How Can You Machine H13 Die Molds Without Destroying Your Tools and Budget?

Are you burning through cutting tools faster than you can replace them? Many machinists face this exact challenge when working with H13 tool steel for die molds. This hot-work steel is known for its toughness and heat resistance, which makes it perfect for die casting applications. However, these same properties can quickly turn your machining project into a costly nightmare. Poor tool selection, incorrect feeds and speeds, and inadequate heat management lead to rapid tool wear, poor surface quality, and ultimately shorter mold service life. Fortunately, by understanding H13's unique characteristics and applying proven machining strategies, you can dramatically reduce costs while producing superior quality molds.

Quick Answer: Essential H13 Die Mold CNC Milling Parameters

Need immediate guidance? Here's what works:

| Parameter | Recommended Value |

|---|---|

| Cutting Speed | 450-550 SFM (140-170 m/min) for semi-finishing |

| Feed Rate | 0.0025-0.0035 IPT (0.06-0.09 mm/tooth) |

| Best Coating | AlTiN or AlCrN PVD coatings |

| Axial Depth | 0.020"-0.060" (0.5-1.5 mm) |

| Radial Depth | 25%-40% of cutter diameter |

| Key Strategy | Control heat generation through proper parameters and consistent coolant application |

These starting parameters apply to hardened H13 at 45-48 HRC using a ½" (6mm) 3-flute coated carbide end mill. Always test on your specific setup and adjust based on machine rigidity and toolholder performance.

While these quick parameters provide a solid starting point, truly mastering H13 machining requires a deeper understanding of why this material behaves the way it does. Moreover, selecting the right tooling, coatings, and CNC machining service strategies will separate successful projects from costly failures. In this comprehensive H13 steel machining guide, we'll explore everything from material properties to finishing techniques, giving you the knowledge to produce long-lasting, high-quality die molds while keeping your tooling costs under control.

Table of Contents

- What Makes H13 Steel So Challenging to Machine?

- Which Cutting Tools and Coatings Work Best for H13 Die Molds?

- What Are the Correct Feeds and Speeds for H13 at Different Hardness Levels?

- How Do You Achieve a Mirror Finish on H13 Mold Cavities?

- Conclusion

What Makes H13 Steel So Challenging to Machine?

Opening the H13 Mystery

H13 tool steel presents unique machining challenges that catch even experienced machinists off guard. Unlike softer materials, H13 maintains its hardness even when temperatures soar during cutting operations. This characteristic makes it ideal for hot-work applications like die casting molds. However, this same property creates significant obstacles during the custom CNC milling services process. The material fights back against cutting tools, generating intense heat and causing rapid wear that can quickly escalate your project costs.

Key Challenges at a Glance

The Four Major Obstacles:

- Extreme Heat Generation - Cutting edges reach temperatures exceeding 1000°F

- Rapid Tool Wear - Abrasive carbides in H13 accelerate edge breakdown

- Surface Micro-Cracks - Thermal stress creates white layer damage and fissures

- Work Hardening - The material becomes harder as you cut it

These challenges compound each other. Consequently, using standard machining parameters designed for softer steels will inevitably lead to poor results and wasted resources.

Understanding H13's Composition and Behavior

To effectively machine H13, you first need to understand what makes it so tough. H13 contains approximately 5% chromium, 1.5% molybdenum, and 1% vanadium. These alloying elements create a matrix that resists deformation and maintains hardness at elevated temperatures. Furthermore, the chromium content provides excellent corrosion resistance, while molybdenum enhances strength and toughness. Vanadium forms hard carbides that give H13 its wear resistance but also make it highly abrasive to cutting tools.

During machining, the cutting edge generates tremendous friction. This friction creates heat that would normally soften most steels, making them easier to cut. However, H13's special composition allows it to retain its hardness even at high temperatures. Additionally, when you apply cutting forces, the material immediately ahead of the tool undergoes plastic deformation, which actually hardens it further through a phenomenon called work hardening. This creates a vicious cycle where each pass becomes progressively more difficult.

