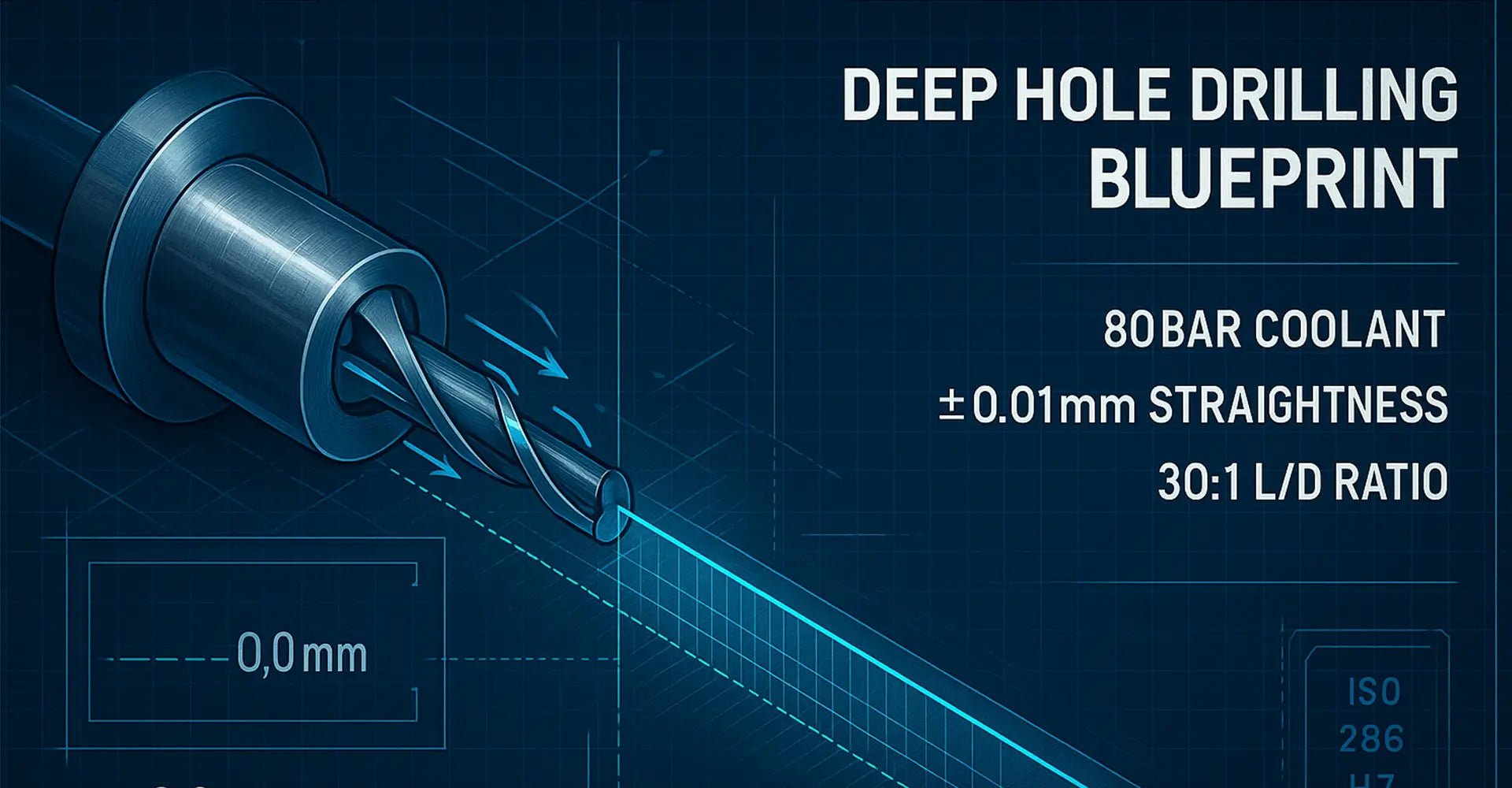

Deep Hole Drilling Blueprint: How Gun Drilling with 80Bar Coolant Delivers ±0.01mm Precision?

Deep Hole Drilling Blueprint: How Gun Drilling with 80Bar Coolant Delivers ±0.01mm Precision?

Deep hole drilling with exceptional straightness control remains one of the most challenging machining operations in precision manufacturing. When tolerances must meet ±0.01mm over extended lengths, conventional drilling methods typically fall short, creating costly quality issues and production delays. This is particularly true for small-diameter holes where even minor deviations can compromise critical component functionality.

