How Does 5-Axis CNC Machining Cut Mold Delivery Time by 60% for Consumer Products?

Time is money in the consumer products industry. When your competition launches a new smartphone model or kitchen appliance weeks before you do, market share slips away. The biggest bottleneck? Mold production. Traditional machining methods force manufacturers to wait months for complex molds, missing critical market windows. However, a proven technology is changing this reality. Leading manufacturers now rely on advanced machining capabilities that deliver finished molds in half the time without sacrificing quality.

⚡ Quick Answer: What You Need to Know

Before we dive deep, here are the most important facts about 5-axis CNC technology for mold making:

| Key Benefit | Impact on Your Production |

|---|---|

| Delivery Speed | 60% faster compared to traditional 3-axis methods |

| Setup Time | Single setup handles complete complex geometries |

| Surface Quality | Reduces polishing time by 40-70% |

| Cooling Design | Conformal cooling channels cut cycle times by 20-40% |

| Precision Level | Achieves tolerances of ±0.005mm consistently |

| Applications | Phone cases, appliance housings, cosmetic packaging |

These numbers aren't marketing hype. They represent real-world results from manufacturers who have adopted this technology for consumer product mold development.

The consumer electronics and appliance markets move incredibly fast. Moreover, product designs keep getting more complex with sleek curves, hidden fasteners, and integrated features. Traditional 3-axis machining simply cannot keep pace with these demands. Therefore, understanding how 5 axis CNC consumer mold making works becomes critical for any manufacturer who wants to stay competitive. Let's explore exactly how this technology delivers such dramatic improvements.

Table of Contents

- What Makes 5-Axis CNC Different for Consumer Product Mold Making?

- Why Does Single-Setup Machining Save So Much Time?

- How Does 5-Axis Machining Create Better Surface Finishes for Consumer Molds?

- What Are Conformal Cooling Channels and Why Do They Matter?

What Makes 5-Axis CNC Different for Consumer Product Mold Making?

Understanding the Fundamental Difference

When you look at a traditional milling machine, it moves cutting tools along three perpendicular axes. Think of it like an Etch A Sketch that only moves left-right, forward-backward, and up-down. Consequently, accessing angled surfaces or undercuts requires manually rotating your workpiece multiple times. In contrast, 5-axis machines add two rotational movements to these three linear axes. This capability transforms what's possible in a single setup.

The Core Advantages at a Glance

Key benefit: The machine simultaneously controls movement on five axes (X, Y, Z plus two rotational axes labeled A and B).

Result: Your cutting tool reaches undercuts, angled features, and complex curves without any repositioning of the mold base.

Common applications: Mobile phone case molds with camera bumps, appliance housings with complex parting lines, and cosmetic packaging with organic shapes all benefit tremendously.

How Rotational Capability Changes Everything

The two additional rotational axes create something remarkable. Imagine trying to sand a rounded surface with your arm locked straight—you'd constantly need to reposition yourself. Similarly, 3-axis machines must stop and reposition the workpiece to reach different angles. The cutting tool approaches from virtually any angle with 5-axis capability, maintaining optimal contact throughout the entire machining process.

Here's a concrete example using a smartphone case mold. These molds typically feature camera bumps that protrude at specific angles, button cutouts along the sides, and subtle texture on the back surface. Furthermore, many designs include undercut features where the plastic "wraps around" slightly to create snap-fit assembly points. A 3-axis machine would require at least four separate setups to machine all these features. Each setup takes 45-90 minutes just for positioning and verification. Additionally, every time you move the workpiece, you introduce potential alignment errors.

With 5 axis CNC for mobile phone case mold production, the entire process happens in one continuous operation. The spindle tilts and rotates to access the camera bump area, then smoothly transitions to cut the button holes from the side, and finally machines the undercut snap features—all while the mold base stays firmly clamped in its original position. This isn't just convenient; it fundamentally changes the economics of complex mold machining.

Why Does Single-Setup Machining Save So Much Time?

The Hidden Cost of Setup Time

Many people focus on cutting speed when comparing machining methods. However, the real time sink in traditional mold making isn't the actual cutting—it's everything that happens between cuts. Setup time represents one of the largest sources of waste in manufacturing.

The Numbers Tell the Story

Traditional method: Complex consumer product molds typically require 4-6 different setups to access all necessary surfaces and features.

5-axis method: The exact same mold completes in just 1 setup from start to finish.

Time saved: Each setup consumes 1.5-2 hours on average, which means 8-12 hours saved per mold through reducing mold delivery time alone.

Accuracy boost: Eliminating multiple repositioning operations removes cumulative positioning errors that plague traditional methods.

Walking Through a Real-World Example

Let's follow a typical mobile phone case mold through both processes. The design includes a main cavity, camera lens opening with a raised ring, four side button cutouts, charging port opening at the bottom, and internal snap-fit bosses. Additionally, the back surface needs a subtle texture pattern.

