How Do CMM Inspection Standards Achieve ±0.05mm Position Tolerance While Maintaining Sub-0.1mm Flatness Verification?

How Do CMM Inspection Standards Achieve ±0.05mm Position Tolerance While Maintaining Sub-0.1mm Flatness Verification?

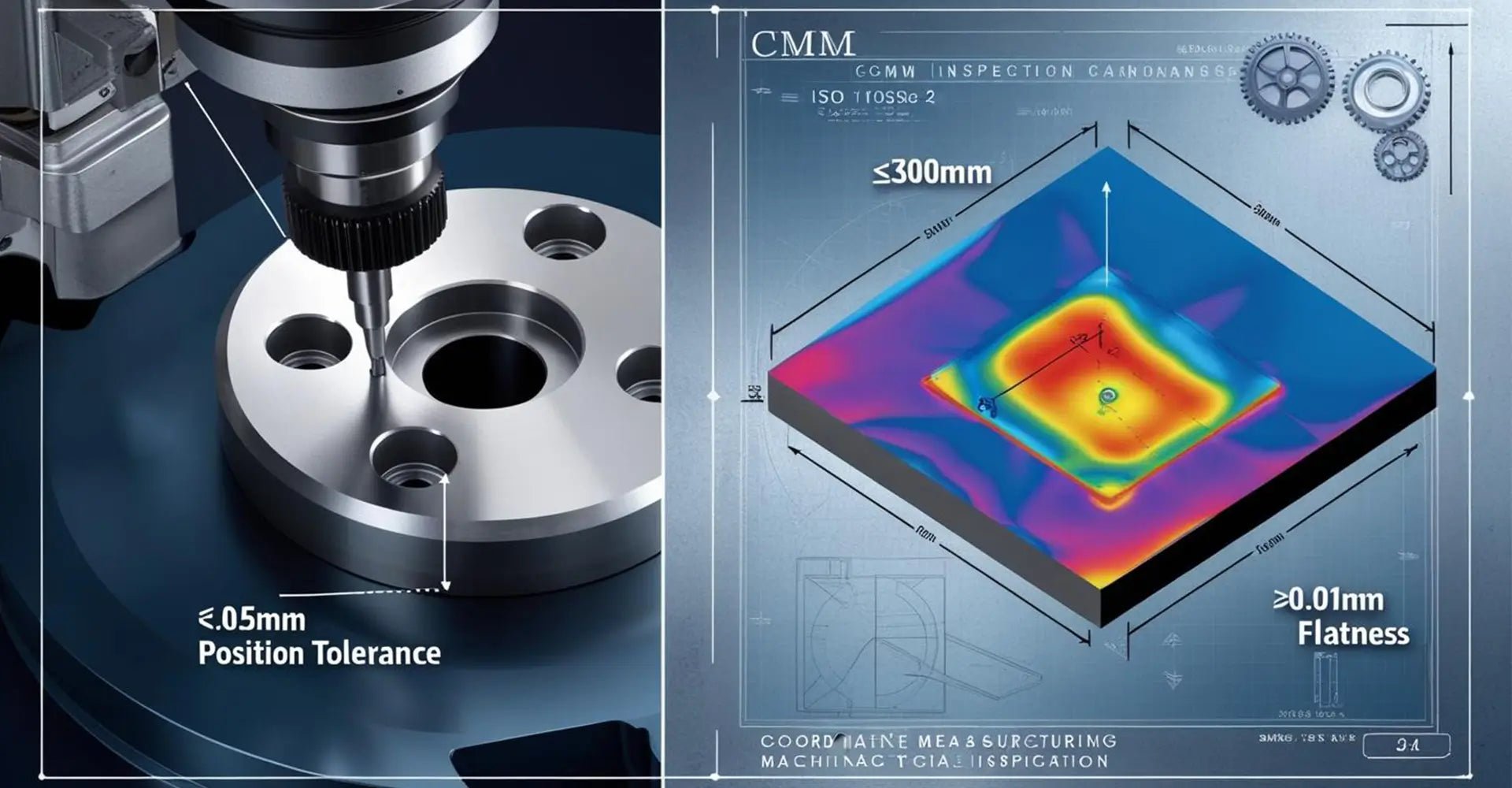

Quality engineers and manufacturing managers face mounting pressure to deliver precision parts while controlling inspection costs. Meanwhile, achieving ±0.05mm hole position tolerance and ≤0.1mm flatness measurements has become standard practice across aerospace, automotive, and medical device industries. Therefore, understanding proper CMM inspection standards for critical dimensions enables manufacturers to meet stringent quality requirements without exceeding budget constraints.

