How to Eliminate Die Casting Porosity Using Vacuum Technology and Achieve 98% Yield Rates?

How to Eliminate Die Casting Porosity Using Vacuum Technology and Achieve 98% Yield Rates?

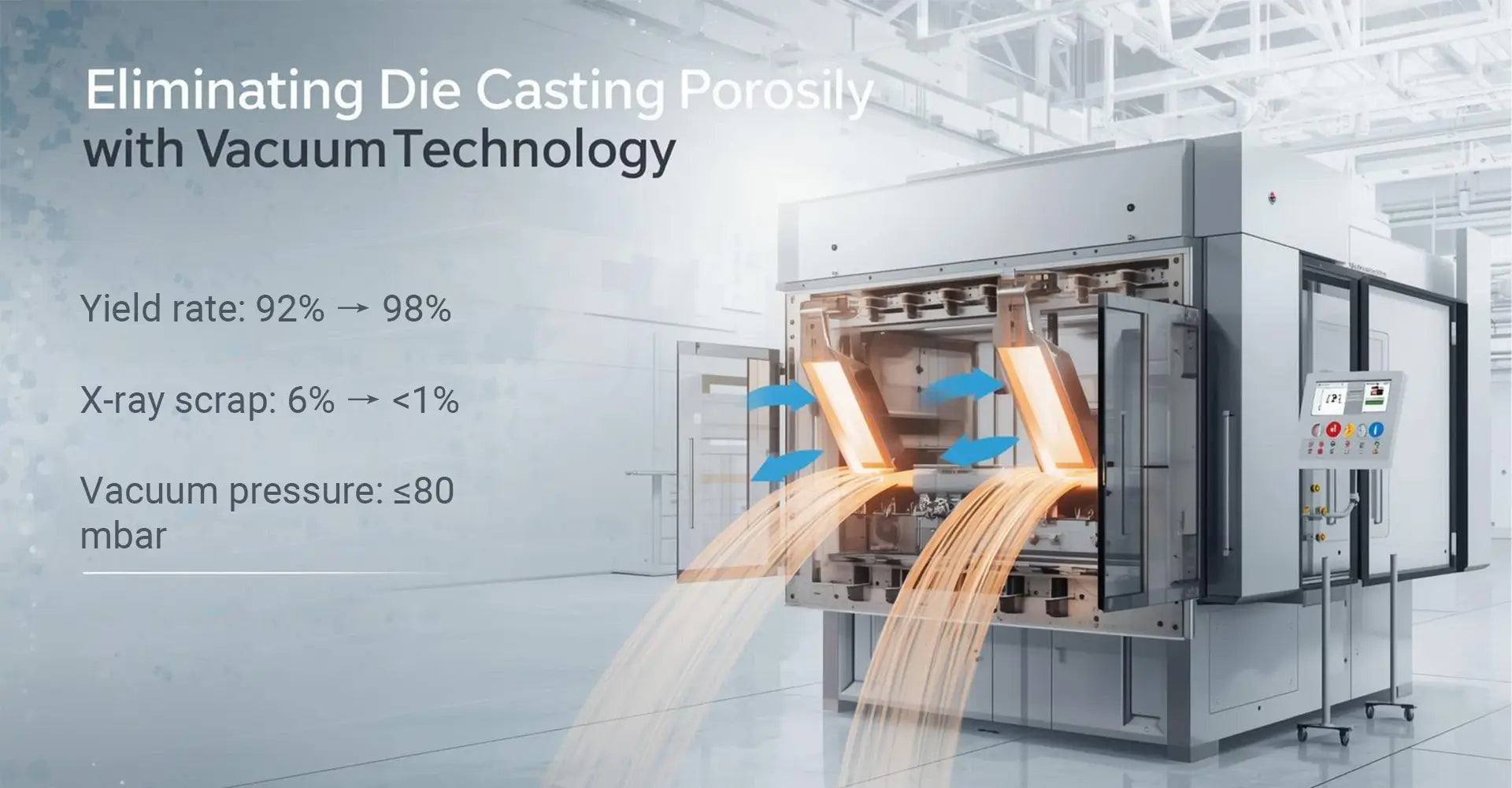

Die casting porosity remains the leading cause of part rejection in aluminum manufacturing, with traditional methods achieving only 92% yield rates. However, vacuum assisted die casting combined with strategic mold venting can push yields to 98% while reducing X-ray scrap rates from 6% to below 1%. This comprehensive guide reveals the exact vacuum pressure parameters (≤80 mbar), timing sequences, and mold design strategies that top manufacturers use to eliminate gas defects completely.

Quick Answer: Achieving porosity-free aluminum die castings requires maintaining vacuum pressure ≤80 mbar in die cavity before metal injection, combined with properly sized vents (0.5mm width) positioned at last-fill areas. Shot sleeve vacuum systems pulling <50 mbar within 0.12 seconds, paired with strategic overflow vents, can eliminate 99.9% of air entrapment issues.

While many foundries struggle with porosity defects that compromise part integrity and increase scrap costs, the solution lies in understanding the science behind gas entrapment and implementing proven vacuum technologies. Let's explore each critical component that transforms problematic casting operations into reliable, high-yield production systems.

Table of Contents

- Why Traditional Venting Methods Fail to Prevent Gas Entrapment?

- What Vacuum Pressure Parameters Eliminate 99.9% of Air Removal Issues?

- How Does Strategic Mold Venting Design Channel Air Out Successfully?

- Which Real-World Results Show 92% to 98% Yield Improvements?

Why Traditional Venting Methods Fail to Prevent Gas Entrapment?

Traditional die casting relies solely on passive venting through parting line gaps and small vent channels to evacuate air during metal injection. Unfortunately, these conventional methods face fundamental limitations when dealing with thin-wall aluminum castings and complex geometries where air becomes trapped in dead zones.

