How Does 5-Axis Machining Create Better Aluminum Heat Sinks?

How Does 5-Axis Machining Create Better Aluminum Heat Sinks?

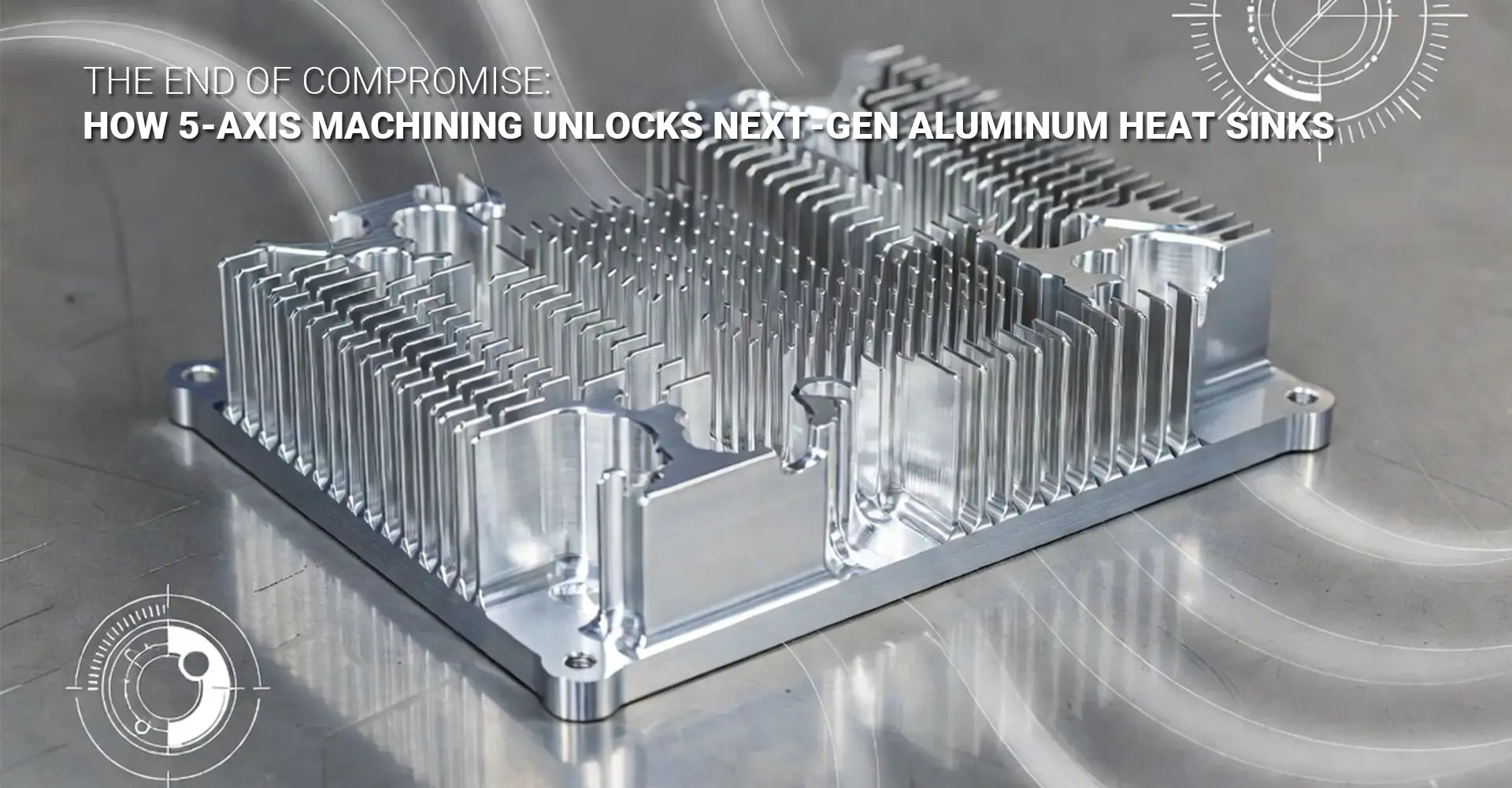

When your thermal management solution hits a wall, the problem often isn't your cooling strategy—it's the manufacturing method holding you back. Traditional heat sinks force engineers into uncomfortable compromises between what's thermally ideal and what's actually buildable. However, advanced machining techniques are changing this equation entirely.