The thermal conductivity of H13 is relatively low compared to other tool steels. Therefore, heat doesn't dissipate quickly from the cutting zone. Instead, it concentrates at the tool-workpiece interface, rapidly degrading your cutting edge. This is precisely why standard parameters that work for P20 or mild steel fail catastrophically with H13. Without proper heat management through optimized feeds, speeds, and coolant strategies, you'll experience premature tool failure, poor surface integrity, and dimensional inaccuracies that compromise the final mold's performance in industrial machinery applications.

Which Cutting Tools and Coatings Work Best for H13 Die Molds?

Tool Selection: The Foundation of Success

Selecting the right tooling for H13 steel is arguably the most critical decision you'll make. The wrong tool will fail quickly regardless of how well you optimize your parameters. Conversely, the right tool combined with proper techniques will deliver consistent results and extended tool life. When evaluating tooling for H13 steel, you need to consider three primary factors: substrate material, tool geometry, and coating technology. Each element plays a vital role in how effectively your tool handles the extreme conditions of H13 machining.

Your Tool Selection Quick Reference

Essential Tool Specifications:

- Substrate Material: Fine-grain carbide (WC-Co) with 10-12% cobalt binder

- Geometry: Variable helix (unequal spacing) with high-positive rake angles

- Coating: AlTiN or AlCrN PVD (Physical Vapor Deposition) coatings

- Flute Count: 3-4 flutes for roughing operations, 5-6 flutes for finishing

- Corner Radius: 0.005"-0.015" for roughing, sharp for finishing

- Helix Angle: 35-45 degrees for general milling

These specifications aren't arbitrary recommendations. Instead, they're based on how H13 responds to cutting forces and heat generation. Therefore, deviating from these guidelines should only happen when you have specific reasons and understand the trade-offs involved.

Coatings, Geometry, and Performance

Let's explore why H13 milling cutter coatings make such a dramatic difference. PVD coatings like AlTiN (Aluminum Titanium Nitride) form an extremely hard, thin layer on your cutting tool. This layer has a hardness of approximately 3000-3500 HV (Vickers Hardness), which far exceeds H13's hardness of 45-52 HRC. More importantly, AlTiN maintains its hardness even at temperatures exceeding 1500°F. When the cutting edge heats up during machining, the coating creates a protective thermal barrier that prevents heat from transferring into the carbide substrate.

AlCrN (Aluminum Chromium Nitride) represents a newer coating technology that offers even better performance for some applications. It has superior oxidation resistance and maintains hardness at slightly higher temperatures than AlTiN. However, AlCrN typically costs 15-20% more than AlTiN. For most H13 applications, AlTiN provides the best balance of performance and cost-effectiveness.

You should avoid CVD (Chemical Vapor Deposition) coatings for finishing operations on H13. While CVD coatings like TiCN are excellent for some applications, they create a slightly rougher surface on the cutting edge compared to PVD coatings. This micro-roughness can transfer to your workpiece surface, making it difficult to achieve the mirror finishes required for high-quality molds. Additionally, CVD coatings are applied at higher temperatures, which can affect the substrate's mechanical properties.

Tool geometry significantly impacts chip formation and heat dissipation. Variable helix tools with unequal flute spacing help break up harmonic vibrations that cause chatter. This is especially important when machining hardened H13 where tool deflection and vibration can quickly destroy surface finish. High-positive rake angles create a shearing action rather than a crushing action, which generates less heat and requires lower cutting forces. This becomes critically important when working with CNC turning operations or when tool overhang exceeds three times the diameter.

The best cutter for H13 die mold applications combines all these elements. For roughing, choose a 4-flute variable helix end mill with AlTiN coating and a corner radius. The corner radius strengthens the cutting edge and distributes cutting forces over a larger area, reducing the risk of edge chipping. For finishing operations, switch to a sharp-edged tool with 5-6 flutes and either AlTiN or AlCrN coating depending on your surface finish requirements and budget constraints.

