How Does Bead Blasting Achieve Ra 0.1 to Ra 0.8 Surface Finishes?

How Does Bead Blasting Achieve Ra 0.1 to Ra 0.8 Surface Finishes?

Are you struggling to achieve consistent surface finishes on your metal parts? Whether you're restoring vintage car panels or finishing precision CNC components, understanding how bead blasting controls surface roughness can save you time and money. This comprehensive bead blasting surface finish guide reveals the exact parameters you need to master.

Quick Answer: Key Factors That Control Your Surface Finish

| Factor | Impact on Ra Value | Recommended Range |

|---|---|---|

| Media Type | Glass beads = smoother (Ra 0.4-0.8) | 80-220 mesh for precision |

| Air Pressure | 40-100 PSI range | Lower = smoother finish |

| Blasting Distance | 4-12 inches optimal | Closer = more aggressive |

| Media Hardness | Mohs 5-6 for fine work | Softer = less material removal |

Getting the right surface finish starts with understanding these four critical variables. Moreover, selecting the proper combination ensures repeatable results across production runs.

The following sections break down each factor in detail. Therefore, you'll learn exactly how to control surface roughness with bead blasting for any application.

Table of Contents

- What Makes Glass Bead Blasting Different from Aluminum Oxide Grit Blasting?

- Which Parameters Control Surface Roughness in Bead Blasting?

- What Are the Best Applications for Glass Bead Blasting?

- How Can You Calculate Bead Blasting Cost Per Part?

- Conclusion

What Makes Glass Bead Blasting Different from Aluminum Oxide Grit Blasting?

Choosing between different abrasive blasting media selection options can feel overwhelming. However, the decision becomes simple once you understand how media shape and hardness affect your results.

The Core Differences: Shape, Hardness, and Action

When comparing glass beads vs aluminum oxide blasting, three key properties stand out:

Glass Beads:

- Spherical, smooth particle shape

- Mohs hardness rating of 5-6

- Creates satin or matte finish bead blasting results

- Reusable up to 30 times in cabinet systems

- Acts through peening rather than cutting

Aluminum Oxide:

- Angular, sharp particle edges

- Mohs hardness rating of 8-9

- Produces aggressive cutting action

- Creates textured, profiled surfaces

- Ideal for coating adhesion preparation

Understanding the Bead Blasting vs Grit Blasting Difference

The fundamental distinction lies in how each media interacts with your workpiece. First, glass bead blasting uses spherical particles that bounce off the surface. As a result, this creates a peening effect that smooths and polishes without removing significant material. In contrast, aluminum oxide grit contains sharp edges that cut into the substrate.

For instance, when working with aluminum parts, glass beads produce surface finish Ra values between 0.4 and 0.8 micrometers. Meanwhile, aluminum oxide typically generates rougher profiles ranging from 1.5 to 4.0 micrometers. This makes glass beads the preferred choice when you need non-destructive blasting media that preserves dimensional accuracy.

Additionally, the economic factor matters significantly. Because glass beads maintain their shape longer, they offer better value for repetitive finishing work. On the other hand, aluminum oxide breaks down faster but excels at removing stubborn coatings and rust.

Most importantly, selecting the right media depends on your specific goal. Therefore, use glass beads for finishing, cleaning, and decorative applications. Conversely, choose aluminum oxide when you need aggressive material removal or surface profiling for paint adhesion.

Which Parameters Control Surface Roughness in Bead Blasting?

Achieving precise bead blasting parameters for Ra finish requires mastering three interconnected variables. Furthermore, understanding their relationships helps you dial in consistent results every time.

The Three-Factor Control System

Media Size:

- 80-120 mesh produces Ra 0.4-0.6 micrometers

- 120-220 mesh achieves Ra 0.1-0.4 micrometers

- Finer particles create smoother finishes

Air Pressure:

- 40-60 PSI delivers smooth, polished surfaces

- 60-80 PSI provides balanced cleaning and finishing

- 80-100 PSI offers aggressive material removal

Blasting Angle:

- 90° angle maximizes impact and material removal

- 45-60° angle creates gentler polishing action

- Shallow angles reduce surface profile depth

How Each Parameter Affects Your Final Finish

Let's start with media size, which represents the most critical factor in this equation. Specifically, larger particles (lower mesh numbers) impact the surface with more force. Consequently, they remove more material and create deeper valleys in the surface profile. Meanwhile, finer particles (higher mesh numbers) produce gentler impacts that result in smoother finishes.

Next, air pressure determines impact velocity. For example, increasing pressure from 40 to 80 PSI can change your Ra value from 0.3 to 0.7 micrometers when using the same media. Therefore, always start with lower pressure and gradually increase until you achieve the desired result.

