Legacy Parts Manufacturing: How Can You Save Equipment When OEM Support Ends?

Legacy Parts Manufacturing: How Can You Save Equipment When OEM Support Ends?

Your production line grinds to a halt. A critical gear in your 15-year-old stamping press has cracked. You call the manufacturer, only to hear those dreaded words: "That model was discontinued eight years ago. We no longer carry spare parts." Suddenly, you're facing a choice between scrapping a perfectly good machine or paying six figures for a replacement. However, there's a third option that many maintenance managers don't know exists.

Quick Facts: Legacy Parts Manufacturing at a Glance

| Quick Facts | Details |

|---|---|

| What is it? | Creating replacement parts for machines when original suppliers stop production |

| Main methods | 3D scanning, reverse engineering, CNC machining, small-batch production |

| Typical cost | $500-$5,000 per part (vs $50,000+ for new equipment) |

| Lead time | 2-6 weeks for first prototype, faster for repeat orders |

| Best for | Equipment with 10+ years remaining life, discontinued parts, low-volume needs |

The good news? Advances in on-demand manufacturing now make recreating obsolete parts both practical and affordable. Instead of treating equipment failure as an inevitable death sentence, smart facility managers are using reverse engineering and small-batch production to keep valuable machines running for years beyond their expected support life.

Table of Contents

1. What Is Legacy Parts Manufacturing and When Does It Make Sense?

2. How Do You Reverse Engineer an Obsolete Part Step by Step?

3. Why Does On-Demand Manufacturing Work Better for Low-Volume Legacy Spares?

4. How Do You Validate Quality When You Don't Have Original Drawings?

5. Conclusion

What Is Legacy Parts Manufacturing and When Does It Make Sense?

Picture this common scenario: Your factory floor holds millions of dollars worth of equipment that still performs perfectly. Yet, one by one, critical components fail with no replacement available. This is where legacy parts manufacturing comes in.

The Core Concept

Legacy parts manufacturing means recreating discontinued components through reverse engineering and small-batch production when OEMs no longer supply them. Instead of relying on dwindling stockpiles or expensive third-party resellers, manufacturers can now reproduce the exact parts they need, when they need them.

Understanding EOL vs End of Support

Here's what most people don't realize: there's a big difference between End of Life (EOL) and end of support. EOL simply means a manufacturer stopped making new machines. End of support means they've also stopped producing spare parts. Therefore, a machine might have 20 years of useful life left, but parts support could vanish after just 7-10 years.

This gap creates a massive problem for industries like industrial machinery and automotive, where equipment investments are meant to last decades. A packaging line that cost $200,000 in 2010 might still produce perfectly in 2026, but finding a replacement servo motor or custom bracket becomes nearly impossible.

The economics change dramatically when you shift from mass production to one-off reproduction. Original parts were cheap because manufacturers spread tooling costs across thousands of units. Consequently, when you need just one replacement, traditional suppliers can't justify the setup expense. On-demand manufacturing solves this by eliminating tooling requirements and using flexible processes like CNC machining.

When does reproduction make sense? Generally, when the equipment still has at least 5-10 years of productive life remaining, and the cost of reverse engineering plus manufacturing is less than 20% of replacement cost. For a $100,000 machine, spending $3,000 to recreate a critical part is an easy decision.

How Do You Reverse Engineer an Obsolete Part Step by Step?

Reverse engineering sounds complex, but it follows a logical workflow. Moreover, you don't need to be an engineer to get started – you just need to understand the process well enough to work with the right supplier.

The Six-Step Process

Process checklist:

✓ Remove and document the failed part

✓ Measure dimensions or 3D scan the component

✓ Rebuild CAD geometry with proper tolerances

✓ Select matching or better materials

✓ Choose CNC, casting, or 3D printing method

✓ Produce prototype and test fit

Step 1: Capturing the Old Part

First, you need to carefully remove the broken component. Take detailed photos from multiple angles before disassembly. Meanwhile, note any wear patterns, as these tell you where stresses concentrate.

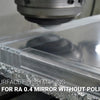

For reverse engineering old machine parts, you have two main options: manual measurement or 3D scanning. Simple parts like bushings, shafts, or brackets can be measured with calipers and micrometers. However, complex geometries benefit enormously from 3D scanning and CAD for legacy components. A quality scan captures thousands of data points in minutes, whereas manual measurement of a complex part might take days.

