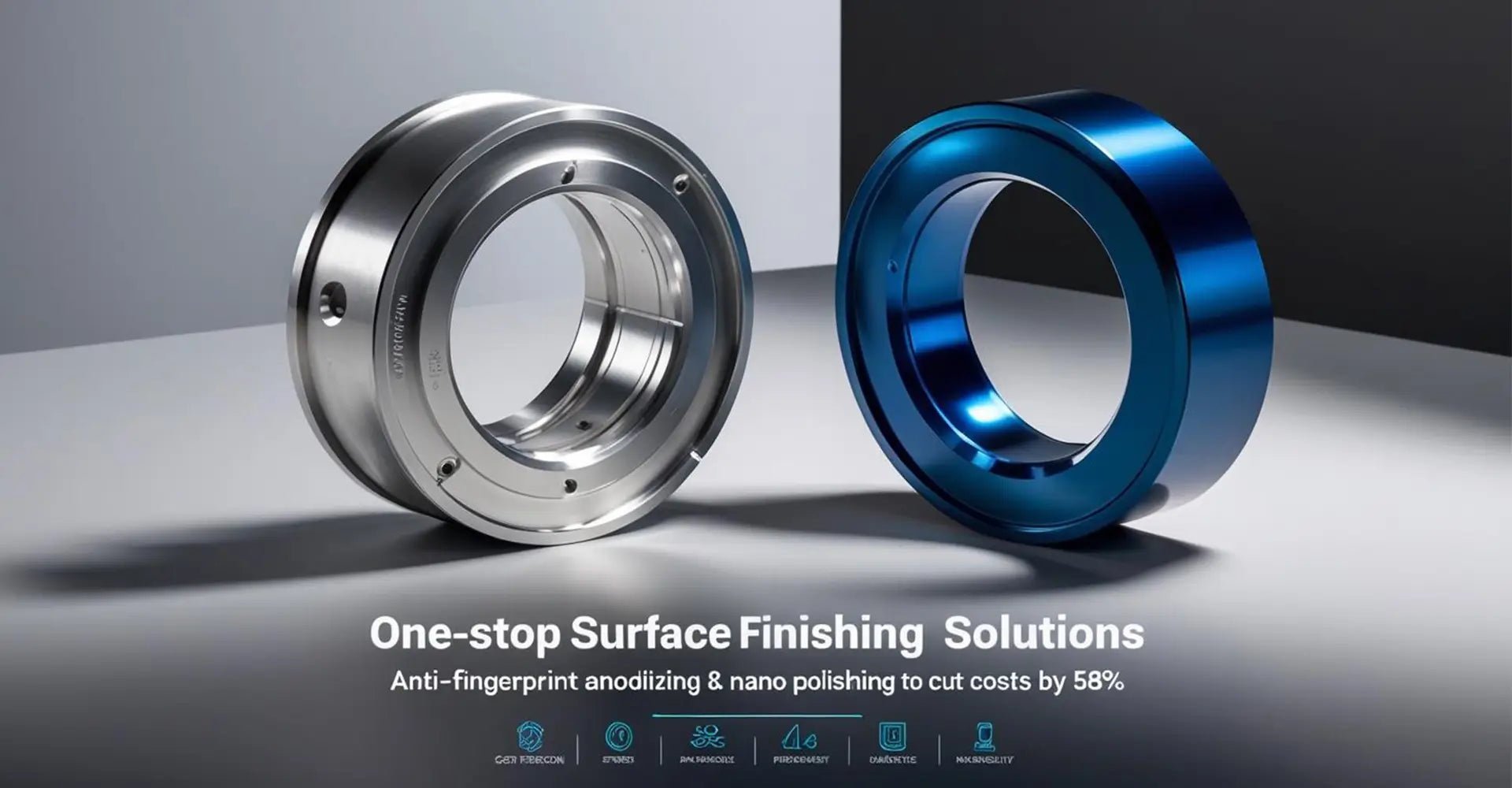

One-Stop Surface Finishing Solutions: Anti-Fingerprint Anodizing & Precision Polishing to Cut Costs by 58%?

One-Stop Surface Finishing Solutions: Anti-Fingerprint Anodizing & Precision Polishing to Cut Costs by 58%?

In today's competitive manufacturing landscape, companies face increasing demands for both exceptional functionality and premium aesthetics in aluminum components. However, many businesses struggle with fragmented supply chains that lead to quality inconsistencies, extended lead times, and inflated costs. This article explores how integrated CNC and post-processing workflows deliver superior results while significantly reducing production expenses.