Quick Answer: What You Need to Know Right Now

Key Takeaways at a Glance:

| Factor | Benefit |

|---|---|

| Thermal Conductivity | 6061-T6 aluminum delivers 167 W/mK vs. 96 W/mK in die-cast options |

| Design Freedom | Create curved fins, asymmetric patterns, and conformal cooling impossible with extrusion |

| Performance Gain | Direct integration eliminates thermal interface layers for better heat transfer |

| Best Applications | High-power electronics, space-constrained designs, and custom prototypes |

| Cost Sweet Spot | Higher per-unit cost justified by superior performance in low-to-medium volumes (1-500 units) |

| Material Waste | Lower material utilization offset by zero tooling costs and rapid turnaround |

This information solves the core question most thermal engineers face: whether to stick with proven extrusion methods or invest in advanced manufacturing for better cooling performance.

Most engineers discover that the answer depends entirely on their specific thermal budget and production volume. Moreover, understanding when traditional methods fail helps clarify when advanced techniques become necessary rather than optional.

Table of Contents

- What Limits Do Traditional Heat Sink Methods Face?

- How Does 5-Axis Machining Break Design Barriers?

- Which Heat Sink Features Need 5-Axis Technology?

- When Should You Choose 5-Axis Over Extrusion or Casting?

- Conclusion

What Limits Do Traditional Heat Sink Methods Face?

Every thermal engineer eventually encounters the same frustrating wall. Your calculations show that you need more surface area in a specific zone, or perhaps fins that curve to match your airflow pattern. Unfortunately, your manufacturing partner responds with a polite "that's not possible with our process."

The Thermal Design Trap: Why Standard Methods Hit Performance Ceilings

Critical Limitations of Conventional Manufacturing:

- Extrusion constraint: Forces perfectly straight fins in one direction only—no curves allowed

- Die casting weakness: Offers 3D shapes but delivers poor thermal conductivity at 96 W/mK

- Thin wall challenges: Both methods struggle with walls thinner than 2mm

- Geometry restrictions: Complex undercuts and variable fin spacing remain impossible

Therefore, most heat sinks represent compromises between what thermal analysis demands and what manufacturing allows. This gap becomes particularly painful in high-power applications where every degree matters.

The fundamental issue stems from how these processes work. Extrusion pushes heated aluminum through a shaped die, which means the entire cross-section must remain constant along the length. Consequently, any feature that changes direction or varies in size becomes physically impossible to create.

Die casting offers more geometric freedom since molten aluminum fills a mold cavity. Nevertheless, the casting alloys (typically A380) contain silicon and other elements that improve flowability but drastically reduce thermal conductivity. Additionally, micro-porosity in cast parts creates invisible barriers to heat flow that measurements confirm but eyes cannot see.

When automotive applications demand lightweight cooling solutions, these limitations become even more apparent. The same constraints affect industrial machinery where space comes at a premium and every millimeter counts toward fitting components into tight enclosures.

How Does 5-Axis Machining Break Design Barriers?

The breakthrough comes from simultaneously controlling tool movement in five directions. Instead of being limited to straight cuts or simple cavities, the cutting tool can approach the workpiece from virtually any angle while the part rotates and tilts beneath it.

What 5-Axis Technology Delivers to Thermal Engineers

Transformative Capabilities for Heat Sink Production:

- Material superiority: 6061-T6 billet provides 74% better thermal conductivity than die-cast aluminum (167 W/mK vs. 96 W/mK)

- Complete geometrical freedom: Cutting tool approaches from any angle to create undercuts, curves, and complex transitions

- Surface quality advantage: Achieves base flatness within 0.025mm and surface finishes below 0.8µm Ra

- Single-setup integration: Combines mounting holes, fins, interface surfaces, and structural features without repositioning

This capability matters because thermal resistance depends heavily on material quality and interface contact. A machined base surface makes full contact with your heat source, whereas a rougher cast surface creates air gaps that act as insulators.

The process begins with solid billet material—essentially a block of high-purity aluminum with consistent grain structure throughout. Since CNC machining services remove material rather than forming it, there's no opportunity for porosity or inclusions to develop. Each chip that comes off reveals perfectly dense metal underneath.