Traditional 3-axis approach:

- Setup 1: Machine the main cavity from the top (2 hours setup + 4 hours machining)

- Setup 2: Flip the mold 180 degrees to machine the back surface texture (1.5 hours setup + 2 hours machining)

- Setup 3: Rotate 90 degrees to machine button cutouts on the left side (1.5 hours setup + 1.5 hours machining)

- Setup 4: Rotate another 90 degrees for the right side buttons (1.5 hours setup + 1.5 hours machining)

- Setup 5: Position at an angle to reach the camera opening (2 hours setup + 3 hours machining)

- Setup 6: Access internal snap features requiring special angled approach (1.5 hours setup + 2 hours machining)

Total time: 10 hours of pure setup + 14 hours of machining = 24 hours

5-axis CNC approach with advanced machining services:

- Setup 1: Secure the mold block (1 hour setup)

- Continuous machining of all features with automatic tool orientation changes (8 hours machining)

Total time: 1 hour setup + 8 hours machining = 9 hours

That's a 15-hour difference on a single mold. When you're producing dozens of molds per month, these hours multiply into weeks of capacity. Moreover, the single-setup approach maintains a consistent reference point throughout the entire process. Every feature relates back to the original datum, which means tighter dimensional relationships between features.

Think about what happens with multiple setups. Each time you remove and replace the workpiece, you introduce tiny positioning variations—maybe 0.01mm here, 0.015mm there. These errors compound. By the sixth setup, your accumulated error might reach 0.05mm or more. For high precision mold manufacturing where tolerances of ±0.01mm are standard, this becomes unacceptable. Single-setup machining eliminates this problem entirely.

How Does 5-Axis Machining Create Better Surface Finishes for Consumer Molds?

Why Surface Quality Matters So Much

The quality of your mold surface directly transfers to every part produced from that mold. A rough mold surface means rough parts that require additional finishing. Additionally, poor surface finish in the mold can create flow problems during injection molding, leading to visual defects like flow lines or surface blemishes. Therefore, achieving excellent mold surface quality saves time and money throughout the entire production process.

The Technical Advantages Explained Simply

Shorter cutting tools possible: Because the spindle tilts to approach the work at optimal angles, you can use much shorter cutting tools.

Less tool deflection means smoother surfaces: Shorter tools are significantly stiffer, which reduces vibration and deflection during cutting.

Optimal cutting angles maintained: The tool stays perpendicular to complex curved surfaces throughout the entire tool path.

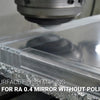

Polishing time reduced dramatically: Many surfaces come off the machine with such high quality that polishing time drops by 40-70%.

The Physics Behind Better Finishes

Let's make this simple. When you use a long cutting tool, it acts like a diving board. The longer it extends from the spindle, the more it can flex and vibrate. This flexing creates tiny variations in the cutting depth, which show up as chatter marks—those wavy lines you see on poorly machined surfaces.

Traditional 3-axis machines often need long tools because they must reach deep into cavities while approaching from only one direction (straight down). Consequently, a tool might extend 4-5 inches from the tool holder to reach the bottom of a deep phone case cavity.

With 5-axis capability, the spindle tilts to approach the same feature from the side. Now you only need a 2-inch tool extension to reach the exact same spot. This shorter tool is roughly four times stiffer (stiffness increases with the cube of the length reduction). Therefore, it resists deflection much better, produces far less vibration, and creates a dramatically smoother surface.

Furthermore, the ability to maintain perpendicular contact matters enormously on curved surfaces. Imagine trying to sand a sphere with sandpaper—you get the best results when the sandpaper contacts the surface at a 90-degree angle. Similarly, cutting tools work most effectively when perpendicular to the surface they're machining. On a curved phone case cavity, a 3-axis tool approaches at varying angles, sometimes cutting with the side of the tool where geometry is less than ideal. A 5-axis tool constantly adjusts its orientation to maintain that perfect perpendicular approach throughout the entire curve.

The benefits of 5-axis machining for appliances become especially clear when producing molds for visible surfaces. Consider a kitchen appliance housing with a glossy, curved front panel. This surface must be absolutely flawless because consumers see it every day. With traditional machining, achieving the necessary surface finish might require 6-8 hours of skilled hand polishing. With 5-axis machining, the as-machined surface quality is so good that polishing might only take 2-3 hours. That labor savings repeats with every mold you produce.

What Are Conformal Cooling Channels and Why Do They Matter?

The Critical Role of Cooling Design

Most people think mold making ends when the cavity is machined. However, what happens inside the mold—specifically how heat is removed during injection molding—dramatically affects both production speed and part quality. Cooling design represents one of the most impactful yet often overlooked aspects of mold performance.

Understanding the Difference

Traditional cooling: Straight drilled holes running through the mold base, often far from the cavity surface in some areas and close in others.

Conformal cooling: Channels that follow the precise contours of the mold cavity, maintaining consistent distance from the molding surface.