Key Issue: Standard venting cannot evacuate air fast enough (requires ≤0.15 seconds) from complex cavities, leading to gas porosity formation when molten aluminum traps remaining air pockets. This results in visible blowholes and structural weaknesses that cause 6% average scrap rates.

The root problem stems from inadequate air evacuation speed and limited vent placement options. When molten aluminum enters the die cavity at injection speeds around 0.45 m/s, air must escape through narrow vent channels typically 0.5mm wide. However, complex geometries create turbulence that folds aluminum oxide skin, trapping air bubbles that solidify into permanent voids. Additionally, traditional venting cannot address air compression in shot sleeves, where initial air volume gets compressed but not removed, later expanding into porosity defects during solidification. This comprehensive die casting porosity elimination guide addresses these fundamental limitations through proven vacuum technologies.

What Vacuum Pressure Parameters Eliminate 99.9% of Air Removal Issues?

Vacuum-assisted die casting achieves superior results by actively removing air before and during metal injection, rather than relying on passive displacement. The key lies in reaching specific vacuum pressure thresholds within precise timing windows to prevent gas entrapment.

Target Parameters: Die cavity vacuum ≤80 mbar before metal arrival, combined with shot sleeve vacuum <50 mbar achieved within 0.12 seconds of valve opening. These parameters enable 99.9% air removal and reduce porosity levels from >0.5% to <0.3% in critical structural parts.

Successful vacuum implementation requires coordinated shot sleeve vacuum (SSV) and die cavity vacuum (DCV) systems. The SSV system uses a 400 m³/h capacity vacuum pump with 80L buffer tank to rapidly evacuate air from the shot sleeve before plunger movement. Meanwhile, DCV removes remaining air through strategically placed vacuum pins connected to the cavity. Fast-acting plunger tip valves opening in 60ms prevent molten metal from entering vacuum lines. Furthermore, leak-tight sealing using nitrile O-rings maintains leak rates <0.05 mbar L s⁻¹, ensuring consistent vacuum performance across production cycles. These precise vacuum pressure parameters work synergistically with surface finish quality requirements to produce defect-free components.