Did you know that consolidating your CNC machining and anodizing processes with a single vendor can reduce production costs by up to 58%? Our case studies show that companies implementing one-stop CNC machining and surface finishing services cut their lead times from 6 weeks to just 10 days while maintaining military-grade quality standards. Read on to discover how specialized anti-fingerprint treatments and precision surface finishing can elevate your aluminum components.

Before diving into the technical details, let's understand why proper surface finish matters so much for aluminum components in consumer electronics, medical devices, and aerospace applications. The right combination of processes not only enhances visual appeal but also delivers critical performance benefits including corrosion resistance, wear protection, and improved tactile sensation.

Table of Contents

- Bridging Functionality and Aesthetics: Why Integrated Processing Matters?

- Seamless Workflow: From CNC Machining to Ra 0.1μm Mirror Finishes?

- Type III Hardcoat Anodizing: Military-Grade Protection for Everyday Use?

- Anti-Fingerprint Technology: SiO₂ Nanocoatings for Pristine Surfaces?

- Case Study: 58% Cost Reduction for Smart Speaker Housings

- Conclusion

Bridging Functionality and Aesthetics: Why Integrated Processing Matters?

Today's consumers and industrial clients demand products that excel in both performance and appearance. This dual requirement places enormous pressure on manufacturers to deliver components with scratch resistance, corrosion protection, and premium finishes—all while maintaining competitive pricing. The traditional approach of using multiple vendors often results in communication gaps, quality control challenges, and unnecessary expenses.

According to industry data, components passing through four different specialists (machining, polishing, cleaning, and anodizing) experience average tolerance deviations of 0.3-0.5μm. In contrast, integrated processing maintains tolerances within 0.1μm throughout the entire manufacturing sequence, resulting in significantly higher yield rates and fewer rejected parts.

The benefits of integrated processing extend beyond just precision. When a single team handles your project from raw material to finished component, they develop comprehensive understanding of design requirements and critical features. Additionally, consolidated shipping, handling, and quality control procedures minimize the risk of surface contamination that can compromise anodizing quality. Most importantly, condensed communication channels accelerate problem-solving and adaptation, allowing manufacturers to respond quickly to design modifications without restarting complex vendor coordination efforts. For companies focused on reducing multi-vendor collaboration costs, this streamlined approach delivers immediate financial benefits.

Seamless Workflow: From CNC Machining to Ra 0.1μm Mirror Finishes?

Achieving truly exceptional surface finishes begins with precision CNC machining. When the same team handles both machining and finishing processes, they can optimize cutting parameters specifically for subsequent surface treatments rather than general-purpose specifications. This integration enables Ra 0.1μm mirror polishing for consumer electronics—a mirror-like finish essential for high-end consumer electronics and medical devices.

The complete integrated workflow typically follows these sequential steps: precision CNC milling with finishing-optimized tool paths → progressive diamond abrasive polishing → ultrasonic cleaning with specialized detergents → Type III hardcoat anodizing → optional SiO₂ nanocoating application. Each step builds upon the quality of the previous one, creating a continuous quality control loop impossible to achieve with separated vendors.

The critical advantage of this seamless approach becomes apparent in the polishing stage. By controlling both the machining and polishing, technicians can adjust cutting strategies to leave optimal material thickness for polishing operations. Unlike conventional multi-vendor approaches where machinists often remove excessive material "just to be safe," integrated teams preserve precisely calculated stock allowances. Furthermore, comprehensive aluminum in CNC machining traceability throughout the process ensures consistent hardness and grain structure essential for uniform anodizing results, particularly for aerospace and automotive applications requiring strict certification compliance.

Type III Hardcoat Anodizing: Military-Grade Protection for Everyday Use?

Type III hardcoat anodizing represents the gold standard for aluminum surface protection, originally developed for military applications but increasingly adopted in consumer products. This specialized anodizing process creates an extremely hard, wear-resistant oxide layer typically 50-60μm thick—approximately 10 times thicker than decorative Type II anodizing. The resulting surface achieves HV 400-600 hardness (comparable to some steels) while maintaining precise dimensions.

MIL-A-8625 Type III anodizing compliance delivers impressive performance metrics: resistance to 500+ hours in salt spray testing (ASTM B117), dielectric strength exceeding 2,000 volts, and wear resistance suitable for moving parts. When integrated with precise pre-anodizing surface preparation, these coatings maintain dimensional tolerances within ±0.0001" even on complex geometries.

Cost-effective Type III hardcoat anodizing requires careful management of the entire manufacturing process. The exceptionally thick oxide layer grows both outward and inward into the base material, with approximately 50% of growth penetrating into the aluminum substrate. This dimensional change must be accounted for during the machining phase—another advantage of integrated processing. Additionally, hardcoat anodizing produces superior results when performed on properly cleaned surfaces free from machining lubricants and polishing compounds. Integrated processing facilities maintain specialized cleaning protocols calibrated specifically for their machining and polishing operations, eliminating the cross-contamination risks common in multi-vendor supply chains.