What Are the Correct Feeds and Speeds for H13 at Different Hardness Levels?

Why Standard Parameters Fail

Many machinists make the mistake of applying generic "tool steel" parameters to H13, expecting reasonable results. Unfortunately, H13's unique properties demand specifically tailored H13 CNC feeds and speeds. Parameters that work perfectly for softer pre-hardened steels will either cause rapid tool failure or leave excessive heat-affected zones in your mold surface. Conversely, overly conservative parameters extend cycle times unnecessarily and can actually increase tool wear through rubbing rather than cutting. The key is finding the sweet spot where chip load, cutting speed, and depth of cut work together to manage heat while maintaining productivity.

Complete H13 Roughing and Finishing Parameters Library

For Hardened H13 (45-48 HRC):

Roughing Operations:

- Cutting Speed (Vc): 350-450 SFM (105-140 m/min)

- Feed per Tooth (Fz): 0.004-0.006 IPT (0.10-0.15 mm/tooth)

- Axial Depth of Cut (Ap): 0.100"-0.200" (2.5-5.0 mm)

- Radial Depth of Cut (Ae): 50%-75% of cutter diameter

- Coolant Strategy: Flood coolant or high-pressure MQL

Semi-Finishing Operations:

- Cutting Speed (Vc): 450-550 SFM (140-170 m/min)

- Feed per Tooth (Fz): 0.0025-0.0035 IPT (0.06-0.09 mm/tooth)

- Axial Depth of Cut (Ap): 0.020"-0.060" (0.5-1.5 mm)

- Radial Depth of Cut (Ae): 25%-40% of cutter diameter

- Coolant Strategy: Flood coolant preferred

Finishing Operations:

- Cutting Speed (Vc): 500-600 SFM (150-180 m/min)

- Feed per Tooth (Fz): 0.001-0.002 IPT (0.025-0.05 mm/tooth)

- Axial Depth of Cut (Ap): 0.002"-0.010" (0.05-0.25 mm)

- Radial Depth of Cut (Ae): 10%-20% of cutter diameter

- Coolant Strategy: Consistent flood coolant or air blast for dry finishing

Mastering Parameter Adjustments and Troubleshooting

Understanding the baseline parameters is only the first step. Real-world machining requires constant adjustment based on machine capability, toolholder rigidity, material condition, and coolant effectiveness. Therefore, let's explore how to fine-tune these parameters for your specific situation while implementing effective H13 tool wear reduction strategies.

Machine Rigidity Considerations: If your machine tool lacks rigidity or you're working with significant tool overhang (more than 3× diameter), reduce your radial depth of cut by 25-30%. Simultaneously, increase your axial depth of cut proportionally to maintain similar material removal rates. This adjustment reduces side forces that cause deflection and chatter while still maintaining productivity. Additionally, lowering your feed per tooth by 10-15% helps compensate for reduced cutting efficiency.

Coolant Strategy Impact: Your coolant delivery method dramatically affects achievable parameters. Flood coolant with at least 5% concentration provides the best heat management and allows you to use the upper end of recommended speeds. High-pressure MQL (Minimum Quantity Lubrication) works well for roughing but requires 10-15% speed reduction compared to flood coolant. Dry machining should only be attempted for very light finishing passes, and you must reduce speeds by at least 20-25% while increasing feed per tooth slightly to ensure proper chip formation.

Common Troubleshooting Scenarios:

Problem: Rapid tool wear on the cutting edge corners

- Solution: Reduce cutting speed by 50-75 SFM and increase feed per tooth by 0.0005-0.001 IPT. The tool is likely rubbing rather than cutting due to insufficient chip load.

Problem: Chatter marks on the surface

- Solution: Reduce radial engagement to 15-20% of diameter and ensure axial depth is at least 2-3 times the radial engagement. Check toolholder runout (should be under 0.0005").

Problem: Built-up edge (BUE) forming on the cutter

- Solution: Increase cutting speed by 75-100 SFM to get into a higher temperature regime where BUE doesn't form. Verify coolant concentration and flow rate.