Distance plays an equally important role in the process. Holding the nozzle 4 inches from the surface concentrates the blast pattern. In contrast, positioning it 12 inches away spreads the impact over a larger area. As a result, closer distances create more aggressive finishes.

When working on CNC machined parts, precise parameter control becomes essential. For instance, aluminum components requiring Ra 0.4 finishes typically need 100-140 mesh glass beads at 50-60 PSI. However, stainless steel might require slightly higher pressure due to its greater hardness.

Here's a practical example for glass bead blasting for aluminum:

- Target: Ra 0.5 micrometers, uniform matte appearance

- Media: 120 mesh glass beads

- Pressure: 55 PSI

- Distance: 8 inches

- Angle: 70-80 degrees

- Pass Speed: Slow, overlapping strokes

Similarly, achieving smoother finishes on steel requires adjusting these parameters. Specifically, you might use 140 mesh media at 45 PSI with 10-inch standoff distance. Meanwhile, removing light oxidation demands more aggressive settings.

Remember that material hardness affects the outcome significantly. Softer metals like aluminum respond quickly to blasting. Therefore, they require gentler parameters than harder materials like tool steel. Additionally, work hardening can occur with excessive pressure, so monitor your results carefully.

What Are the Best Applications for Glass Bead Blasting?

Glass bead blasting serves diverse industries requiring precise surface preparation. Moreover, its versatility makes it indispensable for both restoration projects and manufacturing processes.

Top Four Applications Where Glass Beads Excel

Automotive Restoration Bead Blasting:

- Removes paint layers without warping thin body panels

- Cleans engine components without dimensional changes

- Prepares surfaces for powder coating

- Reveals original metal texture safely

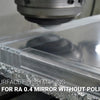

CNC Machined Parts Finishing:

- Creates uniform matte surfaces on precision components

- Removes machining marks and tool marks

- Maintains tight tolerances (±0.001 inch typical)

- Prepares parts for anodizing or coating

Precision Cleaning Operations:

- Eliminates light oxidation and surface contaminants

- Cleans complex geometries and internal passages

- Removes heat treat scale gently

- Prepares medical device components

Surface Preparation for Coating:

- Generates ideal anchor profile for paint adhesion

- Creates consistent surface energy

- Removes oils and residues

- Profiles substrates for powder coating

Real-World Case Studies and Results

Starting with automotive restoration, classic car enthusiasts face a common challenge. Specifically, they need to strip decades of paint without damaging original metal. Traditional chemical stripping can be messy and time-consuming. However, glass bead blasting offers a cleaner alternative.

For example, restoring a 1967 Mustang fender typically requires these specifications:

- Media: 80-100 mesh glass beads

- Pressure: 60-70 PSI

- Coverage Rate: Approximately 2-3 square feet per minute

- Result: Clean, ready-to-prime surface with Ra 0.6-0.8

Meanwhile, industrial machinery components benefit from different parameters. Large hydraulic parts often need thorough cleaning without surface damage. In this case, operators use 60-80 mesh beads at 70-80 PSI to remove heavy contamination quickly.

Precision manufacturing presents another compelling use case. When producing aerospace components, maintaining dimensional accuracy remains critical. Therefore, manufacturers rely on controlled glass bead blasting to achieve specified surface finishes. For instance, aluminum aircraft brackets often require Ra 0.4-0.6 finishes before anodizing.

Here's why glass bead blasting outperforms alternatives in these scenarios:

First, it provides non-contact cleaning that reaches complex geometries. Second, the process generates minimal heat, preventing material distortion. Third, glass beads won't embed in softer metals like aluminum or brass. Finally, the method produces consistent, repeatable results across production batches.

Additionally, medical device manufacturing relies heavily on precise surface preparation. Surgical instruments require extremely clean, uniform surfaces. Consequently, manufacturers use fine 140-220 mesh beads at low pressure (40-50 PSI) to achieve biocompatible surface conditions.

The decorative finishing market also depends on glass bead capabilities. Architectural hardware, consumer electronics housings, and jewelry all benefit from the uniform satin finish that only spherical media can provide. Furthermore, this aesthetic consistency cannot be replicated through manual methods.

How Can You Calculate Bead Blasting Cost Per Part?

Understanding the economics of bead blasting helps you make informed decisions about equipment investment. Furthermore, accurate cost calculation ensures competitive pricing for your services.

