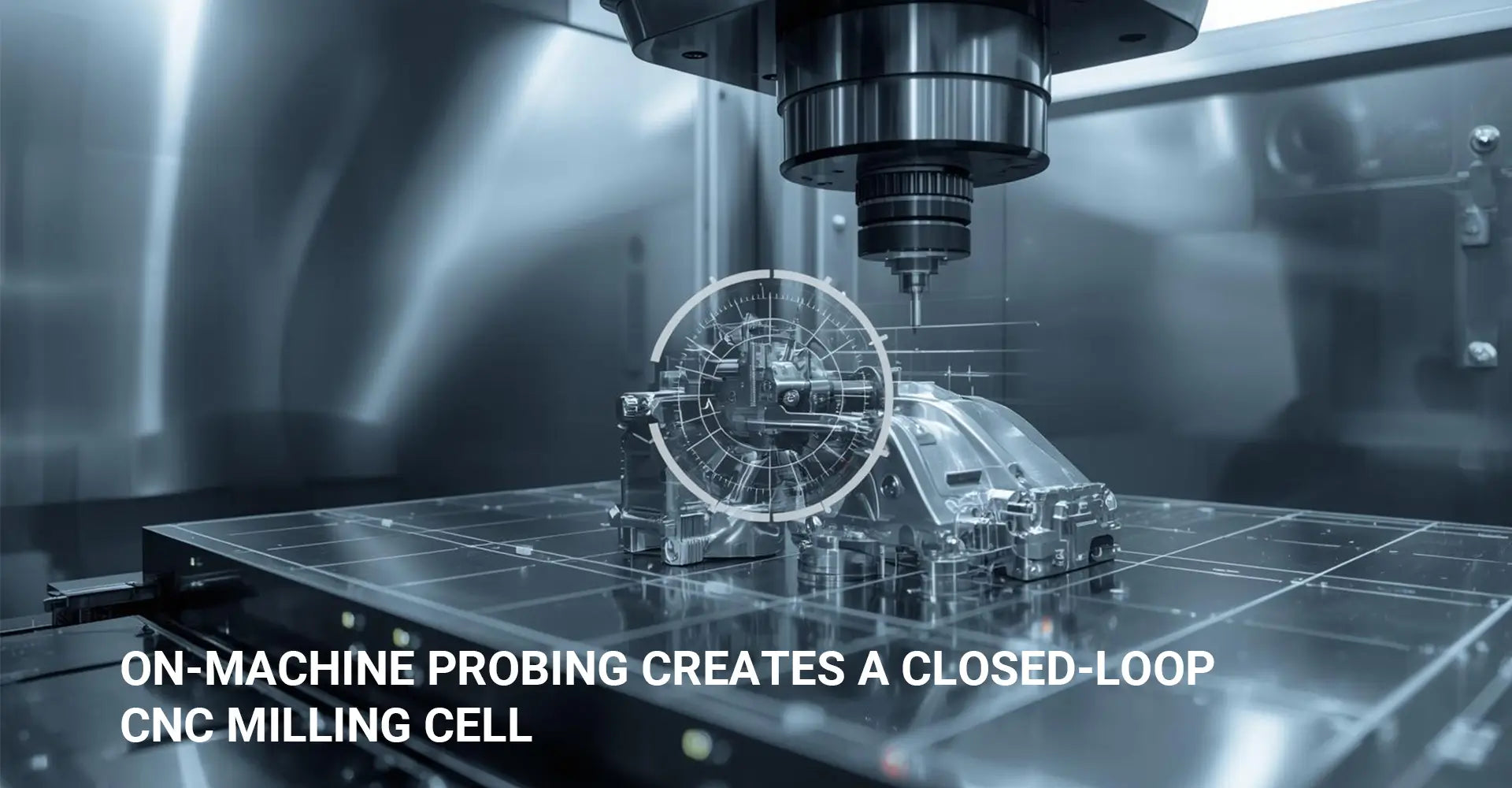

Slash Inspection Time by 70%: How On-Machine Probing Creates a Closed-Loop CNC Milling Cell?