Problem: Poor surface finish with visible feed marks

- Solution: Reduce feed per tooth by 25-30% and ensure you're using a finishing tool with 5-6 flutes. Consider increasing spindle speed if thermal conditions allow.

Problem: Tool breaking unexpectedly

- Solution: This usually indicates excessive side load. Reduce radial engagement immediately and check for deflection. Verify that your actual hardness matches expected values (measure with a portable hardness tester).

When implementing these parameters on projects requiring precision custom CNC milling services, always start at the conservative end of the ranges. Subsequently, increase speeds and feeds gradually while monitoring tool wear, surface finish, and part temperature. Keep detailed records of what works for your specific setup, as every machine, toolholder, and material batch can behave slightly differently. This systematic approach to extending H13 mold life through optimized machining will pay dividends in both quality and cost savings over time.

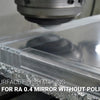

How Do You Achieve a Mirror Finish on H13 Mold Cavities?

The Surface Finish Challenge

Achieving exceptional H13 machining surface finish represents the pinnacle of precision machining. Mold cavities require mirror-like surfaces not just for aesthetics, but for functional reasons. Surface imperfections become stress concentration points where cracks initiate under the cyclic thermal loading of production. Additionally, rough surfaces increase friction during part ejection and can transfer defects to cast components. Many machinists struggle with H13 finishing because the same hardness that makes it durable also makes it unforgiving during final passes. Even minor tool wear, inconsistent parameters, or poor toolpath strategy will leave visible marks that require extensive hand polishing or EDM refinement.

Your 5-Step Checklist for Perfect H13 Surface Finish

Follow these steps systematically for superior results:

-

Select Sharp, Dedicated Finishing Tools - Use a new or freshly sharpened end mill with fine-grain carbide substrate specifically designed for finishing operations, never a tool that's already been used for roughing.

-

Implement High-Positive Rake Geometry - Choose tools with rake angles of 12-15 degrees to create a shearing cut that slices through material rather than crushing it, generating less heat and pressure.

-

Apply Ultra-Light Finishing Passes - Limit your axial depth of cut to 0.002" (0.05mm) maximum per pass, even if this requires additional passes to reach final depth.

-

Use Constant Step-Over Toolpaths - Program your CAM software to maintain uniform step-over distances throughout the toolpath, eliminating the acceleration and deceleration that creates dwell marks at direction changes.

-

Maintain Consistent Coolant Flow - Ensure uninterrupted coolant delivery to the cutting zone and verify that chips evacuate completely between passes to prevent recutting and surface scratching.

These five steps work together as a system. Skipping any single step will compromise your results, regardless of how well you execute the others.

Advanced Finishing Strategies and Surface Integrity

Let's explore the critical relationship between machining strategy and final mold performance. When you machine H13, you're not just creating a specific geometry – you're also establishing the surface integrity that determines how long the mold will survive in production. Poor finishing practices introduce subsurface damage that drastically reduces mold life, even when surface measurements suggest acceptable roughness values.

Understanding White Layer Formation: During aggressive machining, the extreme heat and pressure at the cutting edge can create what metallurgists call "white layer" or "white etching layer." This is a re-hardened zone in the immediate subsurface where the material has been heated above its austenitizing temperature and then rapidly cooled (quenched) by the surrounding material and coolant. White layer is extremely brittle and contains high residual tensile stresses. Under the thermal cycling of production, this layer quickly develops micro-cracks that propagate into the base material, causing premature heat checking and mold failure.

To avoid white layer formation, you must keep peak temperatures below H13's tempering temperature (approximately 1000-1050°F depending on the specific tempering cycle used). This requires managing your chip load and cutting speed carefully. Additionally, never allow your finishing tool to dwell in one position, as this generates heat without removing material. Use continuous motion toolpaths like trochoidal finishing or spiral patterns that maintain constant tool engagement.

