Will 3D Printing Transform the Future of Manufacturing Forever?

Will 3D Printing Transform the Future of Manufacturing Forever?

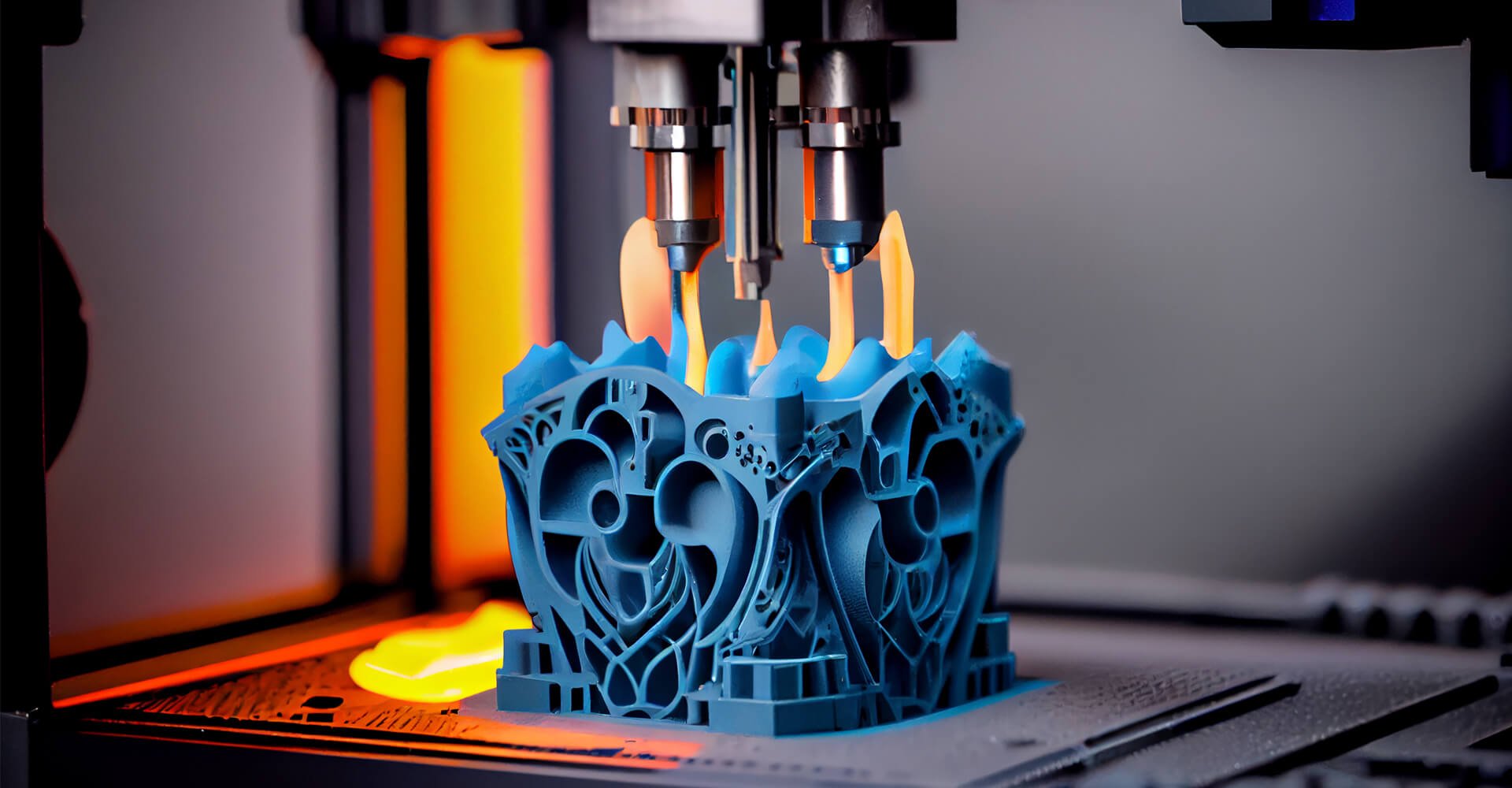

Manufacturing is on the brink of a revolutionary transformation, with 3D printing emerging as a game-changing technology that promises to redefine how we create, design, and produce objects across multiple industries.

