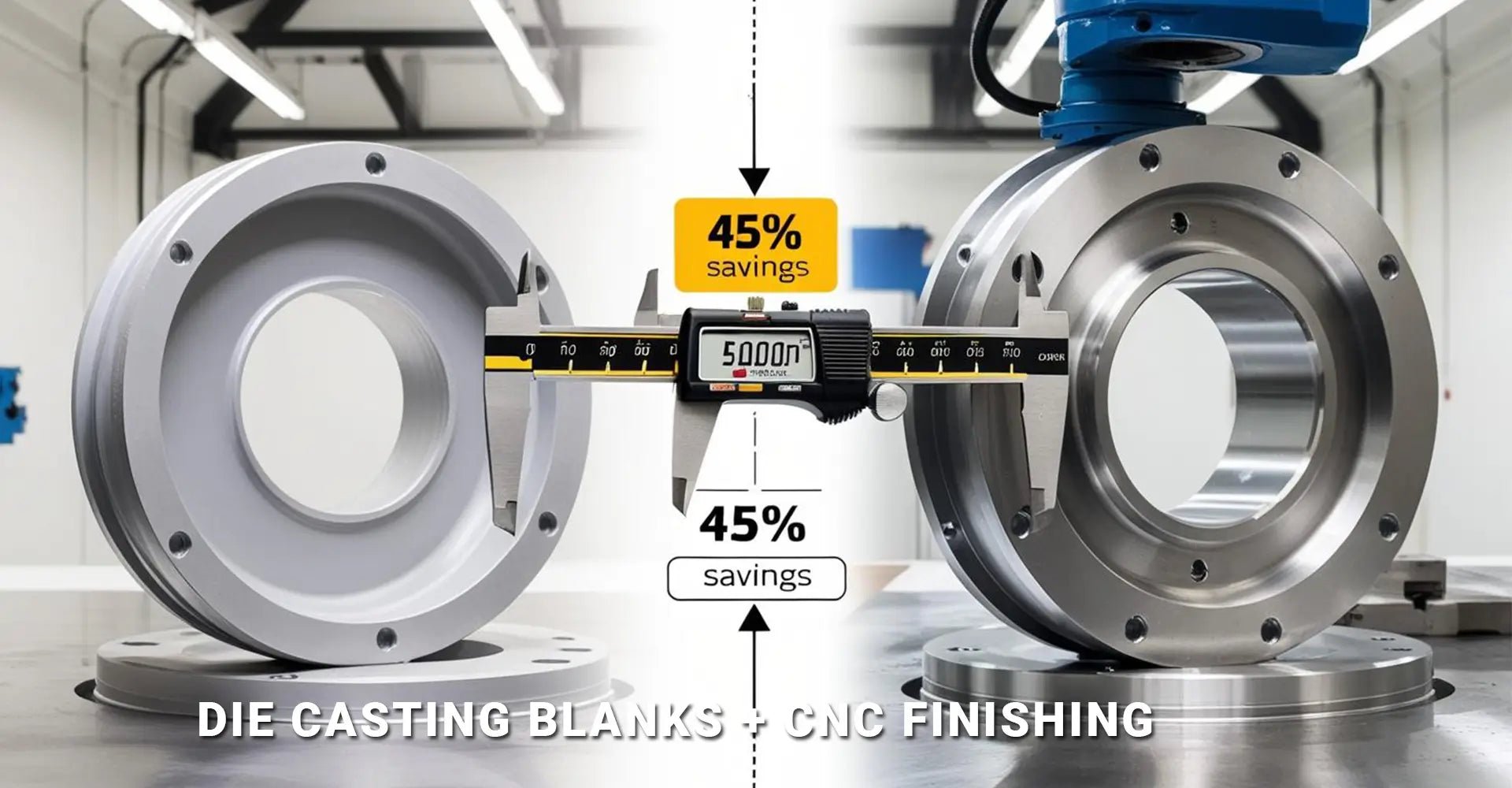

Die Casting Blanks + CNC Finishing: How to Achieve 45% Cost Savings With ±0.05mm Precision?

Die Casting Blanks + CNC Finishing: How to Achieve 45% Cost Savings With ±0.05mm Precision?

Manufacturing complex parts like gearbox housings has traditionally been a costly endeavor, with many companies defaulting to full CNC machining from solid blocks. However, a strategic combination of die casting blanks with selective CNC finishing is changing this paradigm. This hybrid approach not only maintains exceptional precision but dramatically reduces production costs by up to 45% while ensuring ISO 2768-m compliance.

