What Is Fixtureless 5-Axis Machining and Should Your Shop Adopt It?

What Is Fixtureless 5-Axis Machining and Should Your Shop Adopt It?

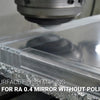

Fixtureless 5 axis machining is changing how CNC shops handle complex parts. Instead of designing custom fixtures or wrestling with clamps and vises, this approach uses vacuum fixturing CNC systems or magnetic workholding CNC technology to secure workpieces directly to the machine table. By eliminating physical obstructions, you gain complete access to five sides of your part in a single setup. This method dramatically cuts setup time, reduces tooling costs, and opens new possibilities for complex geometries that would be nearly impossible to fixture conventionally.

Quick Answer: Fixtureless 5-axis machining uses vacuum plates or magnetic chucks instead of traditional fixtures to hold parts during machining. This works best for parts with flat bases—like enclosures, panels, and brackets—and can reduce setup time by 60-80% while maintaining precision through probing cycles and careful force calculation.

However, not every part is suitable for this approach, and jumping in without understanding the risks can lead to expensive crashes or ruined workpieces. Therefore, let's explore exactly when fixtureless manufacturing makes sense, how to choose between vacuum and magnetic systems, and what precautions you need to take to implement this successfully in your shop.

Table of Contents

- Which Parts Work Best for Fixtureless 5-Axis Machining?

- How Do You Choose Between Vacuum and Magnetic Workholding?

- What Are the Real Risks and How Can You Prevent Them?

- How Much Time and Money Can Fixtureless Machining Actually Save?

Which Parts Work Best for Fixtureless 5-Axis Machining?

Not every component is a good candidate for fixtureless manufacturing process implementation. Consequently, understanding which geometries benefit most from this approach will save you time and prevent costly mistakes. The ideal parts share certain characteristics that make them naturally suited to vacuum or magnetic holding.

Best candidates include:

- Thin-walled enclosures that distort under clamp pressure

- Large flat panels needing five-side access

- Cubic parts with complex features on multiple faces

- Non-ferrous brackets with substantial flat bases

- Plastic prototypes requiring gentle, even pressure

- Sheet metal components before forming operations

- Mounting plates requiring precise, flat datums

- Parts with 3D contours where clamps would interfere

- Large discs and rotors (for magnetic applications)

- Components with shallow undercuts accessible via tilt

The common thread among these geometries is a large, relatively flat base that creates proper contact with the workholding surface. For vacuum fixturing, this means you need a non-porous material like aluminum, plastic, or sealed composite that can maintain an airtight seal. Meanwhile, magnetic chucks require ferromagnetic materials such as steel or cast iron. Parts with extensive surface area relative to cutting forces work exceptionally well because the distributed holding force prevents distortion. Additionally, components requiring access to five sides benefit enormously since the 5 axis machining fixtures don't obstruct toolpaths. This combination of accessibility and gentle, uniform clamping pressure makes fixtureless methods particularly valuable for aerospace enclosures, medical device housings, and automotive structural components where traditional clamping would either damage the part or require multiple complex setups. Moreover, rapid prototyping applications benefit significantly because you can iterate quickly without investing time in custom fixture fabrication. For shops working with CNC metals and plastics, this approach opens up possibilities that were previously cost-prohibitive for low-volume production runs.

How Do You Choose Between Vacuum and Magnetic Workholding?

Once you've determined your part is suitable for fixtureless machining, the next critical decision is selecting between vacuum plate 5 axis machining and magnetic chuck precision milling. Both technologies eliminate traditional fixtures, but they serve different materials and applications. Understanding their strengths will help you invest wisely.

Comparison Table:

| Factor | Vacuum Fixturing | Magnetic Workholding |

|---|---|---|

| Best Materials | Aluminum, plastics, composites (non-porous) | Steel, cast iron, ferromagnetic metals |

| Key Strength | Prevents distortion in thin-walled parts | Instant, extremely strong holding force |

| Setup Speed | Seconds (place part and activate pump) | Instantaneous (flip switch) |

| Force Distribution | Uniform across entire contact area | Concentrated at magnetic pole locations |

| Main Limitation | Requires seal; force drops with part size | Only works with magnetic materials |

| Maintenance | Pump, seals, and surface flatness checks | Minimal; watch for residual magnetism |

For shops working primarily with aluminum aerospace components or plastic prototypes through CNC machining services, vacuum fixturing CNC systems offer unmatched versatility. The distributed force prevents warping in thin-walled sections, and modern vacuum pumps provide consistent holding across varying part sizes. On the other hand, if your shop machines steel molds, cast iron engine blocks, or ferrous structural parts for industrial machinery, magnetic workholding CNC delivers instant clamping with incredible strength—often exceeding 100 pounds per square inch of contact. Moreover, magnetic systems have virtually no consumables since there are no pumps or seals to maintain. However, you must demagnetize parts after machining to avoid interference with downstream assembly operations. For shops handling mixed materials, modular vacuum plates with removable sections provide the greatest flexibility, allowing you to configure the holding area based on each specific part geometry. Additionally, some advanced systems combine both technologies on a single table, giving operators the ability to switch methods without changing equipment. This workholding innovation CNC shop owners are adopting represents a significant shift from traditional soft jaw alternative 5 axis approaches that required extensive setup and adjustment time.

What Are the Real Risks and How Can You Prevent Them?