Cost Breakdown Per 100 Parts

Media Costs:

- Initial purchase: $40-60 per 50-pound bag

- Reusability factor: 30 cycles average

- Effective cost per cycle: $15-25 per 100 parts

Compressed Air Costs:

- Typical consumption: 15-25 CFM at 80 PSI

- Energy cost: $8-12 per operating hour

- Efficiency varies with compressor type

Labor Costs:

- Process time: 2-5 minutes per medium part

- Operator rate: $20-35 per hour

- Setup and changeover time included

Total Estimated Cost:

- Small parts (under 6 inches): $0.30-0.80 each

- Medium parts (6-12 inches): $0.50-1.50 each

- Large parts (over 12 inches): $1.50-4.00 each

Factors That Impact Your Bottom Line

Part size represents the most obvious cost driver. Larger components require more media, longer processing time, and greater air consumption. For instance, blasting a small bracket might take 90 seconds. In contrast, finishing a large housing could require 8-10 minutes.

Complexity also affects processing time significantly. Parts with intricate details, blind holes, or multiple angles demand more attention. Therefore, operators must move more slowly and adjust their technique frequently. As a result, labor costs increase proportionally.

The desired finish quality directly impacts both time and media consumption. Achieving Ra 0.2 requires finer media and multiple passes. Meanwhile, Ra 0.8 finishes need fewer passes with coarser media. Consequently, smoother finishes cost more to produce.

Batch size dramatically affects per-part economics. Running 500 identical parts allows for optimized setup and efficient media recycling. However, processing five different part types in small quantities increases changeover time. Therefore, larger production runs offer better unit costs.

Here's a practical calculation for the bead blasting cost per part scenario:

Example: 100 Aluminum Brackets (4x6 inches each)

- Media cost (recycled 25 times): $18

- Compressed air (2.5 hours at $10/hour): $25

- Labor (2.5 hours at $28/hour): $70

- Equipment depreciation: $12

- Total cost: $125 for 100 parts = $1.25 per part

Now, let's compare this to alternative finishing methods:

Manual Sanding:

- Labor intensive: 8-12 minutes per part

- Inconsistent results across batch

- Estimated cost: $3.50-5.00 per part

Tumble Finishing:

- Long cycle times: 4-8 hours

- Limited geometry access

- Higher equipment cost

- Estimated cost: $2.00-3.50 per part

Chemical Etching:

- Hazardous material handling

- Disposal costs

- Environmental compliance

- Estimated cost: $2.50-4.00 per part

Clearly, glass bead blasting offers significant advantages for medium-volume production. Moreover, the ability to recycle media up to 30 times makes cabinet systems particularly economical.

For small to medium workshops, maximizing cost-effectiveness requires smart practices. First, invest in a quality dust collector to extend media life. Second, segregate media by mesh size to maintain finish consistency. Third, establish standard operating procedures for common part types. Finally, track actual media consumption to identify optimization opportunities.

Additionally, proper maintenance reduces operating costs over time. Clean your blast cabinet regularly to prevent contamination. Replace worn nozzles promptly to maintain efficiency. Furthermore, monitor air pressure consistency to ensure repeatable results.

Conclusion

Achieving precise surface finish Ra values through bead blasting depends on understanding the critical relationships between media selection, process parameters, and material properties. As we've explored throughout this guide, glass bead blasting stands out as a versatile, cost-effective solution for applications requiring controlled finishes between Ra 0.1 and Ra 0.8 micrometers.

The key takeaways include selecting appropriate media size (80-220 mesh for precision work), controlling air pressure (40-100 PSI range), and maintaining consistent blasting distance and angle. Furthermore, glass beads offer significant economic advantages through their reusability, making them ideal for both high-volume production and smaller workshop operations.

Whether you're working on automotive restoration projects, finishing CNC machined components, or preparing surfaces for coating, mastering these parameters ensures consistent, professional results. Therefore, start with conservative settings and gradually adjust until you achieve your target finish. Remember to document your successful parameter combinations for future reference.

Ready to implement these techniques in your shop? Experiment with different combinations of media size, pressure, and distance to find what works best for your specific applications. The investment in understanding these relationships will pay dividends through improved quality, reduced rework, and lower operating costs.

External Links & Resources

[bead blasting surface finish guide][^1]

[glass bead blasting][^2]

[surface finish Ra values][^3]

[abrasive blasting media selection][^4]

[bead blasting cost per part][^5]

[bead blasting parameters for Ra finish][^6]

---

[^1]: Explore this link to understand the techniques and benefits of bead blasting for achieving superior surface finishes.

[^2]: Discover the applications and advantages of glass bead blasting, a popular method for surface preparation and finishing.

[^3]: Understanding Ra values is crucial for achieving desired surface quality in manufacturing processes.

[^4]: Selecting the appropriate media is essential for effective surface preparation and achieving optimal results.

[^5]: Understanding the cost per part for bead blasting can help you budget effectively for your projects.

[^6]: Exploring the parameters for Ra finish will ensure you achieve the desired surface quality in your applications.