Did you know? Hybrid manufacturing combining die casting with targeted CNC finishing can reduce production costs by 45% while maintaining ±0.05mm precision on critical surfaces. This approach eliminates up to 90% of material waste compared to traditional methods and can cut production time by more than half for complex components like motor and gearbox housings.

Let's explore how this hybrid manufacturing approach works in practice, examine real cost comparisons, and understand why more manufacturers are switching to this method for complex parts production. Whether you're producing appliance components, automotive parts, or industrial equipment, this guide will help you determine if die casting blanks + CNC finishing cost optimization is right for your production needs.

[Table of Contents]

- Why Are Traditional Manufacturing Methods So Expensive for Complex Parts?

- How Does Near-Net-Shape Die Casting Eliminate 90% of Material Waste?

- What Makes Precision CNC Finishing Critical for Functional Surfaces?

- How Much Can You Actually Save? Real-World Cost Analysis

- How Do Manufacturers Maintain ±0.05mm Accuracy Across Production Batches?

- Conclusion

Why Are Traditional Manufacturing Methods So Expensive for Complex Parts?

Complex components like gearbox housings have traditionally been manufactured using full CNC machining from solid aluminum blocks. While this method delivers high precision, it comes with significant drawbacks. The process is labor-intensive, material-wasteful, and extremely time-consuming. A typical gearbox housing might require removing up to 90% of the original material block through machining, resulting in excessive scrap and tool wear.

Key Cost Factors of Traditional Manufacturing:

- CNC machine time costs approximately $120/hr for full block machining

- Material waste reaches 90% when machining from solid blocks

- Tool wear increases dramatically with extended roughing operations

- Energy consumption remains high throughout lengthy machining cycles

When we analyze the cost breakdown, full CNC machining becomes prohibitively expensive for medium to high volume production. For instance, a typical gearbox housing requires 4-6 hours of roughing operations alone before precision finishing can begin. This translates to $480-720 in machine time costs before even reaching the critical precision stages. Additionally, aluminum material costs continue to rise, making the 90% waste rate increasingly problematic for cost-conscious manufacturers. These challenges have pushed the industry to seek cost-effective gearbox housing manufacturing alternatives without compromising on the ±0.05mm precision requirements for critical surfaces.

How Does Near-Net-Shape Die Casting Eliminate 90% of Material Waste?

Near-net-shape die casting for appliance components represents the first critical stage in the hybrid manufacturing approach. This process creates blanks that closely resemble the final part geometry, requiring only minimal material removal during subsequent CNC operations. By casting components with just 0.8mm machining allowances on critical surfaces, manufacturers can drastically reduce or completely eliminate roughing operations.

Benefits of Near-Net-Shape Die Casting:

- Eliminates up to 90% of material waste compared to solid block machining

- Reduces roughing time by 70%, focusing CNC operations only on critical surfaces

- Creates complex internal geometries impossible with traditional machining

- Aluminum ADC12 die casting provides excellent mechanical properties while maintaining cost advantages

The die casting process enables manufacturers to create complex geometries in a single operation, including internal channels, mounting features, and structural ribbing. Advanced vacuum-assisted die casting techniques have significantly improved part quality, reducing porosity to less than 0.1% (per ASTM E505). This improvement addresses historical concerns about die cast part integrity. Modern simulation tools now predict and eliminate potential defects before production begins, ensuring consistent part quality. The small 0.8mm machining allowance provides sufficient material for precision finishing while minimizing CNC time. This approach particularly benefits parts with large surface areas or complex internal features that would otherwise require extensive milling operations.

What Makes Precision CNC Finishing Critical for Functional Surfaces?

While die casting provides an excellent near-net-shape foundation, precision machining of critical sealing surfaces delivers the tight tolerances required for functional components. This targeted approach focuses machining operations exclusively on critical areas like bore holes (requiring H7 tolerance), sealing surfaces (needing Ra 0.8μm finish), and threaded ports. By limiting CNC operations to only these essential features, manufacturing time drops by approximately 67% compared to full CNC approaches.

Critical Surface Requirements Achieved Through Selective CNC:

- Bearing bores machined to H7 tolerance (±0.015mm)

- Sealing surfaces finished to Ra 0.8μm surface roughness

- Threaded ports and mounting holes positioned with ±0.05mm accuracy

- Reference datum features established for precise assembly alignment

The selective CNC finishing process begins with proper fixturing of the die cast blank, establishing precise datum references for all subsequent operations. Multi-axis CNC machines then target only functional surfaces, completing in one-third the time required for full-block machining. Modern CAM software optimizes tool paths specifically for die cast blanks, accounting for the unique material properties of pre-cast components. This specialized approach enables manufacturers to achieve automotive-grade precision (conforming to IATF 16949 standards) while maintaining cost advantages. For example, bearing bores requiring precise H7 tolerances can be machined directly without the hours of preparatory roughing required in traditional methods, significantly reducing production time while maintaining exact specifications.