Furthermore, the simultaneous 5-axis movement means the cutting tool maintains optimal orientation relative to the surface being created. This results in superior surface finish without secondary operations. The fins emerge from the base with full material continuity—no brazed joints or thermal barriers exist between base and fins.

Modern CAM software calculates efficient tool paths that remove material rapidly using dynamic milling strategies. Consequently, cycle times for complex aluminum heat sink manufacturing have decreased dramatically compared to early 5-axis applications. What once took 20 hours might now complete in 4-6 hours depending on size and complexity.

Which Heat Sink Features Need 5-Axis Technology?

Certain cooling designs simply cannot exist without multi-axis machining capabilities. These aren't minor improvements over conventional heat sinks—they represent fundamentally different approaches to thermal management that unlock performance levels previously unattainable.

Advanced Heat Sink Designs That Require 5-Axis Capabilities

Impossible-Without-5-Axis Design Elements:

- Conformal cooling fins: Curved fin surfaces that follow airflow patterns from fans or natural convection currents

- Variable fin geometry: Fin density increases from 2mm pitch to 1mm pitch across the base to match heat flux distribution

- Asymmetric layouts: Fins reach 40mm height in hotspot zones while remaining 20mm elsewhere

- Integrated flow turbulators: Microscopic vortex generators machined directly onto fin sidewalls to disrupt boundary layers

- Non-planar mounting: Cooling fins machined directly onto curved housings or cylindrical surfaces

- Precision thin walls: Fin thickness down to 0.5mm maintained across entire height for maximum surface area density

These features address specific thermal challenges that conventional heat sinks cannot solve. For instance, when a power module generates most heat in one corner, variable fin density directs cooling capacity exactly where needed rather than wasting it on cooler areas.

Consider a real-world application: high-power IGBT modules in industrial motor drives. These semiconductor devices generate intense heat in a small footprint, often within curved enclosures. A standard extruded heat sink with uniform straight fins would leave significant cooling potential unused while still failing to prevent hotspots.

The 5 axis heat sink machining approach creates a solution tailored to the actual thermal load distribution. Taller, denser fins sit directly over the IGBT dies where heat flux exceeds 50 W/cm². Meanwhile, the fin pattern curves to follow the enclosure shape, eliminating wasted space. Additionally, thin wall aluminum machining techniques allow fin thickness to drop to 0.7mm, packing more surface area into the same footprint.

Testing proves the impact. In a recent comparison, a custom machined heat sink reduced junction temperature by 18°C compared to the best available extruded alternative in the same mounting envelope. This improvement came from three factors working together: better thermal conductivity in the base material, conformal cooling fins aligned with airflow, and a precision-machined interface surface that eliminated air gaps.

The thermal solution for high power electronics often demands these exact capabilities. Power densities continue increasing while available space shrinks, creating what engineers call the "thermal crisis" in electronics packaging. Standard solutions simply cannot keep pace with the heat generation rates in modern devices.

High performance heat sink design now routinely incorporates features that were experimental just five years ago. Airfoil-shaped fins reduce pressure drop by 30% compared to rectangular fins, allowing the same fan to move more air through the heat sink. Offset fin patterns create turbulent mixing that breaks up the thermal boundary layer where heat transfer normally stalls.

When Should You Choose 5-Axis Over Extrusion or Casting?

The question isn't whether advanced machining performs better—it clearly does. Instead, engineers must determine when that performance advantage justifies the higher per-unit cost. This decision framework helps clarify when to specify machined heat sinks versus sticking with conventional methods.

Making the Smart Choice for Your Application

5-Axis Machining Makes Economic and Technical Sense When:

- Space constraints demand it: Non-rectangular footprints, curved surfaces, or integration into structural components

- Thermal budget is exhausted: Standard heat sinks fail to meet temperature targets even with maximum airflow

- Production volumes support it: Quantities from 1 prototype to 500 production units where tooling costs cannot be justified

- Performance drives value: Applications where reliability depends on staying below critical temperatures

- Localized cooling matters: Heat sources concentrate in specific zones requiring targeted fin geometry

- Development speed counts: Custom heat sink prototyping without 8-12 week tooling lead times

- Premium applications justify cost: Aerospace, defense, medical devices, or high-end industrial equipment

Conversely, stick with extrusion when you need thousands of identical units with simple straight fins. The economies of scale make extrusion unbeatable for high-volume production of standardized designs.