The global 3D printing market is experiencing unprecedented growth, projected to expand from $20.68 billion in 2023 to an impressive $150.20 billion by 2032, representing a remarkable 23.6% compound annual growth rate.

As businesses and innovators continue to explore this groundbreaking technology, understanding its potential becomes crucial for forward-thinking professionals and entrepreneurs.

Table of Contents

- Introduction to 3D Printing

- Market Trends and Growth

- Applications Across Industries

- Technological Innovations

- Challenges and Limitations

- Future Outlook

What Exactly is 3D Printing and How Did Technology Evolve?

3D printing, also known as additive manufacturing, represents a cutting-edge method of creating three-dimensional objects by layering materials with extraordinary precision. The technology's journey began in the 1980s, transforming from a niche prototyping technique to a sophisticated manufacturing solution.

Early 3D printing technologies were limited in materials and complexity. Today's advanced printers can create intricate components for various industries, from automotive parts to sophisticated electronics manufacturing components.

The process works by converting digital 3D models into physical objects through precise layer-by-layer construction, enabling unprecedented design flexibility and manufacturing capabilities.

Are Current Market Trends Signaling a 3D Printing Revolution?

The global 3D printing market demonstrates extraordinary potential, with compelling statistics highlighting its transformative impact:

Key Market Insights:

- 70% of businesses increased part production in 2023

- Medical sector shows highest potential for impact (77% of respondents)

- Projected Compound Annual Growth Rate (CAGR): 23.6%

3D Printing Market Growth and Industry Adoption Rates Preview Code

These statistics clearly indicate that 3D printing is not merely a trend but a revolutionary technology poised to reshape manufacturing paradigms.

What Industries Are Embracing 3D Printing Technologies?

Multiple industries are discovering unique applications for 3D printing technologies, leveraging its flexibility and precision:

Primary Application Areas:

- Medical: Customized prosthetics and patient-specific implants

- Automotive: Rapid prototyping and specialized component manufacturing

- Electronics: Precision surface finishing and complex circuit board production

- Aerospace: Lightweight, intricate component design

- Consumer Products: Personalized and on-demand manufacturing

By enabling rapid prototyping, minimizing material waste, and offering unparalleled design freedom, 3D printing is becoming an essential innovation tool across sectors.

What Technological Innovations Are Driving 3D Printing Forward?

Continuous technological advancements are expanding 3D printing's capabilities and potential applications. Different printing methods offer unique advantages for various use cases.

Key 3D Printing Technologies:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Binder Jetting

Each technology brings distinctive strengths, empowering manufacturers to select the most appropriate method for their specific requirements.

What Challenges Remain in 3D Printing Technology?

Despite its tremendous potential, 3D printing confronts several challenges that require strategic addressing:

Key Challenges:

- Material compatibility limitations

- High initial equipment investments

- Complex quality control processes

- Regulatory compliance complexities

- Environmental sustainability concerns

Understanding and systematically overcoming these obstacles will be critical for the technology's continued growth and mainstream adoption.

What Does the Future Hold for 3D Printing?

The future of 3D printing appears incredibly promising, with experts predicting continuous technological innovations and expanded capabilities:

Future Predictions:

- Reduced production costs

- More sustainable manufacturing processes

- Enhanced precision and speed

- Expanded material compatibility

- Greater customization opportunities

Conclusion

3D printing stands at the forefront of a technological revolution, offering unprecedented opportunities for innovation, efficiency, and customization across multiple industries. Businesses and professionals who embrace and explore its potential will be strategically positioned to lead in the evolving manufacturing landscape.

Recommended External Resources

-

Posted in

3D Printing