How Do You Prevent Clamp Marks on CNC Machined Parts?

How Do You Prevent Clamp Marks on CNC Machined Parts?

Have you ever completed an expensive machining job, only to discover ugly indentations where your vise gripped the part? You're not alone. Thousands of machine shops face this frustrating challenge every day, especially when working on high-end cosmetic components. Furthermore, as customer expectations for CNC machining surface quality continue to rise, traditional workholding methods often fall short. Therefore, understanding how to eliminate these defects has become essential for competitive manufacturing.

Quick Answer: How to Prevent Clamp Marks

To prevent clamp marks on machined parts, use one or more of these proven methods:

- Vacuum fixtures that distribute holding force across the entire surface

- Low-temperature adhesives that bond parts without mechanical pressure

- Soft jaws made from aluminum or plastic with protective inserts

- Repositioning clamps to non-visible or sacrificial surfaces

- Design modifications that include dedicated gripping features

Each method works best for specific part geometries, materials, and production volumes. As a result, choosing the right approach requires understanding your exact requirements.

Why This Problem Matters More in 2026

The demand for flawless surfaces has grown dramatically. Consequently, cosmetic defects that were once acceptable now cause parts to be rejected. Moreover, industries like consumer electronics, medical devices, and automotive manufacturing require absolutely pristine finishes. In addition, rework and polishing add significant costs that erode profit margins. Therefore, preventing marks during machining saves both time and money.

Table of Contents

- Why Do Vise Marks Appear on Machined Parts?

- Can Vacuum Fixtures Eliminate Contact Marks?

- How Does Adhesive Workholding Protect Cosmetic Surfaces?

- What Makes Soft Jaws Better for Surface Protection?

- Conclusion

Why Do Vise Marks Appear on Machined Parts?

Understanding the Physics Behind Fixture Marks

Clamp marks happen because of basic physics: pressure equals force divided by area. Standard steel vise jaws contact your part over a very small surface area. Consequently, even moderate clamping forces create extremely high pressure at those contact points. This pressure then exceeds the material's yield strength, causing permanent deformation.

The Root Cause of Surface Damage

Fixture marks on CNC parts occur when localized pressure surpasses material hardness limits. Aluminum, brass, and plastic parts are especially vulnerable because they're softer than steel jaws. Meanwhile, machinists must apply enough force to prevent part movement during cutting. As a result, they often overtighten clamps to ensure safety, which guarantees surface damage. Additionally, serrated or textured jaw surfaces concentrate force on even smaller points, making the problem worse.

When Surface Defects Become Critical Problems

Not all marks are equally problematic. However, marks become defects when they appear on visible "show faces" that customers will see. Furthermore, precision machining for cosmetic aluminum parts demands absolutely unmarked surfaces because even tiny indentations ruin the aesthetic appeal. Similarly, parts requiring specific surface finish grades cannot tolerate any deformation. In fact, a single visible mark can transform an expensive component into scrap.

The severity depends on several factors:

- Material hardness: Softer materials deform more easily

- Jaw geometry: Sharp edges concentrate pressure more than rounded surfaces

- Clamping force: Higher forces cause deeper impressions

- Part geometry: Thin walls and delicate features damage more readily

- Surface treatment: Anodizing or plating can't hide underlying deformation

Therefore, understanding these variables helps you predict when marks will occur and plan accordingly.

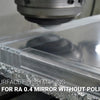

Can Vacuum Fixtures Eliminate Contact Marks?

How Vacuum Workholding Works

Vacuum fixturing represents a completely different approach to holding parts. Instead of gripping from the sides, a vacuum fixture for CNC machining pulls the part flat against a porous surface using atmospheric pressure. Consequently, the holding force distributes evenly across the entire contact area rather than concentrating at jaw points.

The Mark-Free Advantage

Vacuum systems eliminate clamp marks by spreading force over hundreds of square inches instead of a few square millimeters. This dramatic increase in contact area reduces pressure to levels far below what damages most materials. Moreover, the part sits against a smooth, flat surface rather than serrated metal jaws. As a result, even delicate cosmetic faces remain pristine throughout machining operations.