Step 2: Rebuilding the Geometry

Once you have measurements or scan data, a CAD technician recreates the part digitally. This isn't just tracing – it's intelligent recreation. The technician must decide which dimensions are critical and which can vary. For instance, a bearing seat needs tight tolerances, but a mounting flange might have more flexibility.

Worn parts present a special challenge. If the original part has been eroded or deformed, should you copy the worn geometry or try to reconstruct the original? Usually, the answer is to model what the part looked like when new, using unworn sections as a reference.

Step 3: Material Selection

Without original specifications, material selection requires detective work. Nevertheless, experienced shops can identify materials through hardness testing, spark testing (for metals), and visual inspection. Often, they'll choose a modern equivalent that's easier to source and machine.

For example, if an original part used an obscure steel alloy from the 1990s, a shop might substitute a readily available grade like 4140 steel with similar strength properties. Furthermore, sometimes you can actually improve on the original by selecting materials with better wear resistance or corrosion protection.

Step 4: Manufacturing Route

The final step is choosing how to make the part. CNC machining legacy replacement parts works well for precise metal or plastic components. 3D printing suits complex shapes or rapid prototyping. Traditional casting makes sense for large, simple parts in specific metals.

Each method has trade-offs. CNC machining delivers tight tolerances and excellent surface finish. 3D printing allows complex internal geometries impossible to machine. Casting can be cheaper for bulky components but requires more lead time.

Why Does On-Demand Manufacturing Work Better for Low-Volume Legacy Spares?

The economics of on demand manufacturing for legacy parts are completely different from traditional production. This difference is exactly what makes it viable for spare parts for obsolete equipment.

Breaking the Minimum Order Trap

Traditional manufacturing relies on economies of scale. Tooling up for production might cost $20,000-$50,000. Therefore, to make the math work, you need to spread that cost across hundreds or thousands of units. For legacy parts, this creates an impossible situation – you need one part, but you'd have to order 500.

Cost comparison example:

Traditional tooling setup: $10,000-$50,000 upfront

Minimum order: 500-1,000 pieces

On-demand approach: $0 tooling, order 1-10 pieces, pay only for what you need

The True Cost Calculation

Yes, the per-unit price is higher with on-demand manufacturing. A part that would cost $50 in a production run of 1,000 might cost $800 as a single piece. However, this comparison misses the bigger picture.

Consider this scenario: Your injection molding machine goes down because of a failed hydraulic manifold. The machine produces parts worth $5,000 per day. Every day of downtime costs you that revenue, plus you're still paying operators and overhead.

Option A: Wait 12 weeks for a used part from a broker (if you can find one): Cost = $300,000+ in lost production

Option B: Commission an on-demand replacement in 3 weeks: Cost = $3,000 for part + $105,000 in lost production = $108,000 total

Suddenly, paying $3,000 for a part instead of $300 doesn't seem expensive at all. In fact, it saves you nearly $200,000.

Small Batch Legacy Parts Production Advantages

Another benefit is flexibility. With small batch legacy parts production, you can order exactly what you need. Need one part to fix a broken machine? Order one. Want to keep two spares on the shelf for critical components? Order two.

This approach eliminates inventory risk. Traditional manufacturing forces you to buy hundreds of parts you might never use. Those parts tie up cash, take up storage space, and might become obsolete themselves if you eventually retire the equipment.

Furthermore, lead time often matters more than unit cost. A part that costs $1,200 but arrives in three weeks is vastly superior to a $400 part with a six-month lead time. Every week of delay multiplies your downtime losses.

How Do You Validate Quality When You Don't Have Original Drawings?

Quality validation is the biggest concern most people have about reverse-engineered parts. After all, how do you know a recreated component will actually work?

The Five-Point Validation Protocol

Validation checklist:

1. Test dimensional fit before operation

2. Run at reduced load first

3. Monitor temperature and vibration

4. Document all measurements for future orders

5. Create digital spare parts library

Managing Tolerances Without OEM Specs

Without original engineering drawings, you can't simply check if the part matches the print. Instead, you need a different approach to quality assurance.

Start with dimensional verification. The new part should match critical dimensions within reasonable manufacturing tolerances. For instance, a shaft diameter that mates with a bearing needs to be within 0.001-0.002 inches of nominal. However, a mounting hole might have ±0.010 inches of acceptable variation.

