What Are CNC Machining Shop Rates in 2025 and How Much Should You Really Pay?

What Are CNC Machining Shop Rates in 2025 and How Much Should You Really Pay?

Finding the right CNC machining shop at a fair price can feel like solving a puzzle without all the pieces. Therefore, many businesses struggle with understanding what drives machining costs and how to avoid overpaying. In fact, Reddit discussions reveal that companies often pay 200-300% more than necessary due to hidden fees and poor negotiation strategies.

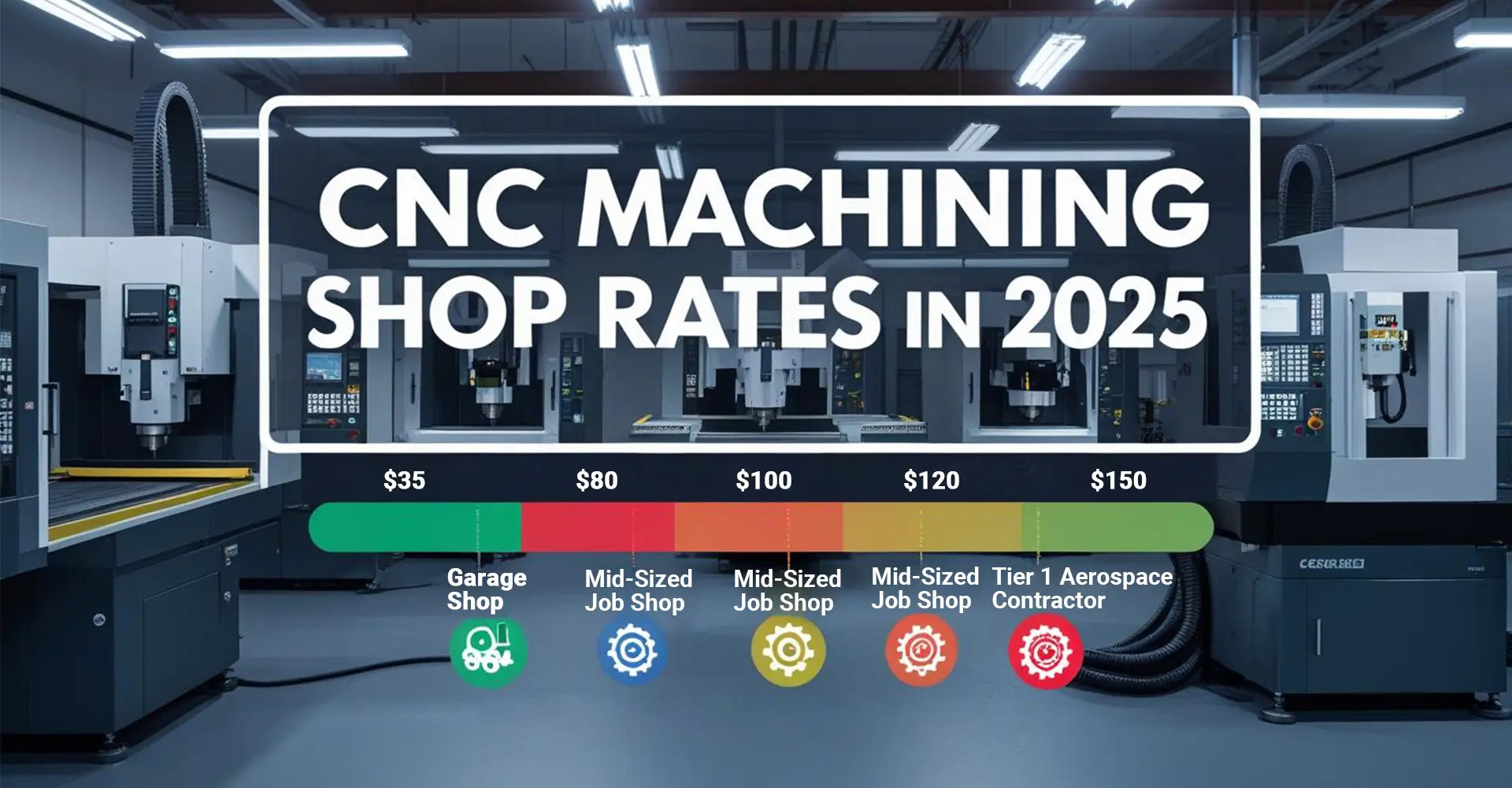

Quick Answer: CNC machining shop rates explained show costs typically range from $35-$150 per hour depending on machine type and complexity. However, the real pricing CNC outsourcing cost includes setup fees ($50-$200), programming charges ($50-$150/hour), and material markups (18-35%). Most importantly, understanding these components helps you negotiate better deals and choose the right shop for your project.

Before diving into specific outsourcing pricing models, let's explore what Reddit users and industry professionals have learned about CNC outsourcing costs. Additionally, we'll break down each cost component so you can make informed decisions for your next project.

Table of Contents

- Why Do CNC Shop Rates Vary So Much?

- What Machine Types Cost the Most to Operate?

- Which Hidden Fees Should You Watch Out For?

- When Does Outsourcing Beat In-House Machining?