Key Tolerance Achievement Stats:

- Position Accuracy: ±0.05mm repeatability with proper probe selection

- Flatness Verification: Sub-0.1mm measurement across surfaces up to 300x300mm

- Cost Control: 5% inspection budget allocation maximizes ROI

- Time Savings: Automated programming reduces measurement time by 73% (45min → 12min/part)

Understanding these critical dimension standards requires examining four core areas: cost-effective measurement strategies, position tolerance techniques, flatness verification methods, and real-world implementation cases. Therefore, let's explore each component that enables consistent CMM performance while maintaining competitive manufacturing costs.

Table of Contents

- What Cost-Effective Strategies Keep CMM Inspection Under 5% of Total Manufacturing Budget?

- How Can You Achieve Consistent ±0.05mm Hole Position Tolerance with CMM Systems?

- Which Techniques Deliver Sub-0.1mm Flatness Verification Across Large Surfaces?

-

What Real-World Results Show 32% Cost Reduction in Automotive CMM Applications?

What Cost-Effective Strategies Keep CMM Inspection Under 5% of Total Manufacturing Budget?

Manufacturing managers consistently struggle with balancing quality assurance costs against production efficiency. However, implementing strategic CMM inspection approaches can maintain costs below 5% while achieving 90% defect detection rates. Furthermore, manufacturers utilizing professional CNC machining services understand that proper inspection planning prevents costly rework and customer returns.

Cost Control Key Points:

- Budget Allocation: 4-7% inspection costs for batches of 50-500 units

- Detection Rate: 90% defect identification vs 12% savings from manual checks

- ROI Calculation: Automated systems pay back investment within 18 months

- Setup Time: Modular fixtures reduce programming time by 60%

Smart manufacturers implement modular fixture systems that accommodate multiple part families. Additionally, reusable CMM programs eliminate repetitive setup tasks through systematic programming approaches. Furthermore, temperature-controlled environments (±1°C) ensure measurement reliability without costly re-inspections. Most importantly, automated pallet systems enable lights-out operation, maximizing machine utilization while minimizing labor costs. Companies implementing 5% inspection cost optimization strategies consistently outperform competitors who rely on manual measurement methods.

How Can You Achieve Consistent ±0.05mm Hole Position Tolerance with CMM Systems?

Hole position accuracy depends on several critical factors including probe selection, measurement point density, and environmental controls. Moreover, understanding these variables enables consistent ±0.05mm repeatability across production runs. Similarly, manufacturers working with precision metals and plastics require reliable Coordinate Measuring Machine tolerance verification to meet customer specifications.

Position Tolerance Essentials:

- Probe Selection: 2mm ruby tips for small holes, 3mm ceramic for durability

- Point Density: Minimum 8 points per hole for reliable center calculation

- Environmental Control: ±1°C temperature stability prevents thermal drift

- Verification Standard: ISO 10360-2 compliance ensures measurement traceability

Successful position tolerance verification requires systematic probe tip maintenance and calibration schedules. Consequently, weekly gauge block checks prevent gradual measurement drift that could compromise measurement accuracy. Similarly, proper part fixturing eliminates movement during measurement cycles, ensuring repeatable results. Furthermore, CMM software algorithms automatically compensate for probe tip wear when calibrated correctly according to ISO 10360 standards. Implementing ±0.05mm hole position tolerance CMM procedures requires attention to these fundamental setup and maintenance practices.

Which Techniques Deliver Sub-0.1mm Flatness Verification Across Large Surfaces?

Large surface flatness measurement presents unique challenges requiring strategic point sampling and data analysis techniques. Nevertheless, systematic approaches consistently achieve sub-0.1mm verification across surfaces up to 300x300mm. Additionally, components requiring specific surface finish specifications benefit from comprehensive flatness documentation that supports quality certifications.

