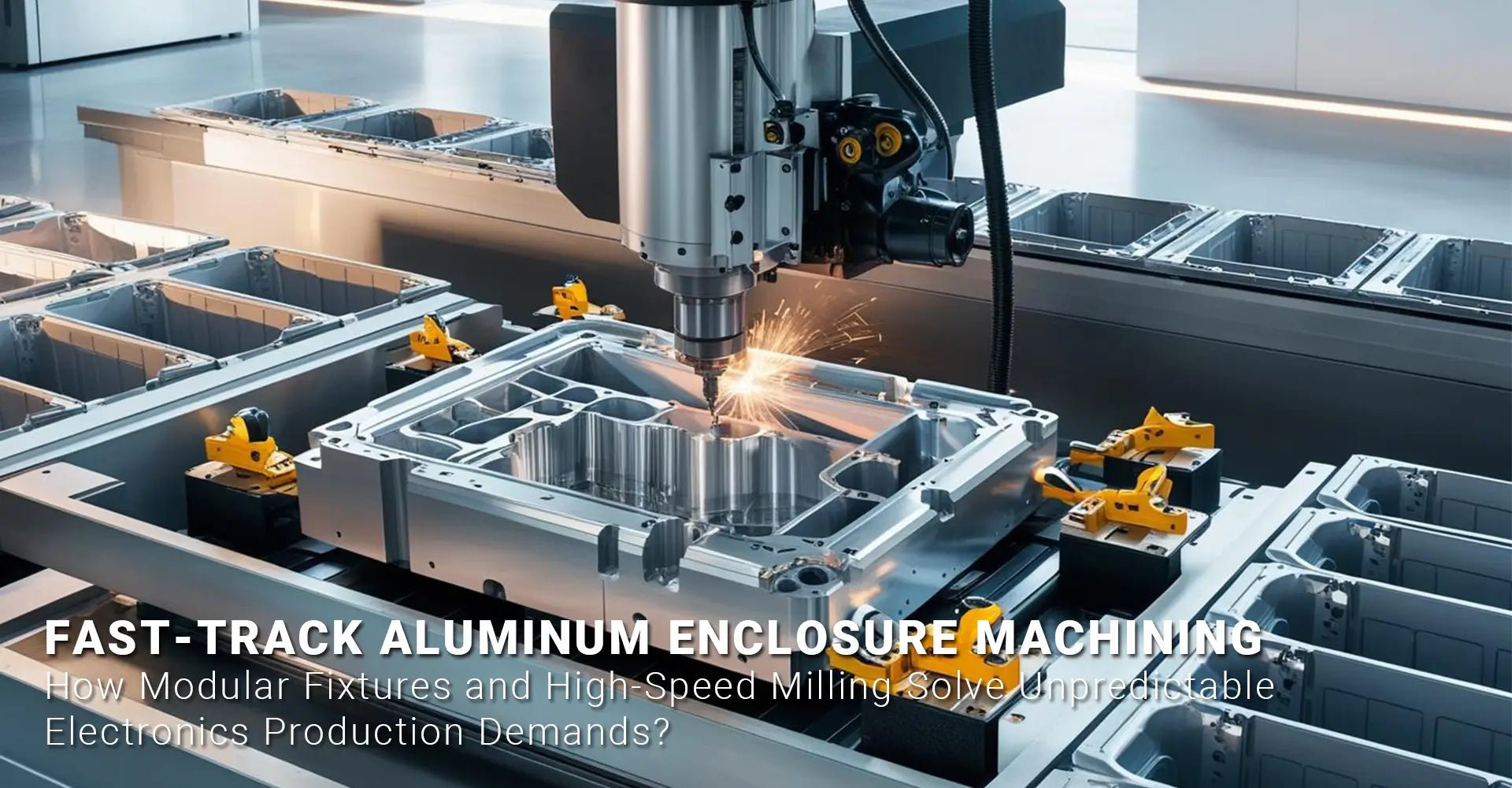

Fast-Track Aluminum Enclosure Machining: How Modular Fixtures and High-Speed Milling Solve Unpredictable Electronics Production Demands?

Fast-Track Aluminum Enclosure Machining: How Modular Fixtures and High-Speed Milling Solve Unpredictable Electronics Production Demands?

Can Your Machining Process Keep Pace with Unpredictable Electronics Orders?

In today's fast-paced electronics manufacturing landscape, demand volatility presents a significant challenge for precision machining operations. With consumer electronics companies frequently adjusting order quantities by up to 40% on short notice, traditional machining approaches simply can't keep up. The need for rapid batch machining for aluminum enclosures has never been more critical, especially when production schedules and profit margins depend on how quickly your facility can respond to changing client requirements.