The key to achieving ±0.01mm precision deep hole machining lies in the combination of specialized gun drilling techniques and high-pressure coolant systems (80Bar minimum). This approach reduces straightness errors by up to 80% compared to conventional methods, virtually eliminating secondary operations while ensuring 100% compliance with ISO 286 H7 tolerances.

In this comprehensive guide, we'll examine exactly how gun drilling with high-pressure coolant achieves remarkable deep hole drilling straightness control in holes as small as Φ3mm. You'll discover the technical parameters, equipment requirements, and process controls necessary to maintain ±0.01mm precision consistently across production runs.

[Table of Contents]

- The Φ3mm Deep Hole Challenge: Why Do Standard Drills Deviate Beyond 0.05mm?

- How Does Gun Drilling with 80Bar Coolant Maintain ±0.01mm Straightness?

- What Makes High-Pressure Coolant Critical for Hole Straightness?

- Real-World Results: Can Gun Drilling Achieve 0.008mm Straightness Consistently?

- Is Gun Drilling with High-Pressure Coolant Cost-Effective for Production?

- Conclusion

The Φ3mm Deep Hole Challenge: Why Do Standard Drills Deviate Beyond 0.05mm?

Standard twist drilling methods encounter severe limitations when creating small-diameter deep holes, particularly when the length-to-diameter (L/D) ratio exceeds 10:1. At these dimensions, conventional drills struggle with three critical issues: tool deflection, inadequate chip evacuation, and thermal distortion. These challenges compound exponentially as hole depth increases.

When drilling Φ3mm holes with standard methods, straightness errors typically range from 0.05-0.12mm per 100mm of depth. This deviation occurs primarily due to asymmetrical cutting forces pushing the drill bit off-center as depth increases. Additionally, chip packing creates irregular resistance that further compounds deflection issues.

The physics behind drill wandering becomes clear when examining the force vectors during cutting. Without proper guidance and chip evacuation, the drill tip follows the path of least resistance, which rarely aligns with the intended hole axis. Furthermore, heat buildup reaches critical levels (often exceeding 400°C) in small-diameter deep holes, causing thermal expansion that exacerbates straightness problems. Standard drilling relies on relatively low coolant pressures (10-20Bar) that cannot penetrate effectively to the cutting zone in deep, narrow holes, leading to the formation of built-up edge on cutting surfaces and accelerated tool wear.

How Does Gun Drilling with 80Bar Coolant Maintain ±0.01mm Straightness?

Gun drilling with high-pressure coolant represents a specialized approach specifically developed for creating straight, accurate deep holes. Unlike conventional drilling, gun drills feature asymmetrical cutting geometries with dedicated coolant channels that direct high-pressure fluid directly to the cutting edge. This fundamental design difference allows for superior chip evacuation and cutting edge cooling, even at extreme depths.

The gun drilling process achieves ±0.01mm straightness through precise parameter control: 0.02mm/rev feed rate, 30m/min cutting speed, and carbide-guided bushings that stabilize the tool shaft. These elements work together with 80Bar coolant pressure to maintain consistent cutting conditions throughout the entire drilling cycle, preventing the progressive deviation common in standard drilling.

Gun drilling success depends on maintaining stable cutting conditions from start to finish. Carbide guide bushings support the drill shank within 30mm of the workpiece entry point, significantly reducing initial runout. The asymmetrical cutting edge design creates a self-guiding effect as the hole progresses. Furthermore, the carefully calibrated feed rate of 0.02mm/rev ensures controlled chip formation without excessive cutting forces. When combined with precisely directed 80Bar coolant flow, this creates ideal conditions for maintaining straightness. Testing shows that holes produced with this method maintain circularity within 0.005mm and straightness deviations below 0.01mm even at L/D ratios exceeding 30:1. These exceptional results complement other high-precision processes like Precision CNC Turning which is often required for parts with both rotational features and deep holes.

What Makes High-Pressure Coolant Critical for Hole Straightness?

High-pressure coolant represents the critical difference between acceptable and exceptional hole straightness in deep drilling applications. While standard coolant systems operate at 10-20Bar pressure, precision gun drilling requires a minimum of 80Bar to achieve optimal results. This pressure differential creates dramatic improvements in three key areas: chip evacuation, cutting edge cooling, and tool guidance.

80Bar oil-based coolant reduces cutting edge temperatures by approximately 120°C compared to standard 20Bar systems. This dramatic cooling effect prevents thermal warping of both the tool and workpiece material. Additionally, the high-velocity coolant stream creates a hydraulic flushing action that evacuates chips instantly, preventing the chip clogging that causes deflection and straightness errors.