How Does Strategic Mold Venting Design Channel Air Out Successfully?

Even with vacuum assistance, proper mold venting design remains critical for channeling air efficiently to evacuation points. Strategic vent placement and sizing work synergistically with vacuum systems to create multiple escape paths for trapped air.

Design Strategy: Position vents at last-fill areas identified through flow simulation software, with total vent cross-sectional area sized for ≤0.15 second air evacuation time. Combine peripheral vent slots (0.5mm width), overflow vents, and porous metal vents in complex cores for comprehensive air removal.

Topology-based venting strategies use computational fluid dynamics to predict air trap locations and position vents accordingly. Critical vent placement includes parting line positions, weld line intersections, and deep rib terminations where air naturally accumulates. Therefore, vent sizing calculations consider both depth (typically 0.5mm for aluminum) and total open area requirements based on cavity volume and fill time. Overflow vents serve dual purposes by providing additional air escape routes while capturing initial turbulent metal flow that may contain oxide inclusions. Moreover, this systematic mold venting optimization approach prevents vent clogging through regular maintenance schedules, which can quickly compromise air evacuation performance and return porosity levels to problematic ranges. These techniques prove especially valuable for industrial machinery components requiring zero-defect tolerances.

Which Real-World Results Show 92% to 98% Yield Improvements?

Industry case studies demonstrate measurable improvements when vacuum-assisted die casting combines with strategic venting design. Electric vehicle battery housing production provides compelling evidence of yield improvements and cost savings achieved through porosity elimination.

Case Study Results: EV battery housing production increased from 92% to 98% yield rates while eliminating secondary resin impregnation processes. X-ray scrap rates dropped from 6% to <1%, with fatigue life improvements of 25% in AlSi10Mg alloy components measuring <0.3% porosity via CT scanning.

The EV battery housing project involved 3000-ton press operations producing thin-wall aluminum enclosures requiring zero leak performance. Initially, production suffered from 6% X-ray rejection rates due to microporosity that compromised sealing integrity. Implementation of combined vacuum systems (SSV + DCV) with redesigned venting topology reduced porosity below 0.3% threshold measured by CT scan porosity detection methods. Additionally, these aluminum die casting defects were virtually eliminated through systematic porosity reduction strategies. Financial benefits included eliminated impregnation costs ($2.50 per part), reduced scrap material losses, and improved production scheduling due to consistent quality. The investment in vacuum equipment showed ROI within 11 months, primarily driven by scrap reduction and elimination of secondary processing steps that previously added 24 hours to production cycles. Consequently, this approach proves particularly effective for die casting leak prevention in applications requiring hermetic sealing, similar to precision requirements found in investment casting applications.

Conclusion

Eliminating die casting porosity requires a systematic approach combining vacuum technology with strategic mold design rather than relying on traditional venting alone. By maintaining die cavity vacuum pressure ≤80 mbar, implementing shot sleeve vacuum systems achieving <50 mbar within 0.12 seconds, and positioning vents at last-fill areas with adequate cross-sectional area, foundries can achieve 98% yield rates while reducing X-ray scrap from 6% to below 1%. The investment in vacuum-assisted systems typically pays back within one year through eliminated scrap costs and removed secondary processing requirements, making this technology accessible even for smaller foundries seeking to improve part quality and production reliability.

[External Links Recommendation]

[die casting porosity elimination guide][^1]

[vacuum assisted die casting][^2]

[aluminum die casting defects][^3]

[mold venting optimization][^4]

---

[^1]: Explore this resource to learn effective techniques for eliminating porosity in die casting, ensuring high-quality production.

[^2]: Discover how vacuum assisted die casting can enhance the quality of your products by reducing defects and improving material flow.

[^3]: Understanding these defects can help improve your casting quality and reduce waste.

[^4]: Exploring this can enhance your production efficiency and product quality.