While fixtureless machining offers compelling advantages, it also introduces risks that traditional fixtures minimize through physical constraint. Specifically, part dislodgement, positioning errors, and collision with the workholding surface are genuine concerns. Nevertheless, these risks can be managed effectively through proper planning and smart safety measures.

Three Primary Risks:

-

Part Dislodgement – Workpiece shifts or becomes projectile during cutting

- Prevention: Calculate required force based on your deepest cut and fastest feedrate; use vacuum switches that trigger emergency stops if pressure drops

-

Positioning Inaccuracy – Loss of precise datum without physical locators

- Prevention: Add locating pins or fences to your plate; always probe part position after clamping

-

Tool Collision – Cutting tool or spindle crashes into workholding surface

- Prevention: Model your vacuum plate or magnetic chuck in CAM software; simulate complete toolpath with collision detection active

Calculating holding force is straightforward but critical. First, determine your maximum cutting force by considering your largest depth of cut, widest tool, and highest feedrate—conservative estimates suggest aluminum face milling can generate 200-400 pounds of force. Then, calculate your available vacuum force using the formula: Force = Area × Pressure × 0.85 (safety factor). For example, a 10-inch by 8-inch part (80 square inches) with 20 inches of mercury vacuum provides approximately 680 pounds of holding force—more than sufficient for most operations. For magnetic chucks, manufacturers specify holding force per square inch, but you must ensure full contact across the entire part base. Furthermore, positioning accuracy requires a hybrid approach. Although vacuum and magnetic systems lack the mechanical stops of traditional fixtures, you can incorporate simple locating features—two pins at 90 degrees establish X and Y datum reliably. Then, use your machine's touch probe to verify part location and create an accurate work offset. This approach combines the speed of fixtureless holding with the precision of measured positioning. Finally, always run your first program at 10% feedrate with rapid override engaged, watching carefully for any unexpected movement or vibration. This disciplined approach to CNC fixture design ensures that you maintain the quality standards your customers expect while gaining the speed advantages of fixtureless methods.

How Much Time and Money Can Fixtureless Machining Actually Save?

The financial case for fixtureless machining extends beyond eliminating fixture design costs. In fact, the time savings across the entire production cycle often deliver the most significant ROI. Let's examine real numbers to understand what you can realistically expect.

Time Savings Breakdown:

- Fixture design & manufacturing: 2-4 weeks → 0 hours (eliminated)

- Setup time per part: 15-30 minutes → 2-5 minutes (80% reduction)

- Engineering changes: Requires new fixture → Update program only (days saved)

- First-piece inspection: Slower due to fixture complexity → Faster with probe verification

- Typical ROI timeframe: 6-12 months for shops running 20+ setups monthly

Consider a real-world example from a medical device manufacturer machining aluminum enclosures. Previously, each new enclosure design required a custom soft jaw set that took three days to design, two days to machine, and cost approximately $800 in materials and labor. Setup time per part averaged 22 minutes, and any design revision meant modifying or recreating the fixture. After implementing a vacuum plate system, setup dropped to under 4 minutes—just place the part, activate vacuum, probe, and run. The $3,200 investment in a quality vacuum plate paid for itself after just four fixture eliminations. More importantly, the shop gained agility to respond to customer design changes within hours instead of weeks. Additionally, fixtureless thinking changes your approach to job quoting. You can competitively bid on small-batch custom work that would have been unprofitable with traditional fixturing overhead. Furthermore, machine utilization improves because operators spend less time on setup and more time cutting chips. For shops looking to stay competitive, fixtureless methods represent not just cost savings but strategic capability that opens new market opportunities and strengthens customer relationships through faster turnaround. This is particularly valuable for businesses offering comprehensive manufacturing solutions where speed and flexibility directly impact customer satisfaction.

Conclusion

Fixtureless 5-axis machining using vacuum and magnetic workholding represents a practical solution for shops looking to reduce setup time, lower tooling costs, and handle complex geometries with greater efficiency. However, success requires careful part selection, proper force calculation, and disciplined risk management. Start with ideal candidates—parts with large, flat bases and complex five-side features—and implement safety measures like vacuum monitoring and positioning probes. The technology works best when you combine it with thorough CAM simulation and conservative first-run parameters. For shops already running 5-axis equipment, the investment in quality vacuum or magnetic workholding pays back quickly through eliminated fixture costs and dramatically reduced setup times. Most importantly, this approach gives your shop the flexibility to respond rapidly to design changes and competitively quote smaller batches that would be unprofitable with traditional fixturing.

External Links & Resources

[fixtureless 5 axis machining][^1]

[vacuum fixturing CNC][^2]

[magnetic workholding CNC][^3]

[fixtureless manufacturing process][^4]

[magnetic chuck precision milling][^5]

[workholding innovation CNC shop][^6]

---

[^1]: Explore this link to understand how fixtureless 5 axis machining can enhance efficiency and precision in manufacturing.

[^2]: Learn about vacuum fixturing in CNC to discover its advantages for holding complex parts securely during machining.

[^3]: Discover how magnetic workholding CNC systems can enhance precision and efficiency in machining processes.

[^4]: Learn about fixtureless manufacturing processes that can reduce setup time and increase flexibility in production.

[^5]: Discover how magnetic chucks enhance precision in milling, improving efficiency and accuracy in your machining processes.

[^6]: Explore cutting-edge workholding solutions that can optimize your CNC operations and boost productivity.