both offer permanent color options that won't fade or chip.

The aluminum anodizing process uses controlled oxidation to build protective layers ranging from 5-25 microns thick. Type II anodizing suits most anodized aluminum coffee machine housing applications with its balance of protection and cost. However, high-volume commercial equipment benefits from Type III hard anodizing, which creates surfaces resistant to coffee acids, cleaning chemicals, and heavy daily use. Moreover, the electrolytic coloring process infuses permanent colors deep into the oxide structure, eliminating concerns about color fading or chipping that plague painted surfaces. This makes anodizing particularly valuable for premium coffee equipment where appearance and durability must coexist seamlessly.

Why Do Manufacturers Choose Bead Blasting for Coffee Equipment?

Bead blasting creates uniform matte textures that hide fingerprints and minor scratches—critical advantages for coffee equipment that faces constant handling. This mechanical finishing process uses glass beads to create consistent surface textures across complex geometries. Consequently, the bead blasting aluminum finish has become increasingly popular among manufacturers seeking both functionality and aesthetics.

Performance Data: Bead-blasted surfaces combined with anodizing show 75% better fingerprint resistance compared to brushed finishes. The process costs $5-15 per housing and creates surfaces that maintain their appearance despite daily cleaning routines.

The bead blasting process removes minor surface defects while creating micro-textures that diffuse light and hide imperfections. When combined with anodizing, these textured surfaces develop enhanced durability and stain resistance. Manufacturers particularly value bead blasting for visible surfaces like control panels and housing exteriors, where maintaining a clean appearance despite heavy use becomes crucial. Furthermore, the uniform matte finish also provides excellent adhesion for subsequent anodizing treatments, creating a synergistic effect that outperforms either process alone. This combination proves especially effective for commercial coffee equipments that endure intensive daily operations.

When Should You Select Brushed Aluminum for Your Coffee Grinder?

Brushed aluminum finishes create linear textures that complement contemporary kitchen aesthetics while providing practical benefits for coffee grinding equipment. The directional grain pattern helps mask scratches that occur naturally during operation and maintenance. This approach represents one side of the aluminum brushing vs anodizing debate, where each technique offers distinct advantages.

Application Benefits: Brushed finishes cost $5-15 per housing and work exceptionally well for coffee grinder surface finish applications where the linear texture aligns with the cylindrical form. Combined with clear anodizing, brushed surfaces maintain their appearance for 5-8 years under normal use.

Brushing creates controlled directional scratches that serve both aesthetic and functional purposes. The linear grain pattern naturally guides the eye along the product's form while helping conceal operational wear patterns. For coffee grinders, where vibration and movement are constant factors, brushed surfaces maintain their intended appearance longer than mirror finishes. The key lies in proper grain direction selection—vertical brushing suits tall housings, while horizontal grains complement wide bases and control areas. When followed by clear anodizing, brushed surfaces develop enhanced scratch resistance while preserving their distinctive texture. This aluminum housing surface treatment approach balances cost-effectiveness with visual appeal, making it ideal for mid-range product positioning.

Which Surface Treatment Offers the Best Value for Money?

Cost-effectiveness in aluminum finishing depends on balancing upfront investment against long-term performance requirements. Different applications demand different approaches to achieve optimal value propositions. Therefore, conducting an aluminum finish durability comparison becomes essential for making informed decisions.

Cost Analysis: Standard anodizing ($15-30) provides the best overall value for most coffee machine applications, offering excellent protection and aesthetics. Bead blasting + anodizing combinations ($20-45) suit premium products, while basic brushing ($5-15) works for budget-conscious designs.

Value assessment requires considering total lifecycle costs, including initial finishing expenses, maintenance requirements, and replacement frequency. Standard Type II anodizing typically provides the sweet spot for most manufacturers, delivering professional appearance and solid protection at reasonable cost. Premium products justify hard anodizing's higher initial investment through reduced warranty claims and enhanced brand perception. Budget-conscious manufacturers can achieve acceptable results with mechanical finishes like brushing, provided they apply appropriate protective clear coatings. Meanwhile, electropolishing aluminum offers premium aesthetics for luxury segments, while powder coating aluminum provides excellent color variety for brand customization. The key lies in matching finish selection to product positioning and target market expectations rather than simply choosing the lowest-cost option.

Conclusion

Selecting the right aluminum surface finish for coffee machines requires balancing durability, aesthetics, and cost considerations specific to your application. Hard anodizing delivers maximum longevity for premium products, while standard anodizing provides excellent value for most applications. Bead blasting excels at hiding fingerprints and wear, making it ideal for high-touch surfaces. Brushed finishes complement contemporary designs while staying budget-friendly. Remember that proper finish selection can extend product lifespan by 3-5 years and significantly reduce warranty claims, making the initial investment worthwhile for long-term success.

[External Links Recommendation]

[aluminum housing surface treatment][^1]

[coffee machine corrosion resistance][^2]

[aluminum brushing vs anodizing][^3]

---

[^1]: Discover effective aluminum housing surface treatments that enhance corrosion resistance and longevity.

[^2]: Explore this link to discover materials that enhance the durability and longevity of coffee machines against corrosion.

[^3]: Learn about the pros and cons of each process to make informed decisions for your aluminum projects.