Slash Inspection Time by 70%: How On-Machine Probing Creates a Closed-Loop CNC Milling Cell?

Modern CNC shops face a critical bottleneck that's costing them thousands of dollars daily. While your machines produce precision parts in minutes, those same parts sit in inspection queues for hours. Furthermore, traditional offline inspection creates a disconnect between machining and quality control. However, CNC milling on-machine inspection eliminates this gap entirely. Additionally, it transforms your CNC into a self-correcting system that delivers ±0.01mm accuracy while cutting inspection time by 70%.

Key Benefits at a Glance:

- Time Savings: Reduce first-piece inspection from 4 hours to 75 minutes

- Accuracy: Achieve ±0.01mm precision with closed-loop control

- Cost Reduction: Eliminate CMM queuing and part handling time

- Quality: Enable 100% first-acceptance parts through real-time correction

- Flexibility: Perfect for both high-volume production and job shops

Before diving into the technical details, let's examine why traditional inspection methods create such significant productivity losses. Moreover, we'll explore how integrating measurement directly into your machining process can solve these challenges permanently.

Table of Contents

- The CMM Bottleneck: Why Offline Inspection Is Killing Your Productivity?

- Laser Scanners vs. Touch Probes: Which In-Process Sensor Fits Your Application?

- The Closed-Loop Workflow: How Real-Time Measurement Enables Automatic CNC Adjustments?

- Case Study Results: How One Shop Achieved 100% First-Acceptance on Complex Parts?

The CMM Bottleneck: Why Offline Inspection Is Killing Your Productivity?

Every machine shop knows the frustration of watching finished parts pile up while waiting for CMM availability. In fact, studies show that parts spend more time waiting for inspection than actually being machined. Additionally, this bottleneck becomes more severe as part complexity increases and batch sizes decrease.

Hidden Costs of Offline Inspection:

- Queue Time: Parts wait 2-8 hours for CMM availability

- Handling Time: 15-30 minutes for unloading, transport, and re-fixturing

- Setup Time: 20-45 minutes for CMM programming and alignment

- Scrap Risk: Late detection means entire batches at risk

- Labor Waste: Operators idle while waiting for inspection results

The traditional inspection workflow creates multiple failure points that compound productivity losses. First, parts must be unclamped and transported, introducing handling errors. Next, they require re-fixturing on the CMM, which creates new datum references. Then, CMM programming takes additional time for each unique part geometry. Meanwhile, your expensive CNC machining service equipment sits idle waiting for inspection approval. Most importantly, any dimensional issues discovered hours later mean entire batches could be affected. Therefore, breaking this cycle requires bringing inspection directly to the point of production.

Laser Scanners vs. Touch Probes: Which In-Process Sensor Fits Your Application?

Choosing the right on-machine probing technology depends on your specific application requirements. However, both touch probes and laser scanners offer unique advantages for different measurement tasks. Furthermore, many advanced setups combine both technologies for comprehensive coverage.

Touch Trigger Probes vs. Laser Scanners:

| Feature | Touch Probes | Laser Scanners |

|---|---|---|

| Contact Type | Physical contact | Non-contact laser |

| Best Applications | Holes, bosses, depths | Complex contours, surfaces |

| Accuracy | ±0.001mm | ±0.01mm |

| Speed | Moderate | Very fast (1000s points/sec) |

| Part Damage Risk | Minimal contact force | Zero contact |

Touch probes excel at measuring discrete geometric features with exceptional accuracy. Specifically, they're ideal for checking hole positions, boss heights, and pocket depths. Additionally, their physical contact ensures reliable measurement even on challenging surface finish conditions. Conversely, laser scanner integration enables capture of thousands of data points per second, making them perfect for complex surface verification. Moreover, they can perform 100% inspection of intricate contours that would take hours with traditional methods. However, surface finish and material properties can affect laser measurement reliability. Therefore, understanding your primary measurement requirements helps determine the best sensor choice. Ultimately, combining both technologies provides the most comprehensive on-machine inspection capability.