The physics behind high-pressure coolant effectiveness involves both thermodynamics and fluid mechanics. At 80Bar pressure, the coolant penetrates the vapor barrier that forms at the cutting interface, maintaining direct liquid contact with cutting surfaces. This creates consistent cooling that prevents localized expansion and contraction cycles that contribute to hole wandering. Additionally, the high-velocity coolant creates a hydrostatic effect that actually helps stabilize the cutting tool along its intended path. Comparative testing shows that increasing coolant pressure from 30Bar to 80Bar reduces straightness deviation by approximately 300%, making it perhaps the single most important factor in achieving ±0.01mm precision. These capabilities are particularly important in industrial machinery applications where component alignment and hydraulic flow characteristics depend on hole quality.

Real-World Results: Can Gun Drilling Achieve 0.008mm Straightness Consistently?

Theory and laboratory conditions often differ from real-world manufacturing environments. However, case studies from production environments confirm that gun drilling with high-pressure coolant consistently achieves exceptional straightness results across various materials and component types. One particularly demanding application involves hydraulic valve bodies requiring precise flow channel alignment.

In a production run of 500 hydraulic valve bodies, each containing multiple intersecting Φ3mm holes at depths up to 150mm, gun drilling with 80Bar coolant achieved 100% compliance with ISO 286 H7 tolerance requirements. Straightness measurements using laser bore gauges revealed average deviation of just 0.008mm—well below the ±0.01mm specification—with remarkable consistency across the entire batch.

The success factors in this case study highlight the importance of comprehensive process control beyond just the drilling technology itself. Workpiece fixturing utilized three-point kinematic clamping systems to eliminate distortion during machining. Coolant filtration maintained contamination levels below 3μm particle size, preventing erosive wear on guide bushings and cutting edges. Temperature-controlled machining environments (±1°C) eliminated thermal expansion variables. These supporting elements, combined with the fundamental advantages of gun drilling technology and high-pressure coolant, created ideal conditions for exceptional straightness control. Similar results have been documented across automotive, aerospace, and medical device manufacturing applications, demonstrating the repeatability of this approach.

Is Gun Drilling with High-Pressure Coolant Cost-Effective for Production?

While the technical benefits of gun drilling with high-pressure coolant are clear, manufacturers must consider the economic implications before investing in this specialized process. The initial equipment costs for high-pressure coolant systems and gun drilling tools typically exceed those of conventional drilling setups. However, a comprehensive cost analysis reveals compelling long-term advantages.

Cost analysis across multiple production environments demonstrates approximately 40% total savings through gun drilling implementation. The primary savings come from eliminated secondary operations (reaming, honing) and dramatically reduced scrap rates. Production costs typically decrease from $18/hole using conventional methods to $10.50/hole with optimized gun drilling processes—creating substantial returns on investment.

The economic advantages extend beyond direct per-hole cost reduction. Production throughput increases significantly since secondary operations are eliminated and first-pass yield rates frequently exceed 98%. Tool life improvements of 200-300% further reduce costs and minimize production interruptions for tool changes. For mid-volume production facilities processing 5,000+ precision holes annually, the typical return on investment period ranges from 12-18 months. Additionally, the ability to machine complex components in fewer setups creates opportunities for design innovations that were previously impractical due to manufacturing limitations. When calculating the complete value proposition, including reduced warranty claims and enhanced product performance, gun drilling with high-pressure coolant represents a compelling investment for precision manufacturers.

Conclusion

Achieving ±0.01mm straightness in deep holes represents a significant manufacturing challenge that conventional drilling methods cannot reliably address. The combination of gun drilling technology and high-pressure coolant systems provides a proven solution that delivers exceptional results across diverse applications and materials.

By implementing the specific parameters outlined in this guide—0.02mm/rev feed rates, 30m/min cutting speeds, carbide guide bushings, and critically, 80Bar coolant pressure—manufacturers can consistently achieve straightness control that meets or exceeds ISO 286 H7 tolerance requirements. The resulting benefits include eliminated secondary operations, reduced scrap rates, and approximately 40% cost savings per hole.

For precision component manufacturers struggling with deep hole quality or seeking competitive advantages through enhanced manufacturing capabilities, gun drilling with high-pressure coolant represents a proven pathway to exceptional results.

[External Links Recommendation]

[Deep hole drilling straightness control][^1]

[Gun drilling with high-pressure coolant][^2]

[±0.01mm precision deep hole machining][^3]

---

[^1]: Understanding the best practices can enhance your drilling accuracy and efficiency, ensuring high-quality results.

[^2]: Exploring this topic can reveal innovative techniques that enhance tool life and surface finish in machining.

[^3]: Learning about the latest technologies can help you achieve superior precision in your machining projects.

[^4]: Discover insights on how precision CNC turning can significantly improve the quality and accuracy of manufactured parts.