How Much Can You Actually Save? Real-World Cost Analysis

The financial benefits of hybrid die casting and CNC machining for complex parts become clear when examining actual production scenarios. In a real-world case study involving washing machine motor housings, a 10,000-unit production run demonstrated dramatic cost differences. The hybrid approach delivered finished parts at $18.50/unit compared to $33.80/unit using traditional full CNC methods—a 45% cost reduction with hybrid manufacturing that significantly impacted the product's market competitiveness.

Cost Breakdown Comparison (10,000-unit production):

-

Hybrid Manufacturing: $18.50/unit ($185,000 total)

- Die casting tooling amortization: $3.20/unit

- Raw material: $5.80/unit

- Die casting process: $4.50/unit

- CNC finishing (focused operations): $5.00/unit

-

Traditional Full CNC: $33.80/unit ($338,000 total)

- Raw material block: $11.30/unit

- CNC roughing operations: $14.20/unit

- CNC finishing operations: $8.30/unit

When analyzing the return on investment, the initial die casting tooling costs (typically $25,000-35,000) are quickly offset by the per-unit savings. The break-even point generally occurs between 500-700 units, making this approach ideal for medium to high-volume production runs. Additionally, the hybrid approach reduces lead times by approximately 50%, allowing manufacturers to respond more quickly to market demands. Energy consumption analysis shows further benefits, with hybrid manufacturing consuming approximately 60% less electricity per part due to reduced machining time. These combined advantages make hybrid manufacturing particularly attractive for companies seeking to improve both cost structures and environmental impact while maintaining precise quality standards.

How Do Manufacturers Maintain ±0.05mm Accuracy Across Production Batches?

Maintaining consistent ±0.05mm accuracy across production batches requires robust quality assurance protocols. Successful ISO 2768-m compliant die cast CNC finishing implementations combine sophisticated inspection techniques with statistical process control (SPC) to ensure every part meets exacting standards. This systematic approach begins with die casting process monitoring and extends through final CNC verification.

Key Quality Assurance Elements:

- Coordinate Measuring Machine (CMM) inspection following ISO 10360-2 standards

- Statistical Process Control (SPC) monitoring of critical dimensions

- X-ray inspection of internal features to verify casting integrity

- First Article Inspection (FAI) with comprehensive documentation for each production run

Quality assurance begins at the die casting stage with thermal monitoring of molds and precise control of injection parameters. Each production batch undergoes sampling inspection with advanced CMM systems capable of measuring to ±0.001mm accuracy. These measurements feed into SPC systems that identify any drift in process parameters before tolerances are exceeded. For critical applications, manufacturers implement 100% inspection of key features, ensuring complete compliance with specifications. This comprehensive approach enables motor housing production with ±0.05mm accuracy across tens of thousands of units while maintaining ISO 2768-m compliance. Many leading manufacturers now provide digital quality certificates with each batch, documenting actual measured values for customer verification and traceability.

Conclusion

The combination of die casting blanks with selective CNC finishing represents a significant advancement in manufacturing economics without compromising precision. This hybrid approach delivers substantial benefits: 45% cost reduction, 90% less material waste, and 50% faster production times, all while maintaining ±0.05mm accuracy on critical surfaces. For manufacturers of complex components like gearbox housings, motor casings, and precision industrial parts, this methodology offers a compelling alternative to traditional manufacturing approaches.

Companies adopting this hybrid manufacturing strategy gain competitive advantages through lower production costs, reduced lead times, and improved sustainability metrics. As material costs continue to rise and market pressures demand greater efficiency, the die casting + CNC finishing approach provides a proven solution for modern manufacturing challenges.

[External Links Recommendation]

[Precision machining of critical sealing surfaces][^1]

[45% cost reduction with hybrid manufacturing][^2]

[ISO 2768-m compliant die cast CNC finishing][^3]

[Cost-effective gearbox housing manufacturing][^4]

---

[^1]: Discover the importance of precision machining in achieving high-quality sealing surfaces, crucial for product reliability.

[^2]: Learn how hybrid manufacturing techniques can lead to significant cost savings and improved production efficiency.

[^3]: Explore this link to understand the standards and benefits of ISO 2768-m compliance in CNC finishing processes.

[^4]: Discover innovative strategies for reducing costs in gearbox housing production without compromising quality.

-

Posted in

CNC machining