How Does Die Casting CNC Finishing Cut Automotive Production Time by 40%?

How Does Die Casting CNC Finishing Cut Automotive Production Time by 40%?

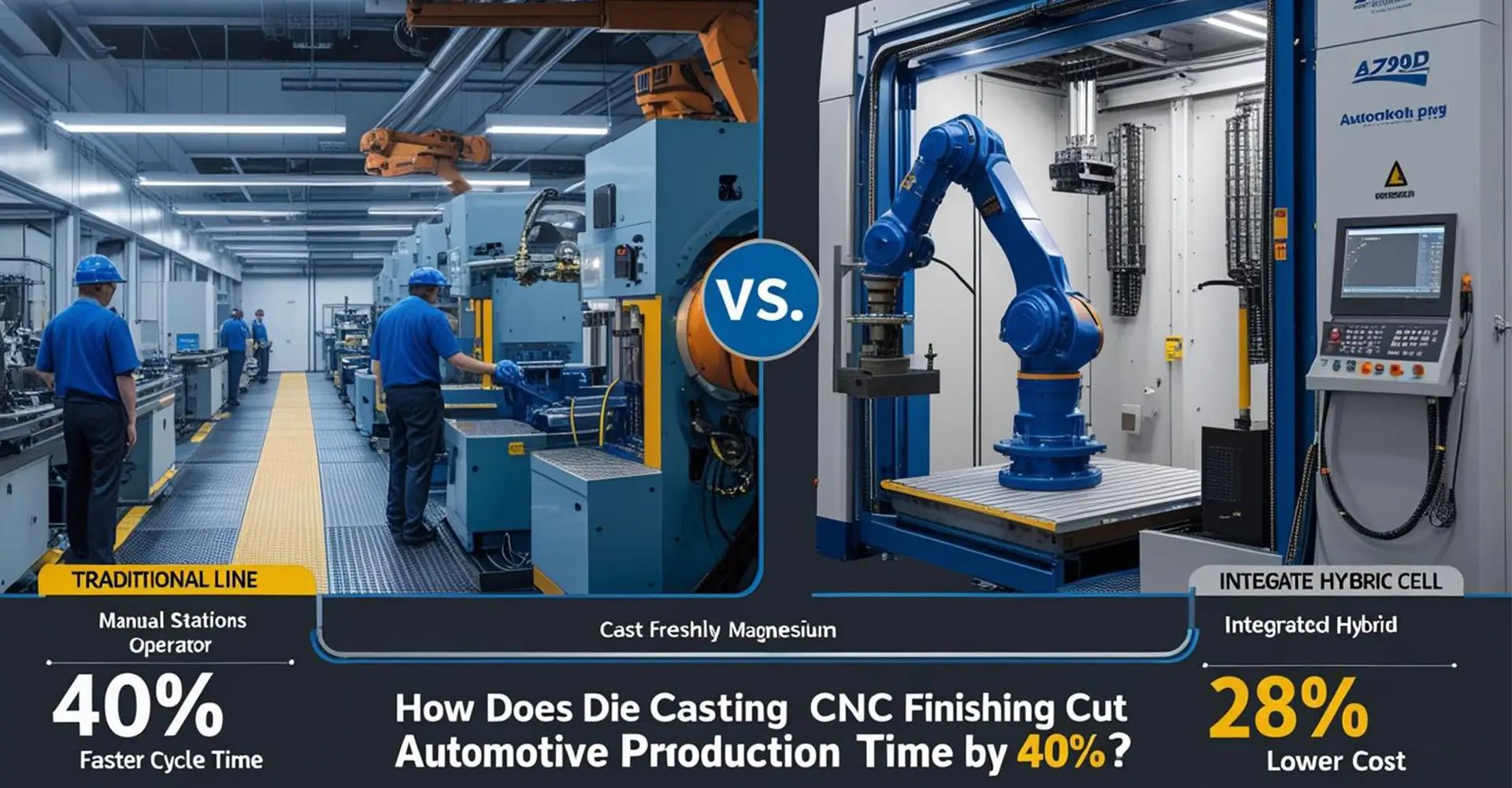

Your automotive heat sink production just became 40% faster and $11.30 cheaper per part. Moreover, traditional die casting methods require multiple setups, handling steps, and secondary operations that waste valuable time. However, hybrid die casting CNC finishing automotive combines casting and machining in one seamless workflow. As a result, manufacturers are seeing dramatic improvements in both quality and cost-effectiveness.

Key Benefits at a Glance:

- ✅ 40% faster cycle time (22 min → 13 min)

- ✅ 28% cost reduction ($39.80 → $28.50 per part)

- ✅ ±0.05mm precision on thin heat sink fins

- ✅ Single setup machining eliminates handling errors

- ✅ AZ91D magnesium provides 33% weight savings

While these results sound impressive, many manufacturers wonder how this hybrid approach actually works in practice. Furthermore, questions about magnesium machining safety and fixture design often create hesitation. Let's explore exactly how die casting solves these automotive production challenges.

[Table of Contents]

- Why Do Traditional Die Casting Methods Create Production Bottlenecks?

- What Makes AZ91D Magnesium Perfect for Automotive Heat Sinks?

- How Does 5-Axis CNC Finishing Work in Die Casting Lines?

- Can You Really Achieve ±0.05mm Precision on Cast Parts?

- Conclusion

Why Do Traditional Die Casting Methods Create Production Bottlenecks?