Benefits of conformal cooling: Cycle times drop by 20-40%, warpage reduces significantly, sink marks and other cooling-related defects nearly disappear.

Only possible with: Advanced conformal cooling channel machining using 5-axis CNC technology.

Why Cooling Uniformity Changes Everything

When plastic flows into a mold cavity, it arrives hot—typically between 200-300°C depending on the material. The mold must remove this heat so the part solidifies and can be ejected. How quickly and uniformly this happens determines three critical factors: cycle time (your production rate), dimensional accuracy (whether parts meet specifications), and visual quality (whether defects appear).

Traditional straight-drilled cooling channels create uneven cooling. Picture a phone case mold with a flat back and a protruding camera bump. A straight cooling channel might pass 10mm beneath the flat back area but end up 25mm away from the camera bump because it protrudes. The flat area cools quickly while the bump stays hot much longer. This uneven cooling causes the part to warp as it cools, and it significantly increases the time needed before the part becomes solid enough to eject.

Conformal cooling channels solve this by following the shape of the part. The channel curves to stay 8mm beneath both the flat back and the camera bump. Heat removes uniformly across the entire part. Consequently, the part cools faster overall (because no area needs to wait for the slowest-cooling section), and it cools evenly (eliminating warpage).

Here's the challenge: creating these complex 3D curved tunnels inside a block of steel. These aren't simple straight holes you can drill. They're elaborate pathways that twist and turn to match your part geometry. Some sections might run horizontally, then curve upward at a 35-degree angle, then spiral around a boss feature. This type of geometry is virtually impossible with traditional machining methods.

5-axis CNC makes it possible through simultaneous control of all five axes. The machine can position a specialized milling cutter at any angle and drive it through the mold base along these complex 3D paths. It's like threading a needle through a maze, except the needle is cutting its own path as it goes. The 5-axis CNC machining efficiency enables mold makers to create cooling systems that were purely theoretical just a decade ago.

For consumer products where production volumes are high, this cooling improvement pays massive dividends. Consider injection molding phone cases at a rate of 1,000 units per day. If traditional cooling requires a 35-second cycle time but conformal cooling cuts that to 25 seconds, you've just increased daily capacity by 40% using the same press. Over a year, that's the equivalent of adding months of production capacity without buying additional equipment.

Moreover, the quality improvements matter just as much. Warped phone cases don't fit properly on phones—they're scrap. Sink marks on visible appliance surfaces create customer complaints. By enabling conformal cooling design, 5-axis machining doesn't just speed up production; it also significantly reduces defect rates and improves the final product quality that reaches consumers.

Conclusion

The transition from traditional 3-axis machining to 5-axis CNC technology represents more than just an equipment upgrade. It fundamentally changes what's possible in consumer product mold production. The 60% reduction in delivery time isn't an isolated benefit—it emerges naturally from the combination of single-setup capability, superior surface finishes, and advanced features like conformal cooling channels that this technology enables.

Wrapping Up the Key Advantages

Throughout this article, we've examined how 5-axis technology addresses the biggest challenges in mold making. Single-setup machining eliminates the hours wasted repositioning workpieces while simultaneously improving dimensional accuracy. The ability to use shorter, stiffer cutting tools creates surface finishes that dramatically reduce polishing labor. Furthermore, the capability to machine complex internal geometries opens the door to conformal cooling designs that speed up production and improve part quality.

These advantages compound. Faster delivery means you can take on more projects per year. Better surface quality reduces labor costs and speeds up mold delivery even further. Conformal cooling improves the performance of the molds you deliver, making your customers more successful and more likely to return for future projects.

The technology is also becoming increasingly accessible. While 5-axis machines commanded premium prices a decade ago, increased competition and improved manufacturing methods have brought costs down significantly. For mold shops serving the consumer products market—whether producing molds for electronics, appliances, cosmetics, or other high-volume consumer goods—the return on investment calculation has become compelling.

If your shop specializes in complex geometries, tight tolerances, or fast-turnaround projects, 5-axis capability has likely shifted from a luxury to a competitive necessity. The manufacturers winning contracts today are those who can deliver complex, high-quality molds in timeframes that seemed impossible just a few years ago.

External Links & Resources

[5 axis CNC consumer mold making][^1]

[consumer product mold development][^2]

[complex mold machining][^3]

[5 axis CNC for mobile phone case mold][^4]

[conformal cooling channel][^5]

---

[^1]: Explore this link to understand how 5 axis CNC technology enhances precision and efficiency in mold making.

[^2]: This resource will provide insights into effective strategies for developing high-quality consumer product molds.

[^3]: Explore advanced techniques in complex mold machining to improve your manufacturing processes and product quality.

[^4]: Discover how 5 axis CNC technology enhances precision and efficiency in mobile phone case mold production.

[^5]: Explore this link to understand how conformal cooling channels enhance manufacturing efficiency and product quality.