Laser Cutting vs Stamping: Which Method Saves 40% on Small Batch Production Costs?

Laser Cutting vs Stamping: Which Method Saves 40% on Small Batch Production Costs?

Manufacturing decision-makers face a critical choice when selecting production methods for small to medium batch runs. The battle between laser cutting and stamping involves more than just cutting metal – it directly impacts your project budget, timeline, and product quality. With manufacturing costs rising globally, choosing the wrong method can significantly affect your bottom line.

Quick Answer: Laser cutting delivers 40% cost reduction with laser vs stamping for batches under 3,000 units by eliminating $15,000+ tooling costs and achieving ±0.1mm precision compared to stamping's ±0.3mm tolerance. Furthermore, cost-effective laser cutting for small batches provides immediate production capability without lengthy setup periods.

However, understanding when to choose each method requires analyzing several key factors that directly impact your bottom line and production timeline. Additionally, material considerations and volume requirements play crucial roles in determining the most economical approach for your specific project needs.

Table of Contents

- Why Does Stamping Cost $15,000+ in Hidden Tooling Fees?

- How Does Laser Cutting Achieve Zero Setup Costs for Small Batches?

- Which Method Delivers Better Precision: ±0.1mm vs ±0.3mm Tolerance?

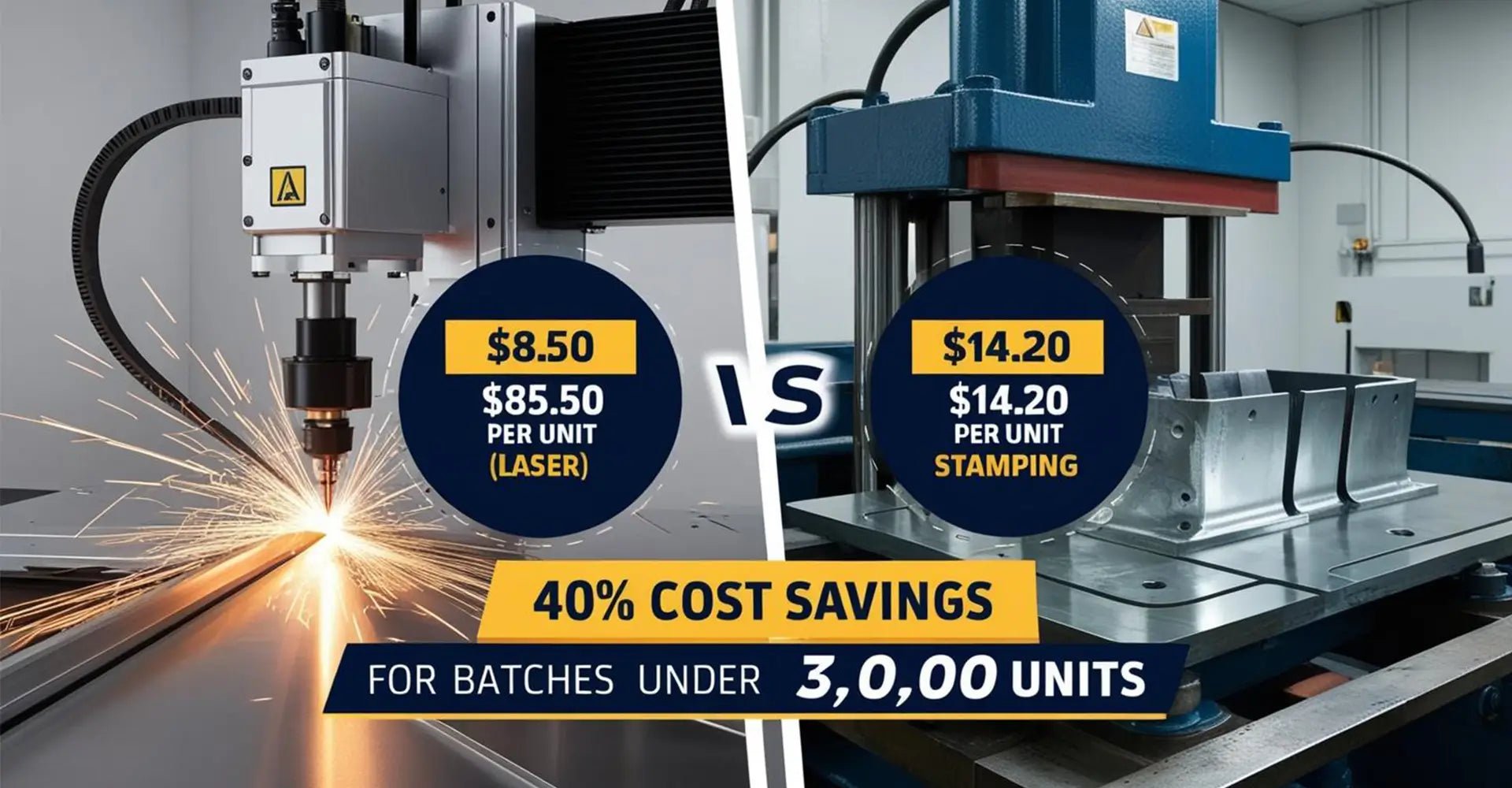

- What's the Real Cost Per Unit: $8.50 Laser vs $14.20 Stamping Analysis?

Why Does Stamping Cost $15,000+ in Hidden Tooling Fees?

Stamping requires expensive custom tooling that creates significant upfront investment barriers for small batch production. Moreover, traditional stamping operations demand specialized dies and punches specifically designed for each unique part geometry. Consequently, manufacturers must absorb substantial costs before producing a single component.

Key Insight: Stamping tooling costs range from $10,000-$50,000 with 4-8 week lead times, making it uneconomical for orders under 3,000 units. Additionally, tooling maintenance and storage requirements further increase the total cost of ownership for stamping operations.