The Closed-Loop Workflow: How Real-Time Measurement Enables Automatic CNC Adjustments?

Closed-loop machining represents the pinnacle of adaptive manufacturing technology. Instead of passive execution, your CNC becomes an intelligent system that measures, analyzes, and corrects in real-time. Furthermore, this approach eliminates the traditional disconnect between machining and inspection.

The 5-Step Closed-Loop Process:

- Machine: CNC mills the part according to programmed path

- Measure: Integrated probe captures critical dimensions automatically

- Analyze: Control system compares measurements to CAD specifications

- Compensate: Software calculates tool offset corrections automatically

- Machine Again: Final finishing pass with corrected parameters

The closed-loop workflow transforms how industrial machinery handles dimensional accuracy challenges. Initially, the system machines according to nominal programming. Then, in-process measurement immediately captures critical features without removing the part. Next, sophisticated software compares these measurements to design specifications within seconds. If deviations exceed tolerance, real-time quality control automatically calculates compensation values. Subsequently, tool offset update modifications are applied for finishing operations. This adaptive machining process accounts for tool wear, thermal growth, and setup variations in real-time. Consequently, each part receives individualized correction, ensuring consistent quality regardless of changing conditions. Most importantly, this happens automatically without operator intervention, maintaining production flow while guaranteeing specification compliance.

Case Study Results: How One Shop Achieved 100% First-Acceptance on Complex Parts?

A leading aerospace component manufacturer faced recurring quality issues with complex titanium parts. Previously, their rejection rate reached 15% due to late detection of dimensional problems. However, implementing on-machine inspection completely transformed their results.

Measurable Results Achieved:

- Quality: 100% first-acceptance rate on complex aerospace parts

- Time Savings: First-piece inspection reduced from 4 hours to 75 minutes

- Cost Reduction: Eliminated $50,000 annual scrap costs

- Productivity: 35% increase in overall throughput

- Customer Satisfaction: Zero quality complaints since implementation

This aerospace supplier's transformation began with analyzing their biggest quality challenges. Initially, complex titanium brackets required multiple setups and critical tolerances of ±0.005mm. Traditional inspection meant parts sat for hours before discovering any issues. Consequently, rejected parts resulted in expensive titanium waste and missed delivery schedules. After installing laser scanning and touch probe systems, they achieved immediate feedback on every critical dimension. The closed-loop system automatically compensated for tool deflection and thermal effects during machining. Additionally, operators received real-time quality data instead of waiting for CMM reports. Most importantly, post-process elimination prevented defects rather than just detecting them. Today, they consistently deliver custom CNC milling services that meet aerospace specifications on the first attempt, while achieving reduce inspection time CNC operations by over 70%.

Conclusion

On-machine inspection with closed-loop control represents a fundamental shift from reactive to proactive quality management.

Rather than treating inspection as a separate process, integrating measurement directly into machining creates a self-correcting system. Moreover, the benefits extend beyond time savings to include improved accuracy, reduced scrap, and higher customer satisfaction. Additionally, this technology proves valuable for both high-volume production and job shop environments working with CNC metals plastics across various industries. Furthermore, the ROI becomes apparent within months through reduced inspection time and eliminated scrap costs. Therefore, manufacturers who adopt on-machine inspection gain a significant competitive advantage through faster delivery and consistent quality. Ultimately, closed-loop CNC milling cells represent the next step in precision manufacturing capabilities.

[External Links Recommendation]

[CNC milling on-machine inspection][^1]

[on-machine probing][^2]

[closed-loop machining][^3]

[reduce inspection time CNC][^4]

---

[^1]: Understanding CNC milling on-machine inspection can enhance your machining accuracy and efficiency.

[^2]: Exploring on-machine probing will help you improve your quality control processes in CNC machining.

[^3]: Explore this link to understand how closed-loop machining enhances precision and efficiency in manufacturing.

[^4]: Discover strategies and technologies that help minimize inspection time, improving overall productivity.

[^5]: Explore this link to understand the innovative techniques and benefits of adaptive machining in manufacturing.