Traditional automotive die casting follows a lengthy multi-step process that creates unnecessary delays. First, parts get cast with rough surfaces and excess material. Then, they travel to separate trimming stations for flash removal. Next, operators manually transport parts to machining areas. Finally, multiple setups are required to achieve final dimensions.

Traditional Process Timeline:

- Casting: 8 minutes

- Trimming & Transport: 4 minutes

- Fixturing: 3 minutes

- Machining: 7 minutes

- Total: 22 minutes per part

Each handling step introduces potential quality issues and increases labor costs. Additionally, transport between stations creates opportunities for part damage. Meanwhile, multiple fixtures require precise setup and calibration. Consequently, manufacturers experience higher scrap rates and longer lead times. This traditional approach also demands more floor space and specialized operators for each station. Therefore, many automotive manufacturers are seeking alternatives that streamline these bottlenecks.

What Makes AZ91D Magnesium Perfect for Automotive Heat Sinks?

AZ91D magnesium alloy offers unique advantages for automotive heat sink applications. Specifically, this material provides excellent thermal conductivity while maintaining lightweight properties. Moreover, AZ91D machines 50% faster than aluminum alloys. However, proper safety protocols are essential for magnesium die casting CNC operations.

AZ91D Performance Comparison:

- Weight: 33% lighter than aluminum

- Machining Speed: 350 m/min vs. 200 m/min (aluminum)

- Thermal Conductivity: 96 W/m·K

- Castability: Excellent die filling characteristics

The key to safe magnesium machining lies in proper coolant selection and chip management. Therefore, water-free mineral oil coolants prevent ignition risks. Additionally, vacuum chip evacuation systems remove hot material immediately. Sharp cutting tools also prevent heat buildup that could cause ignition. Furthermore, nitrogen purge systems create inert atmospheres around cutting zones. When implemented correctly, AZ91D hybrid manufacturing delivers superior results compared to traditional aluminum casting approaches.

How Does 5-Axis CNC Finishing Work in Die Casting Lines?

Five-axis CNC machining transforms die casting finishing by enabling single-setup operations. Instead of multiple fixtures, parts stay clamped once while all surfaces get machined. Furthermore, robotic transfer systems move parts directly from casting stations to CNC machines. This integration eliminates handling time and reduces quality variations.

Hybrid Line Workflow:

- Cast part with 0.3mm machining allowance

- Robot transfer within 15 seconds

- Hydraulic clamping on casting datums

- Machine all features in single program

- Direct unload to finishing area

The kinematic fixture design uses casting features as primary datums rather than machined surfaces. Consequently, parts locate consistently despite casting variations. Hydraulic clamps then secure parts with 500 psi pressure for stability. Additionally, probe cycles verify part position before machining begins. This approach achieves ±0.02mm repeatability even after 5,000 cycles. When combined with advanced CNC machining service capabilities, 5-axis for die cast parts delivers unmatched precision and productivity.

Can You Really Achieve ±0.05mm Precision on Cast Parts?

Achieving tight tolerances on cast surfaces requires specific tooling strategies and cutting parameters. Traditional roughing operations often cause vibration and poor surface finish. However, trochoidal milling techniques distribute cutting forces evenly. Meanwhile, high-speed spindles enable surface speeds for magnesium.

Precision Machining Parameters:

- Tool: Ø6mm 3-flute carbide, 45° helix

- Speed: 18,000 RPM (350 m/min)

- Feed: 0.08 mm/tooth

- Depth: 0.3mm radial, 2.0mm axial

- Result: Ra 1.6μm surface finish

Thermal compensation systems account for machine growth during extended production runs. Specifically, laser measurement systems monitor critical dimensions throughout the cycle. Then, CNC controls automatically adjust tool positions to maintain accuracy. Additionally, coolant temperature regulation prevents thermal shock to workpieces. These combined systems achieve consistent ±0.05mm flatness on heat sink fins. When paired with professional surface finish techniques, automotive heat sink machining reaches new levels of quality. Furthermore, one-shot CNC finishing eliminates the need for secondary operations entirely.

Conclusion

The Contents of Conclusion

Die casting CNC finishing represents a practical solution for automotive manufacturers seeking improved productivity. By combining casting and machining operations, companies achieve 40% faster cycle times and 28% cost reductions. Moreover, AZ91D magnesium provides weight savings without sacrificing thermal performance. However, success requires proper safety protocols and fixture design. Therefore, manufacturers should evaluate their current processes and consider hybrid line integration.

The investment typically pays back within 14 months for medium-volume production. Furthermore, quality improvements reduce downstream assembly issues. As automotive lightweighting demands continue growing, die casting CNC finishing will become increasingly valuable. Start by analyzing your current heat sink production bottlenecks and calculating potential savings.

[External Links Recommendation]

[die casting CNC finishing automotive][^1]

[magnesium die casting CNC][^2]

[AZ91D hybrid manufacturing][^3]

[one-shot CNC finishing][^4]

[automotive heat sink machining][^5]

[5-axis for die cast parts][^6]

---

[^1]: Explore this link to understand how die casting CNC finishing enhances automotive manufacturing efficiency and quality.

[^2]: Discover the unique benefits of magnesium die casting CNC, including weight reduction and strength, which are crucial for modern manufacturing.

[^3]: Learn about AZ91D hybrid manufacturing to see how it combines materials for innovative solutions in various industries.

[^4]: Explore this link to understand how one-shot CNC finishing can enhance efficiency and precision in manufacturing processes.

[^5]: Discover best practices for automotive heat sink machining to improve thermal management and performance in vehicles.

[^6]: Learn how 5-axis machining can optimize the production of die cast parts, leading to better quality and reduced costs.