Key Time-Saving Benefits at a Glance:

- 72-hour time savings per typical aluminum enclosure job

- 24-hour tooling readiness through standardized components

- Scalability from 100 to 10,000 units with minimal delay

- 60% lower upfront tooling investment costs

The combination of advanced fixturing techniques and optimized cutting parameters creates a production ecosystem that allows manufacturers to remain agile without sacrificing quality. Moreover, these approaches are particularly effective when working with aluminum—the material of choice for modern electronics housings due to its excellent thermal properties, weight advantages, and premium feel.

Before diving into the specific methodologies that make these impressive time savings possible, it's important to understand how modular fixtures and high-speed milling parameters work in tandem to create a responsive machining system. By embracing these techniques, electronics manufacturers can transform their production capacity from rigid and slow to flexible and fast.

Table of Contents

- How Does Quick-Change Tooling Cut 72 Hours From Each Production Job?

- What Makes Standardized Fixture Design the Key to 24-Hour Production Readiness?

- Why Are Pre-Tested Milling Parameters Critical for 6061/7075 Aluminum Success?

- How Did One Smart Speaker Manufacturer Achieve 500% Faster Production Ramp-Up?

- Conclusion

How Does Quick-Change Tooling Cut 72 Hours From Each Production Job?

The electronics manufacturing industry experiences some of the most dramatic order fluctuations in modern manufacturing. When a new smartphone or smart home device gains unexpected market traction, production requirements can surge overnight. Conversely, component shortages or market shifts can necessitate rapid production scaling adjustments. This volatile order response for electronics housings requirement puts immense pressure on machining operations.

Traditional tooling setups typically require extensive preparation time—from CAD/CAM programming to fixture fabrication and testing. However, implementing fast tooling changeover for batch production systems dramatically reduces these bottlenecks. With quick-change components, production teams can swap complete machining setups in under 30 minutes, compared to the 4-8 hours required with conventional methods.

The time savings accumulate across multiple production stages:

- Design Phase: Pre-designed fixture modules eliminate 16-24 hours of custom fixture design time

- Fabrication: No need to manufacture new fixtures from scratch (24-36 hours saved)

- Setup & Validation: Quick-lock mechanisms reduce machine setup time by 8-12 hours

When totaled across a typical production cycle, these efficiencies deliver approximately 72 hours (3 full days) of time savings per job. For electronics OEMs facing tight launch windows, this acceleration can mean the difference between meeting market demands or disappointing customers and retailers.

The quick-change approach particularly shines when machining complex aluminum enclosures with multiple features like precise I/O cutouts, cooling vents, and mounting points. Learn more about how custom CNC milling services can be optimized for electronics applications.

What Makes Standardized Fixture Design the Key to 24-Hour Production Readiness?

The development of modular fixture design for aluminum housings represents a paradigm shift in production planning. Traditional manufacturing requires custom fixtures for each new product design, creating significant delays when introducing new models or design variations. In contrast, standardized fixture systems can achieve production readiness in just 24 hours through clever engineering and reusable components.

The core concept centers around fixture systems where approximately 80% of components remain constant across different product runs. These standardized base plates, supports, and clamping mechanisms are designed with adjustability built in, allowing production teams to quickly configure them for new enclosure designs without starting from scratch.

A well-implemented modular fixture system includes:

- Universal Base Plates: Grid patterns that accommodate multiple workpiece sizes (50x50mm to 300x300mm)

- Adjustable Support Blocks: Quick-positioning elements that adapt to various enclosure geometries

- Standardized Clamping Mechanisms: Repeatable holding forces optimized for aluminum machining

- Quick-Connect Interfaces: Tool-less or minimal-tool fixture assembly and disassembly

The financial impact is equally impressive—modular tooling typically requires 60% lower initial investment compared to fully custom fixtures. This cost advantage compounds when producing multiple product variations or when designs undergo frequent revisions. The return on investment typically occurs after just three production batches (averaging 500 units each).

Additionally, these standardized fixture designs enable remarkably consistent part quality across batches, with holding repeatability of ±0.02mm for critical dimensions. This consistency is particularly valuable when manufacturing aluminum components in CNC machining processes where tight tolerances drive assembly quality and product performance.

Why Are Pre-Tested Milling Parameters Critical for 6061/7075 Aluminum Success?

Optimizing cutting parameters for aluminum machining has traditionally required extensive experimentation through trial runs, resulting in material waste, machine time consumption, and delayed production starts. The implementation of a pre-optimized milling parameter database eliminates this uncertainty by providing proven cutting values for specific aluminum grades and machining operations.

For common electronics enclosure materials like 6061-T6 and 7075-T6 aluminum, these optimized parameters typically include spindle speeds around 18,000 RPM, feed rates of 8 meters per minute, and stepovers of 0.3mm to achieve surface finishes of Ra 1.6μm without secondary operations.

