How Does Each Coffee Machine Structure Define CNC Machining Precision Requirements?

How Does Each Coffee Machine Structure Define CNC Machining Precision Requirements?

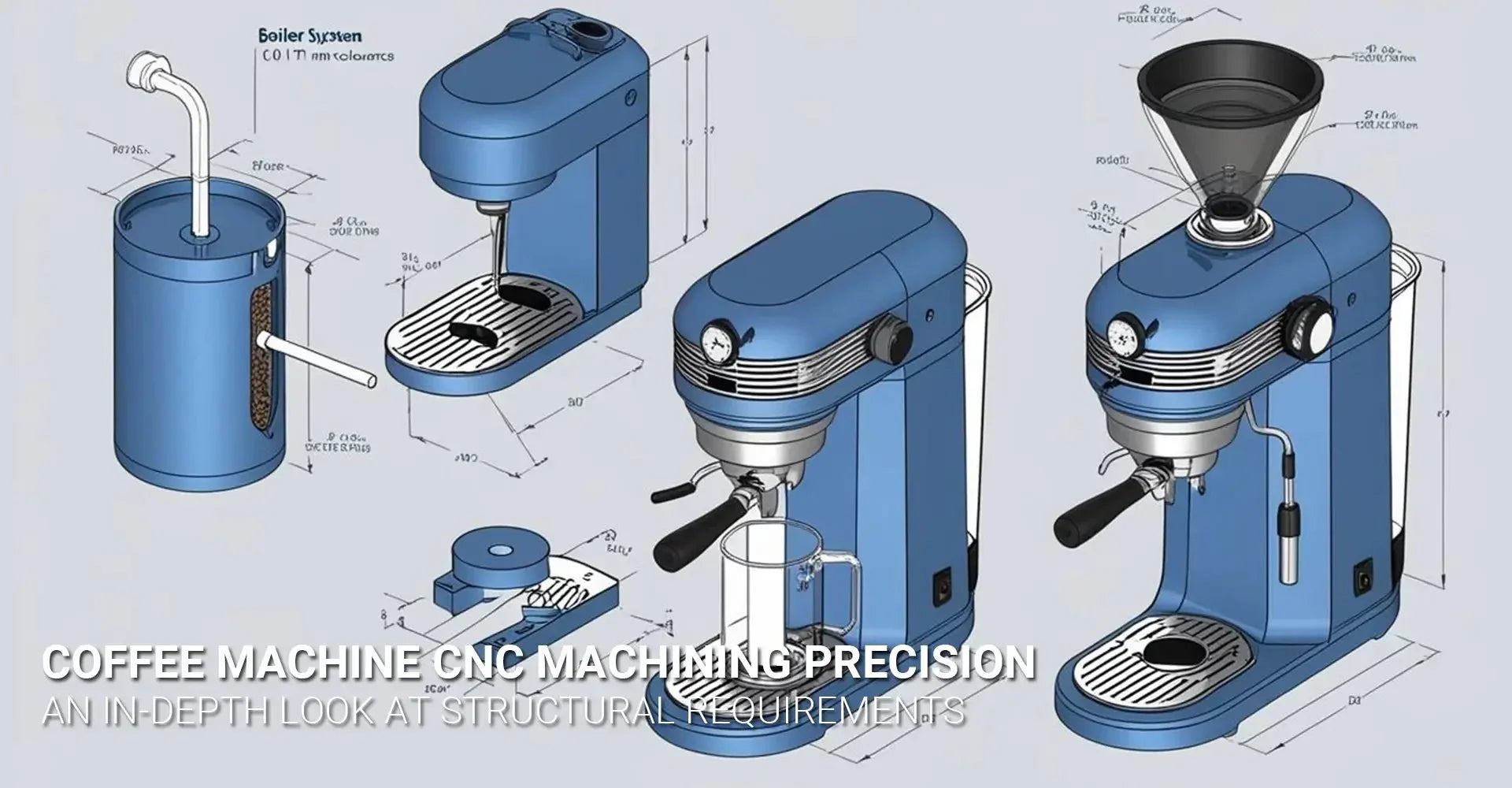

In the world of premium coffee equipment manufacturing, precision is not just a preference – it's an absolute necessity. The relationship between coffee machine structures and CNC machining precision requirements defines the quality, durability, and performance of every unit produced. Modern coffee machines demand extremely tight tolerances and exceptional surface finishes that only precise CNC machining services can deliver.

The integration of advanced manufacturing technologies has revolutionized how we approach coffee equipment production, particularly in maintaining consistent quality across different structural components. Each element of a coffee machine's architecture presents unique challenges that must be met with specific precision requirements.

As we delve deeper into this technical exploration, we'll examine how different structural components demand varying levels of precision in CNC machining, and why these requirements are crucial for optimal performance.

[Table of Contents]

- Why Is Structural Analysis Essential for Coffee Machine CNC Precision?

- What Are the Core Precision Requirements for Brewing System Components?

- How Do Grinding Mechanism Structures Determine Machining Standards?

- What Makes Pressure System Components Demand Ultra-Precise Machining?

Why Is Structural Analysis Essential for Coffee Machine CNC Precision?

Understanding the structural demands of coffee machines is fundamental to achieving optimal CNC machining precision. Each component's role in the overall structure directly influences the required manufacturing tolerances and surface finish specifications.

The correlation between structural integrity and precision machining becomes evident when examining how components interact. For instance, the boiler housing must maintain tolerances of ±0.05 mm to ensure proper thermal expansion without compromising seal integrity.