Design Considerations and Limitations

While vacuum fixtures excel at mark-free workholding CNC applications, they're not universal solutions. First, parts must have sufficient flat surface area to create an effective seal. Additionally, porous materials or parts with through-holes require special gaskets or sealing strategies. Furthermore, holding force depends on surface area and vacuum level, which limits their use for heavy cutting operations.

Key design factors include:

Surface requirements: The part needs at least one flat, smooth face for sealing. Therefore, curved or irregular surfaces may not work well.

Holding force calculations: Atmospheric pressure provides about 14.7 pounds per square inch at sea level. Consequently, a 10-inch-by-10-inch part yields approximately 1,470 pounds of theoretical holding force.

Safety margins: You should design for 3-5 times the expected cutting forces. Moreover, you must account for vacuum leaks and pressure variations.

Part flatness: Warped or non-flat parts won't seal properly. In addition, thin parts may deflect under vacuum, requiring support underneath.

Workholding for high cosmetic requirements: Vacuum excels here because it leaves absolutely no marks on visible surfaces. However, you must ensure adequate force for your specific cutting conditions.

Nevertheless, vacuum fixtures are particularly valuable for industrial machinery components requiring pristine surfaces on multiple faces.

How Does Adhesive Workholding Protect Cosmetic Surfaces?

Understanding Low-Temperature Adhesive Fixturing

Adhesive workholding bonds parts directly to fixture plates using specialized glues or tapes. Unlike mechanical clamps, this method applies no concentrated pressure points. Instead, the adhesive creates a uniform connection across the entire bonded surface. Therefore, even extremely delicate parts remain undamaged during machining.

Why Adhesives Outperform Clamps for Cosmetic Parts

Low-temperature adhesive fixturing provides the ultimate solution for protecting fully cosmetic components where even vacuum cups would leave marks. The adhesive layer cushions the part while distributing forces evenly. Additionally, modern formulations bond strongly enough to resist significant cutting forces while remaining removable with heat or solvents. Consequently, this approach works brilliantly for thin panels, decorative trim, and other parts where all surfaces must remain pristine.

Application Methods and Process Considerations

Successfully implementing adhesive fixturing requires careful attention to several factors. First, you must select an adhesive appropriate for your material and process temperatures. Moreover, surface preparation significantly affects bond strength, so parts must be clean and dry. Furthermore, you need adequate clamping pressure during cure time to ensure full contact.

Process workflow typically includes:

Surface preparation: Clean both the part and fixture plate thoroughly. Additionally, slightly roughening surfaces can improve adhesion for some materials.

Adhesive application: Apply a thin, even layer covering the entire contact area. However, avoid excessive thickness that could cause uneven bonding.

Part positioning: Place the part accurately before the adhesive sets. Therefore, you may need alignment fixtures or guides for precision.

Cure time: Allow sufficient bonding time according to adhesive specifications. Meanwhile, this adds to total cycle time, which you must account for in production planning.

Machining operations: Proceed with cutting while monitoring for any part movement or bond failure.

Debonding: Apply heat or solvent according to adhesive type. Consequently, some methods work faster than others.

Cleaning: Remove all adhesive residue from both the part and fixture. In addition, this step ensures parts meet cleanliness requirements.

The main trade-off involves cycle time. Nevertheless, for high-value cosmetic work, the elimination of rework often justifies the additional process steps. This method particularly suits no-mark clamping methods requirements.

What Makes Soft Jaws Better for Surface Protection?

The Soft Jaw Concept

Soft jaws are custom-machined clamping surfaces made from materials softer than the workpiece. Typically machined from aluminum, plastic, or even wood, these jaws can be shaped precisely to match your part's geometry. Consequently, they increase contact area while reducing surface pressure. Moreover, their softer material yields rather than damaging the part if over-tightened.