Let's examine the numbers concretely. An extruded heat sink might cost $3-8 per unit at volumes above 1,000 pieces, but requires $5,000-15,000 in extrusion die tooling. That same design machined from billet might cost $45-120 per unit with zero tooling investment. The break-even point typically falls around 300-500 units depending on complexity.

However, this simple cost comparison misses a crucial point. If the extruded version cannot meet your thermal requirements, its lower price becomes irrelevant. You're comparing the cost of a solution against the cost of a non-solution.

The extrusion vs machined heat sink decision often hinges on thermal performance requirements rather than pure economics. Engineers working with CNC metals and plastics understand that material selection and manufacturing method fundamentally determine what thermal performance is achievable.

Consider development timelines as well. Extrusion requires designing the die, manufacturing it, running initial samples, and iterating if the design needs changes. This process typically consumes 8-16 weeks. Meanwhile, machining a heat sink from a CAD model can happen in 3-5 days for simple designs, or 1-2 weeks for highly complex geometries.

This speed advantage makes machining the obvious choice for prototyping regardless of planned production volume. Test your thermal design with a machined prototype, validate performance in actual operating conditions, then decide whether to tool up for extrusion if volumes justify it.

The material quality factor deserves emphasis. When you machine from 6061-T6 billet, you get guaranteed thermal conductivity of 167 W/mK with zero porosity. Die-cast heat sinks using A380 alloy provide roughly 96 W/mK, and that number assumes zero porosity—actual parts often perform worse due to micro-voids. This 74% difference in thermal conductivity translates directly to temperature reduction.

Application criticality matters too. If your heat sink cools a $50 component in a consumer product, maybe "good enough" thermal performance justifies choosing extrusion. But if that heat sink protects a $5,000 power module in a medical device where failure means patient risk, the decision calculus changes completely. The machined heat sink's superior performance becomes cheap insurance.

Conclusion

The answer comes down to three simple questions. First, have you exhausted conventional cooling options? Second, does your thermal budget demand the absolute best heat transfer possible? Third, are your production volumes compatible with higher per-unit costs?

If you answered "yes" to these questions, then advanced machining techniques offer capabilities that simply don't exist in extrusion or casting. You gain the freedom to design heat sinks around thermal requirements rather than manufacturing limitations.

The technology has matured beyond experimental status. Modern 5-axis machining centers, coupled with sophisticated CAM software, produce complex heat sinks reliably and repeatably. Lead times have shortened, costs have decreased, and the performance advantages remain undeniable.

Thermal challenges continue intensifying across industries. Power electronics pack more watts into smaller spaces. Electric vehicle inverters demand extreme cooling in hostile environments. Data center processors push thermal densities beyond what air cooling was thought capable of handling.

These applications need more than incremental improvements in heat sink design. They demand fundamental advances in geometry, material quality, and manufacturing precision. That's exactly what 5-axis machining delivers—the ability to create the heat sink your thermal analysis says you need, rather than settling for the heat sink that's easy to manufacture.

Start by evaluating your current thermal design. Are you hitting temperature targets with margin, or barely squeaking by? Do you find yourself wanting features that your supplier says aren't possible? Have you added fans or increased airflow to compensate for heat sink limitations?

These symptoms suggest you've outgrown conventional manufacturing methods. The next step is exploring what becomes possible when geometry constraints disappear and material quality maximizes thermal performance.

Recommended Resources

[aluminum heat sink manufacturing][^1]

[High performance heat sink design][^2]

[Extrusion vs machined heat sink][^3]

[Conformal cooling fins][^4]

[Thermal solution for high power electronics][^5]

[Precision machined heat sinks][^6]

---

[^1]: Explore this link to discover essential techniques and innovations in aluminum heat sink manufacturing that can enhance your projects.

[^2]: This resource will provide insights into optimizing heat sink design for maximum efficiency and performance.

[^3]: Understanding the differences can help you choose the best heat sink for your application, optimizing performance and cost.

[^4]: Exploring this topic reveals innovative cooling solutions that enhance efficiency in various engineering applications.

[^5]: Explore this link to discover innovative thermal management techniques essential for high-power electronics.

[^6]: Learn about the advantages of precision machined heat sinks for efficient heat dissipation in electronics.