Flatness Measurement Framework:

- Grid Pattern: 10x10mm spacing for comprehensive surface mapping

- Data Points: 30,000 measurements for 300x300mm surfaces

- Surface Prep: As-machined surfaces acceptable, deburring recommended

- Analysis Method: Least squares plane fitting per ASME Y14.5-2018

Advanced CMM systems utilize adaptive sampling algorithms that increase point density in areas showing greater variation. Therefore, efficient measurement strategies balance comprehensive coverage with reasonable cycle times for optimal productivity. Additionally, proper workpiece support prevents deflection that could compromise flatness readings during measurement cycles. Most significantly, automated reporting generates deviation heatmaps that clearly communicate results to production teams and customers. Successful flatness measurement ≤0.1mm with CMM requires systematic sampling patterns and proper data analysis techniques.

What Real-World Results Show 32% Cost Reduction in Automotive CMM Applications?

A leading automotive bracket supplier implemented comprehensive CMM automation that delivered measurable cost savings while improving quality consistency. Consequently, their success demonstrates practical benefits of strategic coordinate measuring machine implementation. Moreover, manufacturers utilizing advanced industrial machinery achieve similar results through systematic automation and process control integration.

Case Study Results:

- Time Reduction: 45 minutes → 12 minutes per part (73% improvement)

- Cost Savings: 32% reduction in total inspection expenses

- Quality Improvement: Zero customer quality complaints over 12 months

- Throughput Increase: 200% capacity improvement with same staffing

This automotive supplier invested in automated pallet loading systems and developed standardized measurement routines for their bracket family. Furthermore, they implemented statistical process control integration that triggers immediate alerts when measurements approach tolerance limits. Additionally, their quality team established predictive maintenance schedules that prevent measurement system downtime during critical production periods. Most importantly, comprehensive operator training ensured consistent results across all shifts and personnel changes. Their cost-effective CMM measurement solutions approach demonstrates how systematic implementation delivers measurable business results while maintaining strict quality standards.

Conclusion

The Contents of Conclusion

Achieving ±0.05mm position tolerance and sub-0.1mm flatness verification through coordinate measuring machines requires systematic implementation of proven techniques. Moreover, maintaining inspection costs below 5% of manufacturing budget becomes achievable through strategic automation and process control. Additionally, implementing comprehensive CNC Quality Control procedures ensures consistent part quality while maximizing production efficiency.

Key success factors include proper environmental controls, appropriate probe selection, comprehensive measurement planning, and automated reporting systems. Furthermore, real-world case studies demonstrate that manufacturers can simultaneously improve quality and reduce costs through systematic CMM implementation strategies.

Quality engineers should focus on ISO 10360 compliance, ASME Y14.5 standard adherence, and continuous measurement system validation. Therefore, implementing these coordinate measuring machine strategies enables consistent critical dimension verification while maintaining competitive manufacturing costs. Most importantly, successful CMM programs balance precision requirements with practical cost considerations that support long-term business sustainability.

External Links Recommendation

[CMM inspection standards for critical dimensions][^1]

[Coordinate Measuring Machine tolerance verification][^2]

[Cost-effective CMM measurement solutions][^3]

[±0.05mm hole position tolerance CMM][^4]

[ISO 10360 CMM performance verification][^5]

[ASME Y14.5 GD&T compliance for CMM][^6]

---

[^1]: Understanding CMM inspection standards is crucial for ensuring precision in manufacturing. Explore this link to enhance your knowledge.

[^2]: Learn about the processes involved in CMM tolerance verification to improve quality control in your projects.

[^3]: Discover affordable CMM measurement solutions that can optimize your operations without compromising quality.

[^4]: Understanding this tolerance is crucial for precision engineering and quality control in manufacturing processes.

[^5]: Exploring ISO 10360 standards can enhance your knowledge of CMM accuracy and reliability, essential for quality assurance.

[^6]: Learning about GD&T compliance is vital for ensuring that your CMM measurements meet industry standards and specifications.

phontechm