How Soft Jaws for Cosmetic Surfaces Protect Parts

Soft jaws prevent damage by spreading clamping force over a much larger area than standard steel jaws. Instead of two narrow contact lines, properly designed soft jaws can grip along entire part faces. Therefore, the pressure drops to safe levels even with significant clamping force. Additionally, the softer jaw material acts as a buffer that absorbs force without transmitting full pressure to the part. As a result, protecting machined surfaces from clamp dents becomes much easier.

Design Strategies and Material Selection

Creating effective soft jaws requires thoughtful design beyond simply using softer material. First, you must analyze where and how to grip the part for maximum contact. Moreover, the jaw geometry should match the part profile precisely to avoid point contacts. Furthermore, incorporating protective pads or inserts adds an extra layer of surface protection.

Material choices include:

Aluminum soft jaws: Easy to machine and sufficiently soft for most applications. However, they still provide good rigidity and durability. Therefore, they're the most common choice for how to avoid vise marks on machined parts.

Plastic jaws: Made from materials like Delrin or nylon, these offer even softer contact. Additionally, they work well for very delicate surfaces. Nevertheless, they wear faster than aluminum.

Rubber or urethane inserts: Bonded or mechanically attached to aluminum jaws, these provide the best surface protection. Moreover, they conform slightly to part irregularities for better contact.

Sacrificial layers: Thin sheets of soft material (copper, brass, or plastic) placed between jaws and part. Consequently, they take the marking instead of your expensive component.

Design best practices:

- Maximize contact area by matching jaw profile to part geometry

- Avoid sharp corners or edges that concentrate force

- Include grooves or pockets for inserting protective pads

- Design for easy replacement as jaws wear

- Consider multiple jaw sets for different part features

Therefore, investing time in proper soft jaw design pays dividends in reduced scrap and rework. This approach particularly benefits CNC machining service providers working with demanding customers.

Conclusion

Eliminating clamp marks on machined parts requires matching your fixturing method to part requirements. Vacuum fixtures excel for flat panels requiring mark-free surfaces, while adhesive workholding provides the gentlest possible support for fully cosmetic components. Meanwhile, soft jaws offer a practical middle ground that works for many geometries without requiring specialized equipment.

The key is planning ahead rather than reacting after discovering damaged parts. Therefore, consider CNC workholding for high cosmetic requirements during the design phase. Additionally, communicate clearly with your machinist about which surfaces must remain pristine. Finally, remember that investing in better fixturing usually costs less than rework, scrap, and lost customer confidence.

By implementing these proven techniques, you can consistently deliver parts with flawless surfaces that meet the most demanding specifications. Consequently, your shop's reputation for quality will grow along with customer satisfaction.

Recommended Resources

[CNC machining surface quality][^1]

[mark-free workholding CNC][^2]

[vacuum fixture for CNC machining][^3]

[soft jaws for cosmetic surfaces][^4]

[How to avoid vise marks on machined parts][^5]

[Low-temperature adhesive fixturing][^6]

--------

[^1]: A 2026 guide on surface roughness indicators ($Ra$, $Rz$, $RMS$). It explains the cost-to-quality ratio and recommended applications for different roughness levels in aerospace and medical industries.

[^2]: This resource details advanced clamping solutions, including hydraulic and vacuum systems, specifically focusing on how to maintain part integrity and avoid surface damage during high-speed machining.

[^3]: A technical breakdown of using vacuum tables for high-speed machining. It covers "onion skinning" techniques and the use of sacrificial VacuCard to maintain a mark-free bottom surface during full-depth milling.

[^4]: A foundational guide on designing and machining soft jaws. It explains how to create inverse pockets in aluminum to grip complex, pre-finished parts without deforming or scratching the cosmetic faces.

[^5]: A 2026 technical analysis of CNC defects, specifically covering how to prevent "vise rash" and clamping deformation through optimized fixture alignment and pressure compensation.

[^6]: A detailed breakdown of "zero-force" clamping. It compares vacuum tables, magnetic chucks, and adhesive fixturing for thin-walled components where surface integrity is critical.