Toolpath Strategy Deep Dive: Your CAM programming decisions have enormous impact on surface quality. Traditional back-and-forth parallel toolpaths create direction changes where the machine must decelerate, change direction, and accelerate. During these transitions, feed rate varies, which changes chip load and creates subtle cusps or dwell marks on the surface. Instead, use one of these advanced strategies:

Spiral Toolpaths: Program the tool to move in continuous spiral patterns that eliminate direction reversals entirely. Start from the outside and spiral inward, or vice versa depending on your geometry. This approach maintains constant feed rate and chip load throughout the entire pass.

Trochoidal Finishing: This strategy uses small circular motions combined with forward feed to create a smooth, flowing toolpath. The circular motion helps maintain tool engagement while the forward component advances the cutting process. Trochoidal paths dramatically reduce cutting forces compared to conventional linear paths.

Constant Scallop Height: When finishing complex 3D surfaces, ensure your CAM system calculates step-over distances that maintain uniform scallop height across the entire surface. Variable scallop heights create inconsistent cutting conditions that show up as visible bands or stripes in the finished surface.

Residual Stress Management: Every machining operation introduces residual stresses into the workpiece surface. Tensile stresses are particularly problematic because they add to the operational stresses the mold experiences during casting cycles. The combination can exceed the material's fatigue strength, initiating cracks. Optimized finishing parameters that use sharp tools, light depths of cut, and appropriate feeds generate compressive residual stresses instead. Compressive stresses are beneficial because they must be overcome before tensile stresses can develop, effectively increasing the material's resistance to crack initiation.

To verify your finishing process isn't causing problems, periodically inspect finished surfaces using metallographic cross-sections. A properly finished H13 surface should show no white layer, minimal subsurface deformation, and grain structure that matches the bulk material right up to the surface. If you observe problems, reduce your speeds and feeds further, verify tool sharpness, and confirm adequate coolant delivery.

When your finishing process meets these standards, the molds you produce will deliver significantly longer service life in demanding applications. This quality level separates basic CNC machining service providers from those who truly understand material science and its practical implications for component performance.

Conclusion

Mastering H13 die mold machining transforms a challenging material into a profitable opportunity. Throughout this guide, we've explored why H13 presents unique obstacles and, more importantly, exactly how to overcome them systematically. The key takeaways are clear: success depends on selecting proper PVD-coated tooling, implementing carefully optimized parameters that manage heat generation, and understanding how your machining decisions directly impact the final mold's service life in production.

Remember that the parameters and strategies presented here serve as your starting foundation, not rigid rules. Every machining setup has unique characteristics – your specific machine tool's rigidity, spindle performance, coolholder quality, and even your shop's ambient temperature all influence optimal parameters. Therefore, approach H13 machining as an ongoing learning process where you continuously refine your techniques based on measured results.

The investment you make in proper tooling and process development pays substantial dividends. By reducing tool consumption, minimizing cycle times, and producing molds with superior surface integrity, you'll significantly improve your project profitability. Additionally, your customers will notice the difference when their molds deliver longer production runs between maintenance intervals.

Start by implementing the parameter library provided in this guide for your next H13 project. Monitor your results carefully, tracking tool life, surface finish measurements, and any issues that arise. As you gain experience with these techniques, you'll develop the confidence to tackle even the most demanding mold projects. Whether you're producing components for die casting, automotive tooling, or other industrial machinery applications, these proven strategies will help you deliver consistent, high-quality results that build your reputation and grow your business.

Recommended Resources

[H13 CNC feeds and speeds][^1]

[Best cutter for H13 die mold][^2]

[H13 die mold CNC milling parameters][^3]

[H13 tool wear reduction][^4]

---

[^1]: Understanding the optimal feeds and speeds for H13 can significantly enhance machining efficiency and tool life.

[^2]: Exploring the best cutter options can help you achieve superior finishes and precision in H13 die mold applications.

[^3]: Understanding optimal CNC milling parameters for H13 die mold can enhance machining efficiency and product quality.

[^4]: Exploring effective strategies for H13 tool wear reduction can significantly extend tool life and reduce costs.