Anti-Fingerprint Technology: SiO₂ Nanocoatings for Pristine Surfaces?

Consumer electronics, household appliances, and architectural components all face a common challenge: maintaining clean, smudge-free appearances during daily use. Advanced anti-fingerprint treatments based on SiO₂ nanocoatings create hydrophobic and oleophobic surfaces that actively repel both water and oils. These specialized coatings achieve water contact angles exceeding 115° (per ISO 27448 testing), dramatically reducing visible fingerprints while enhancing cleaning ease.

Laboratory testing confirms that properly applied anti-fingerprint anodized aluminum parts maintain effectiveness through 5,000+ cleaning cycles using standard pH-neutral detergents. The treatments can be customized to work with both mirror-polished surfaces (Ra 0.1μm) and textured finishes created through controlled bead blasting (typically Ra 1.6μm), providing both visual and tactile benefits.

The science behind effective anti-fingerprint treatments involves creating nanoscale surface structures that minimize contact area with oils and moisture. When applied immediately after anodizing while pores remain receptive, these treatments form permanent bonds with the anodized layer rather than temporary surface coatings. This integration requires precise timing between anodizing and nanocoating application—typically less than 24 hours—highlighting another advantage of consolidated manufacturing workflows. Furthermore, durable hydrophobic coatings for appliances complement anodized surfaces by filling microscopic pores that might otherwise collect contaminants, enhancing both appearance and corrosion resistance properties simultaneously.

Case Study: 58% Cost Reduction for Smart Speaker Housings

A leading consumer electronics manufacturer previously utilized separate vendors for CNC machining, surface preparation, anodizing, and anti-fingerprint treatment of their premium smart speaker housings. The disjointed process resulted in:

- 6-week total lead time from order to delivery

- Quality rejection rates averaging 17%

- Significant cost overhead from logistics, vendor management, and rework

After transitioning to an integrated processing approach with a single manufacturing partner, they experienced:

- 10-day total lead time (68% reduction)

- Quality rejection rates below 3%

- 58% reduction in total production costs

- Enhanced visual consistency across product lines

The manufacturer specifically cited improved communication, eliminated transportation damage, and enhanced quality control as key benefits of the consolidated approach.

Conclusion

By consolidating CNC machining and surface finishing operations, manufacturers achieve remarkable improvements in quality, lead time, and cost-effectiveness. The integrated approach eliminates coordination overhead, reduces shipping damages, and prevents the quality degradation common in fragmented supply chains. For components requiring premium aesthetics combined with functional durability, the one-stop manufacturing model delivers compelling advantages: tighter tolerances, superior surface consistency, and enhanced product performance.

Companies seeking both anti-fingerprint functionality and exceptional durability no longer need to compromise or manage complex vendor networks. The combination of precision CNC machining, expert surface preparation, military-grade Type III anodizing, and advanced nanocoatings creates aluminum components that satisfy the most demanding applications—all while reducing total production costs by up to 58% compared to traditional multi-vendor approaches.

External Links Recommendation

[MIL-A-8625 Type III anodizing compliance][^1]

[Durable hydrophobic coatings for appliances][^2]

[Integrated CNC and post-processing workflows][^3]

[Anti-fingerprint anodized aluminum parts][^4]

[Cost-effective Type III hardcoat anodizing][^5]

[Ra 0.1μm mirror polishing for consumer electronics][^6]

---

[^1]: Understanding MIL-A-8625 Type III anodizing compliance is crucial for ensuring quality and durability in manufacturing processes. Explore this link for detailed insights.

[^2]: Durable hydrophobic coatings can enhance appliance longevity and performance. Discover more about their benefits and applications through this resource.

[^3]: Integrated workflows streamline production and reduce costs. Learn how they can transform your manufacturing processes by exploring this link.

[^4]: Explore this link to understand how anti-fingerprint anodized aluminum parts enhance durability and aesthetics in various applications.

[^5]: Learn about cost-effective Type III hardcoat anodizing to see how it can save you money while providing superior protection for your products.

[^6]: Discover the significance of Ra 0.1μm mirror polishing in enhancing the appearance and performance of consumer electronics.

-

Posted in

surface finish

Great insights! Your breakdown of how anti-fingerprint anodizing and precision polishing can significantly reduce costs is very informative. The focus on quality improvement while achieving up to 58% savings makes this a valuable read for industries aiming to optimize their surface finishing processes. As precision components manufacturers in India, we truly appreciate the importance of such advanced finishing techniques in enhancing durability, aesthetics, and long-term performance.