Experienced manufacturers develop an EOL product spare parts strategy that categorizes dimensions by importance:

Critical dimensions: Bearing seats, threaded features, sealing surfaces (±0.001-0.005")

Important dimensions: Overall length, hole locations, width (±0.010-0.020")

Non-critical dimensions: Cosmetic features, large flat surfaces (±0.030"+)

Material Verification Methods

Material validation ranges from simple to sophisticated. Basic approaches include:

Hardness testing: A portable Rockwell tester confirms if the material meets strength requirements

Visual inspection: Color, grain structure, and surface finish reveal material type

Magnet test: Quickly distinguishes between ferrous and non-ferrous metals

For safety-critical parts, you might need more rigorous testing like spectroscopy or tensile testing. Nonetheless, most legacy parts don't require this level of verification.

Prototype Testing Protocols

Never install a reverse-engineered part directly into full production. Instead, follow this staged approach:

Stage 1 – Dimensional Fit (1 day): Install the part without power. Check clearances, alignment, and interference. Make sure bolts thread properly and mating surfaces seat correctly.

Stage 2 – Low Load Testing (3-7 days): Run the equipment at 25-50% of normal production speed and load. Monitor for unusual noise, vibration, or heat. This reveals problems before they cause damage.

Stage 3 – Full Load Validation (2-4 weeks): Gradually increase to full production rates while continuing to monitor performance. By the end of this period, you'll know if the part functions correctly.

Building a Digital Spare Parts Library

Here's where smart companies create long-term value. Once you've successfully reverse-engineered and validated a part, you have something valuable: a complete digital specification.

Store this information systematically:

Final CAD files with all dimensions and tolerances documented

Material specifications and test results

Manufacturing process notes (speeds, feeds, tooling used)

Installation and testing procedures

Supplier contact information and pricing

This library transforms a one-time fix into a repeatable capability. The next time that part fails – or a similar part on another machine – you can reproduce it in days instead of weeks. Additionally, you've eliminated the reverse engineering cost for future orders, making subsequent parts even cheaper.

Conclusion

Legacy parts manufacturing transforms the "scrap or spend $100,000" dilemma into a practical third option that saves both money and valuable equipment. By combining reverse engineering with on-demand production methods, manufacturers can extend the service life of critical machinery by decades, not just years.

The approach works best for equipment that still has substantial productive life remaining, where the combined cost of engineering and manufacturing a replacement part is a small fraction of buying new equipment. For many industrial operations, this means spare parts for obsolete equipment become readily available rather than impossible to source.

Getting started doesn't require a massive commitment. Instead, identify one critical component on legacy equipment where parts availability poses a significant risk. Document the part, work with a supplier experienced in CNC machining legacy replacement parts, and validate the result thoroughly. Once you've proven the process works, you can expand to other vulnerable components across your equipment fleet.

Your next step: Walk your production floor and identify the three machines where a single part failure would cause the most costly downtime. Those are your candidates for legacy parts manufacturing. Don't wait for failure – build your spare parts strategy before you need it.

Recommended Resources

[Legacy parts manufacturing][^1]

[spare parts for obsolete equipment][^2]

[on-demand manufacturing for legacy parts][^3]

[reverse engineering old machine parts][^4]

[CNC machining legacy replacement parts][^5]

[EOL product spare parts strategy][^6]

----

[^1]: A technical guide detailing modern production methods for discontinued components, specifically focusing on the integration of 3D scanning, material analysis, and CNC machining to replicate parts without original CAD data.

[^2]: An authoritative industry resource outlining sourcing strategies for end-of-life industrial machinery, including the use of specialized dismantling networks, global surplus platforms, and reconditioning best practices.

[^3]: An authoritative guide by Dassault Systèmes exploring how on-demand manufacturing platforms utilize digital twins and distributed supplier networks to solve obsolescence issues, effectively reducing inventory costs and lead times for discontinued industrial components.

[^4]: A detailed technical resource outlining the four-step workflow for hardware reverse engineering, focusing on high-precision 3D scanning, point cloud post-processing, and parametric CAD modeling to recreate or improve aging mechanical parts with missing documentation.

[^5]: An industry-standard resource from FANUC detailing how CNC retrofitting and precision machining can breathe new life into legacy equipment, offering a cost-effective alternative to full machine replacement while improving accuracy and reducing cycle times by up to 50%.

[^6]: A comprehensive strategic guide for manufacturers on managing End-of-Life (EOL) parts, covering proactive monitoring, "Last Time Buy" (LTB) tactics, and digital workflow optimization to prevent costly production downtime caused by discontinued components.