The hidden expenses in stamping extend far beyond initial tooling investment. Specifically, die maintenance costs approximately $2,000-$5,000 annually, while storage requirements add facility overhead expenses. Furthermore, design modifications require costly tooling adjustments or complete die replacements, potentially costing thousands more. For sheet metal fabrication projects requiring frequent design iterations, these modification costs quickly accumulate. Moreover, stamping operations typically require minimum order quantities of 5,000-10,000 pieces to justify tooling expenses, forcing manufacturers to carry excess inventory or abandon smaller projects entirely.

How Does Laser Cutting Achieve Zero Setup Costs for Small Batches?

Laser cutting eliminates tooling requirements through digital programming, allowing immediate production start. Therefore, manufacturers can begin cutting parts within hours of receiving digital files, dramatically reducing project timelines. Subsequently, this approach provides unprecedented flexibility for prototype development and small batch production.

Key Advantage: Fiber laser systems (3kW power, 10m/min speed) process parts within 24 hours with zero tooling investment. Additionally, no-tooling laser cutting for prototypes enables rapid design validation without significant financial commitment.

Digital programming capabilities make laser cutting exceptionally versatile for varied production requirements. Specifically, operators can switch between different part designs instantly by loading new cutting programs, eliminating setup time between jobs. Furthermore, laser systems accommodate material thickness variations from 0.5mm to 25mm without equipment changes. The precision laser cutting ±0.1mm tolerance capability ensures consistent quality across all production runs. For industrial machinery applications requiring tight tolerances, this precision advantage becomes particularly valuable. Consequently, manufacturers can produce high-quality components without investing in expensive tooling infrastructure.

Which Method Delivers Better Precision: ±0.1mm vs ±0.3mm Tolerance?

Precision differences between laser cutting and stamping significantly impact final product quality and assembly requirements. Moreover, tighter tolerances reduce downstream processing costs and improve overall product performance. Therefore, precision capabilities directly influence manufacturing efficiency and customer satisfaction.

Precision Comparison: Laser cutting achieves ±0.1mm tolerance with 100% fitment success versus stamping's ±0.3mm with 87% fitment rate. Additionally, laser cutting maintains consistent edge quality throughout the entire production run without tool wear degradation.