The benefits of parameter libraries extend beyond time savings:

- Consistent Surface Finish: Achieve consumer-grade aesthetics directly from the milling process

- Extended Tool Life: Optimal cutting conditions reduce tool wear by up to 30%

- Reduced Energy Consumption: Efficient cutting parameters lower power requirements

- Predictable Machining Times: Accurate cycle time estimates for production planning

For electronics manufacturers, these pre-tested settings eliminate the guesswork that typically delays production starts. New parts can move directly to full production using parameter sets that have been proven on similar geometries and materials. This approach is particularly valuable when implementing high-speed milling solutions for consumer electronics, where both aesthetics and dimensional precision are non-negotiable requirements.

The parameter database becomes especially powerful when integrated with modern CAM systems, allowing for automated toolpath generation that incorporates these optimal cutting conditions. Manufacturers can further refine these parameters based on specific machine characteristics and tooling selections, building an increasingly valuable knowledge base with each production run.

For electronics manufacturers seeking deeper insights into aluminum machining techniques, exploring specialized electronics manufacturing resources can provide additional valuable information.

How Did One Smart Speaker Manufacturer Achieve 500% Faster Production Ramp-Up?

A leading smart speaker company faced a challenging production scenario when market demand for their new model exceeded forecasts by 300%. Their traditional manufacturing approach would have required weeks to scale production capacity, potentially missing the critical holiday shopping season. By implementing the modular fixture and optimized parameter approaches described above, they achieved remarkable results.

Their production team reduced total setup time from 3 days (72 hours) to just 8 hours—a 500% improvement in production ramp-up speed. This dramatic acceleration allowed them to begin shipping additional units within days rather than weeks.

The implementation followed a structured approach:

- Assessment Phase: Analyzed existing production bottlenecks (1 day)

- Modular Fixture Design: Created adaptable fixturing system for primary enclosure components (2 days)

- Parameter Optimization: Developed specific cutting parameters for their aluminum alloy (1 day)

- Implementation: Trained staff and executed the new production methodology (1 day)

The results extended beyond mere speed improvements. Product consistency improved measurably, with dimensional variance between parts reduced by 40%. Surface finish quality became more uniform, reducing post-processing requirements and cosmetic rejects. Perhaps most importantly, the manufacturer gained the ability to respond to order fluctuations without the anxiety and disruption typically associated with production scaling.

This case study highlights how ISO 9001-certified rapid machining services can maintain quality standards even while dramatically accelerating production timelines. The quality management systems ensured that despite the increased production speed, all components met the rigorous specifications required for consumer electronics products.

The approach also demonstrated how cost-effective aluminum enclosure manufacturing doesn't have to sacrifice quality or responsiveness. By implementing smarter production methodologies rather than simply adding more equipment or personnel, the manufacturer achieved both economic and performance advantages.

Conclusion

The ability to rapidly respond to changing production demands represents a significant competitive advantage in today's fast-paced electronics manufacturing landscape. By implementing modular fixture designs, quick-change tooling systems, and pre-optimized cutting parameters, manufacturers can achieve remarkable improvements:

- Setup time reductions of up to 72 hours per job

- Production readiness within 24 hours of receiving new designs

- Consistent quality across varying batch sizes

- Cost control even with order quantities fluctuating between 100-10,000 units

These approaches are particularly valuable for electronics manufacturers facing unpredictable market demands and tight launch windows. The technology and methodologies outlined here provide a clear pathway to enhanced manufacturing agility without requiring massive capital investments.

For electronics OEMs and contract manufacturers looking to improve their production responsiveness, the following steps offer a practical starting point:

- Audit current fixture designs to identify standardization opportunities

- Document and systematize cutting parameters for common aluminum grades

- Implement quick-change interfaces on existing equipment where possible

- Train production teams on modular fixture assembly and validation

By embracing these methodologies, manufacturers can position themselves as responsive, reliable partners in the demanding electronics supply chain. The resulting production agility doesn't just solve immediate challenges—it creates a sustainable competitive advantage in an industry where speed and flexibility increasingly determine success.

External Resources

[Rapid batch machining for aluminum enclosures][^1]

[High-speed milling solutions for consumer electronics][^2]

[Volatile order response for electronics housings][^3]

[Modular fixture design for aluminum housings][^4]

[ISO 9001-certified rapid machining services][^5]

[Cost-effective aluminum enclosure manufacturing][^6]

---

[^1]: Explore this link to understand how rapid batch machining can enhance efficiency and reduce costs in aluminum enclosure production.

[^2]: Discover cutting-edge high-speed milling solutions that can improve production speed and precision in consumer electronics manufacturing.

[^3]: Learn effective strategies to handle fluctuating orders in electronics housing production, ensuring timely delivery and customer satisfaction.

[^4]: Explore this link to understand how modular fixture design can enhance efficiency and precision in aluminum housing production.

[^5]: Learn about the significance of ISO 9001 certification and how it ensures quality in rapid machining services.

[^6]: Discover strategies and techniques that make aluminum enclosure manufacturing more affordable without compromising quality.

-

Posted in

High Speed CNC Milling