Why Do CNC Shop Rates Vary So Much?

CNC shop rates differ dramatically because each facility operates under unique cost structures and business models. Furthermore, location, equipment age, and specialization levels all impact final pricing.

Key Factors: Geographic location creates 22% price differences between Midwest and Coastal shops. Meanwhile, machine shop overhead costs (rent, utilities, insurance) typically account for 15% of hourly rates, while machine depreciation represents 32% of total costs.

According to Reddit users from r/Machining and r/CNC, garage shops charge $35-$45/hour but lack advanced capabilities. In contrast, mid-sized job shops at $65-$85/hour offer better equipment and programming services. Moreover, Tier 1 contractors charging $110-$150/hour provide full metrology and aerospace-grade documentation. Therefore, your choice depends on project requirements rather than just price alone. Additionally, shops specializing in CNC machining services often justify premium rates through superior quality control and faster turnaround times.

What Machine Types Cost the Most to Operate?

Different CNC machines require varying levels of investment, maintenance, and operator skill. Consequently, hourly machining costs reflect these operational differences and complexity levels.

Rate Breakdown: 3-axis mills cost $35-$55/hour for basic operations. Meanwhile, 5-axis machining centers command $75-$130/hour due to programming complexity. Additionally, Swiss turning machines fall in the $60-$95/hour range depending on part intricacy.

Reddit discussions from experienced machinists reveal important cost drivers. First, 5-axis machines require specialized CAM software licenses costing $15,000-$50,000 annually. Second, tooling expenses increase significantly with complex geometries and tight tolerances. Third, operator training for advanced machines takes 2-3 years versus months for basic equipment. Therefore, shops must recover these investments through higher hourly rates while maintaining competitive positioning. Furthermore, specialized services like custom CNC milling and CNC turning require different equipment investments that directly impact pricing structures.

Which Hidden Fees Should You Watch Out For?

Many CNC quotes contain additional charges that aren't immediately obvious. However, understanding these potential hidden CNC fees helps you compare quotes accurately and negotiate better terms.

Top Hidden Costs: CAM programming fees ($50-$150/hour), minimum order charges ($25-$200), and non-standard tooling costs ($120+ per tool). Additionally, material markups range from 18-35% above market prices, while inspection reports can add $50-$150 per part.

Reddit users consistently warn about these surprise charges that inflate final costs. For instance, shops often quote competitive hourly rates but add substantial setup fees for small batches. Moreover, custom tooling requirements can double project costs if not discussed upfront. Similarly, tight tolerances (±0.025mm vs ±0.1mm) may increase machining time by 100% or more. Therefore, always request detailed quotes that itemize all potential charges before committing to any project. Additionally, finishing processes such as surface treatments often carry separate fees that should be clarified during the quoting process. Understanding small batch vs volume pricing helps identify when economies of scale reduce per-unit costs significantly.

When Does Outsourcing Beat In-House Machining?

Deciding between outsourcing and in-house machining requires careful cost benchmarking machining options. Additionally, factors beyond immediate expenses influence this critical business decision.

Break-even Point: In-house machining becomes cost-effective at 1,500+ annual machine hours for basic work. However, 5-axis operations require only 800 hours due to high outsourcing rates. Furthermore, consider equipment costs ($150,000-$500,000), operator salaries ($45,000-$75,000), and ongoing maintenance expenses.

According to r/CNC community discussions, the decision involves multiple variables beyond simple math. First, consider your production volume consistency and seasonal fluctuations. Second, evaluate quality control requirements and inspection capabilities. Third, assess your team's technical expertise and training capacity. Moreover, outsourcing provides flexibility for varying workloads without fixed overhead commitments. However, in-house capabilities offer better scheduling control and intellectual property protection for sensitive projects. Furthermore, companies requiring diverse manufacturing processes might benefit from outsourcing both machining and sheet metal fabrication to specialized vendors. Learning how to negotiate machining quotes effectively becomes crucial for maintaining competitive manufacturing costs.

Conclusion

Understanding CNC machining shop rates requires looking beyond simple hourly prices. Instead, focus on total project costs including all fees and potential overruns. Moreover, choose shops based on capabilities matching your specific requirements rather than lowest quoted rates. Finally, use the insights from Reddit's machining communities to negotiate fairly while building long-term supplier relationships that benefit both parties.

[External Links Recommendation]

[CNC machining shop rates][^1]

[CNC outsourcing cost][^2]

[hourly machining costs][^3]

[hidden CNC fees][^4]

[cost benchmarking machining][^5]

[machine shop overhead costs][^6]

---

[^1]: Understanding CNC machining shop rates can help you budget effectively for your projects and find the best service providers.

[^2]: Exploring CNC outsourcing costs will provide insights into pricing structures and help you make informed decisions for your manufacturing needs.

[^3]: Understanding the factors influencing hourly machining costs can help you budget effectively and choose the right service.

[^4]: Exploring common hidden CNC fees can save you money and ensure transparency in your machining projects.

[^5]: Understanding cost benchmarking in machining can help optimize production costs and improve competitiveness.

[^6]: Exploring overhead costs in machine shops can reveal strategies for cost savings and efficiency improvements.