Modern CNC machining processes must account for various structural factors:

- Material thermal properties affecting component fit

- Load-bearing requirements influencing tolerance specifications

- Assembly interface precision needs

- Vibration resistance requirements

What Are the Core Precision Requirements for Brewing System Components?

The brewing system represents the heart of any coffee machine, where precision directly impacts extraction quality. These components require some of the tightest tolerances in the entire assembly due to their critical role in the brewing process.

Key precision requirements for brewing components include:

- Boiler walls: ±0.1 mm tolerance for optimal heat distribution

- Group head channels: Surface roughness Ra 0.4 μm for consistent water flow

- Temperature sensor housing: ±0.05 mm for accurate readings

- Water distribution plate: ±0.02 mm flatness for even water dispersion

- Shower screen mounting points: ±0.03 mm concentricity

When manufacturing these critical components, specialized CNC machining techniques ensure:

- Perfect sealing surfaces through precision surface finishing

- Consistent water flow paths with controlled channel geometry

- Precise thermal transfer points for temperature stability

- Optimal material thickness for heat retention

- Accurate threading for component assembly

The brewing system's precision requirements extend to several subsystems:

- Water Distribution System

- Channel diameter consistency: ±0.05 mm

- Surface finish: Ra 0.4-0.8 μm

- Port alignment: ±0.02 mm

- Thread precision: Class 6g/6h fit

- Temperature Control System

- Sensor pocket depth: ±0.1 mm

- Heat exchanger wall thickness: ±0.15 mm

- Thermal barrier gaps: ±0.05 mm

- Pressure Management

- Over-pressure valve seats: ±0.01 mm

- Pressure relief channels: ±0.03 mm

- Seal groove precision: ±0.02 mm

How Do Grinding Mechanism Structures Determine Machining Standards?

The grinding mechanism's precision requirements are perhaps the most demanding in coffee equipment manufacturing. These components directly affect grind consistency and, ultimately, extraction quality.

Critical specifications include:

- Burr carrier concentricity: ±0.02 mm

- Housing perpendicularity: ±0.01 mm

- Bearing seat roundness: ±0.005 mm

- Motor shaft alignment: ±0.01 mm

- Adjustment mechanism threads: Class 4 fit

The relationship between structural design and machining precision becomes particularly evident in:

- Burr Mounting System

- Carrier flatness: ±0.015 mm

- Mounting surface parallelism: ±0.01 mm

- Central shaft concentricity: ±0.008 mm

- Retention mechanism precision: ±0.02 mm

- Adjustment Mechanism

- Thread pitch accuracy: ±0.01 mm

- Stepped adjustment points: ±0.02 mm

- Lock ring tolerances: ±0.015 mm

- Reference surface flatness: ±0.01 mm

- Drive System Interface

- Motor mount concentricity: ±0.02 mm

- Shaft coupling alignment: ±0.01 mm

- Bearing pocket roundness: ±0.005 mm

- Cooling channel consistency: ±0.05 mm

What Makes Pressure System Components Demand Ultra-Precise Machining?

Pressure system components require exceptional precision to maintain consistent pressure levels and prevent leaks. These components face both high pressure and temperature variations, making precision crucial for safety and performance.

Manufacturing specifications typically include:

- Pump housing tolerance: ±0.03 mm

- Valve seat surface finish: Ra 0.2 μm

- Steam wand pivot points: ±0.02 mm roundness

- Pressure regulator components: ±0.01 mm

- High-pressure seal surfaces: Ra 0.4 μm maximum

CNC machining expertise ensures precision across various subsystems:

- Pump Assembly Components

- Piston bore roundness: ±0.005 mm

- Cylinder wall straightness: ±0.01 mm

- Valve seat concentricity: ±0.015 mm

- Bearing journal tolerance: ±0.008 mm

- Shaft seal surface finish: Ra 0.2 μm

- Steam System

- Boiler connection ports: ±0.02 mm

- Steam valve seats: ±0.01 mm

- Wand pivot bearings: ±0.015 mm

- Temperature sensor fittings: ±0.03 mm

- Safety valve components: ±0.02 mm

- Pressure Regulation System

- Regulator body tolerance: ±0.02 mm

- Spring cavity dimensions: ±0.03 mm

- Diaphragm seat flatness: ±0.01 mm

- Calibration thread precision: Class 5 fit

- Pressure sensor mounting: ±0.02 mm

Conclusion

The structural complexity of modern coffee machines demands a sophisticated approach to CNC machining precision. Each component's requirements must be carefully considered and maintained throughout the manufacturing process.

Key takeaways:

- Structural analysis guides precision requirements

- Different components demand varying tolerance levels

- Material selection impacts achievable precision

- Quality control must be integrated at every stage

[External Links Recommendation]

[Precision Requirements for Brewing System Components](https://www.craftmasterstainless.com/blog/2023/7/13/the-essential-components-of-a-brewery-system)[^1]

[CNC machining precision](https://www.rapiddirect.com/blog/cnc-precision-machining/)[^2]

[Ultra-Precise Machining](https://www.boyiprototyping.com/cnc-machining-guide/ultra-precision-machining/)[^3]

---

[^1]: Learning about precision requirements can help in selecting the right components for optimal brewing performance.

[^2]: Understanding CNC machining precision is crucial for ensuring high-quality manufacturing processes, especially in industries like brewing.

[^3]: Exploring ultra-precise machining can reveal its advantages in achieving superior quality and efficiency in production.

-

Posted in

Precision Machining