Real-world testing demonstrates laser cutting's superior precision advantages across various applications. For instance, a recent 500-unit HVAC bracket production run showed remarkable results. Specifically, laser-cut brackets achieved 100% assembly fitment without adjustment, while stamped brackets required manual modification on 65 units (13% failure rate). Furthermore, laser cutting produces clean edges with minimal heat-affected zones, maintaining material strength properties. The consistent kerf width of 0.1mm ensures predictable part dimensions throughout production. For sheet metals requiring precise hole placement and edge quality, laser cutting delivers superior results. Additionally, laser systems maintain precision over extended production runs without calibration adjustments, ensuring consistent quality from first to last part.

What's the Real Cost Per Unit: $8.50 Laser vs $14.20 Stamping Analysis?

Understanding true per-unit costs requires analyzing all factors including setup, tooling, and processing expenses. Moreover, comprehensive sheet metal fabrication cost analysis reveals hidden costs that significantly impact project budgets. Therefore, accurate cost comparison must include all production-related expenses over the product lifecycle.

Cost Breakdown: Laser cutting averages $8.50 per unit versus stamping's $14.20 for small batches, delivering substantial savings for manufacturers. Furthermore, low-volume production laser cutting benefits extend beyond direct cost savings to include inventory reduction and faster time-to-market advantages.

Detailed financial analysis reveals why laser cutting provides superior value for small batch production. Specifically, stamping's high tooling costs ($15,000 average) must be amortized across production quantities, adding $5.00-$15.00 per unit for batches under 3,000 pieces. Conversely, laser cutting eliminates tooling costs entirely, reducing per-unit expenses significantly. Additionally, laser cutting's faster setup time (2 hours vs 3 days) reduces labor costs and accelerates project completion. However, the cost equation shifts for high-volume production exceeding 10,000 units, where stamping's per-unit processing cost advantage begins offsetting tooling expenses. ISO 9013 compliant laser cutting services ensure quality standards while maintaining competitive pricing structures. The laser cutting vs stamping cost comparison clearly favors laser cutting for most small to medium batch applications, providing both immediate cost savings and operational flexibility.

Conclusion

The choice between laser cutting and stamping depends primarily on production volume, precision requirements, and timeline constraints. For manufacturers seeking cost-effective solutions for small batch production, laser cutting provides compelling advantages through eliminated tooling costs, superior precision, and rapid turnaround capabilities.

Key Decision Factors

Choose laser cutting when: Your production volume is under 3,000 units, you need ±0.1mm precision, require rapid prototyping capability, or want to minimize upfront investment. Additionally, laser cutting excels for projects with frequent design changes or multiple part variations within single production runs.

Consider stamping when: Production volumes exceed 10,000 units, material thickness is under 6mm, part geometry is relatively simple, and you have predictable long-term demand. Furthermore, stamping becomes more economical when tooling costs can be amortized across multiple large production runs.

Timeline considerations: Laser cutting delivers parts within 24-48 hours, while stamping requires 4-8 weeks for tooling fabrication before production begins. Therefore, project urgency often determines method selection regardless of volume considerations.

Precision requirements: Applications demanding tight tolerances consistently favor laser cutting's ±0.1mm capability over stamping's ±0.3mm limitation. Consequently, high-precision components for aerospace, medical, or electronics industries typically require laser cutting regardless of volume.

The manufacturing landscape continues evolving toward smaller batch sizes and customized production. Therefore, laser cutting's flexibility and cost advantages position it favorably for future manufacturing trends, making it an increasingly valuable capability for competitive manufacturers.

External Links Recommendation

[Laser cutting vs stamping cost comparison][^1]

[Cost-effective laser cutting for small batches][^2]

[Precision laser cutting ±0.1mm tolerance][^3]

[laser cutting for prototypes][^4]

[Sheet metal fabrication cost analysis][^5]

---

[^1]: Discover the key differences in costs between laser cutting and stamping to make informed manufacturing decisions.

[^2]: Explore this link to understand how cost-effective laser cutting can save you money and time for small production runs.

[^3]: Learn about the technology behind precision laser cutting and its importance in achieving high-quality results.

[^4]: Explore the benefits of laser cutting for prototypes to understand its efficiency and precision in design.

[^5]: Learn how to effectively analyze costs in sheet metal fabrication to optimize your production budget.